A corrugated foil type air dynamic pressure bearing

An aerodynamic pressure bearing, corrugated foil type technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of limited damping level, low load capacity, engine reliability and life reduction, etc., to achieve increased stability performance, low friction and wear, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The corrugated foil type air dynamic pressure bearing provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

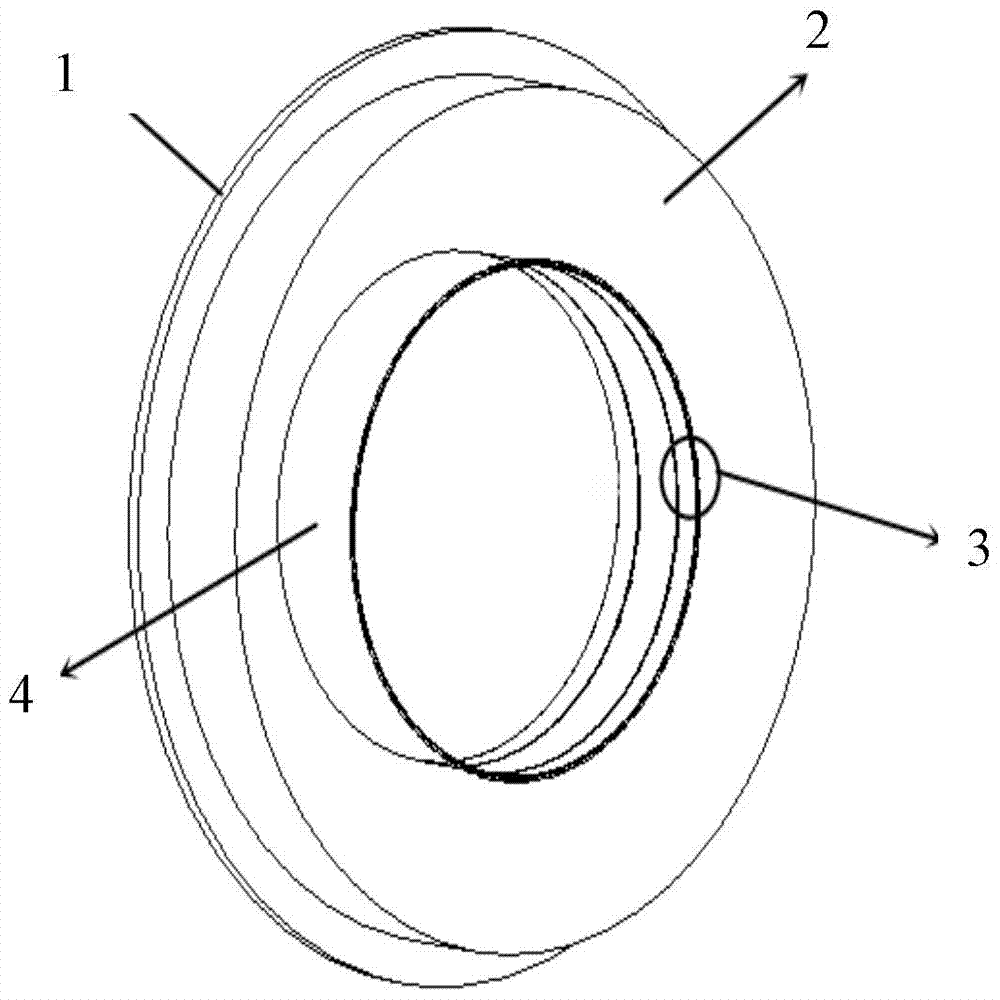

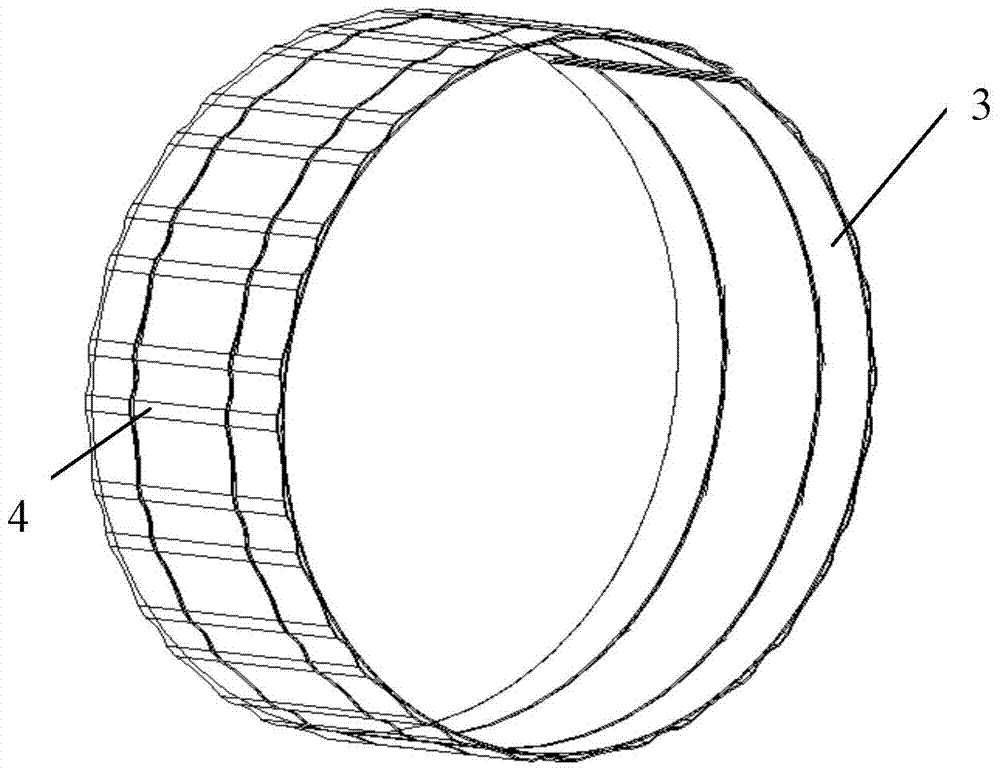

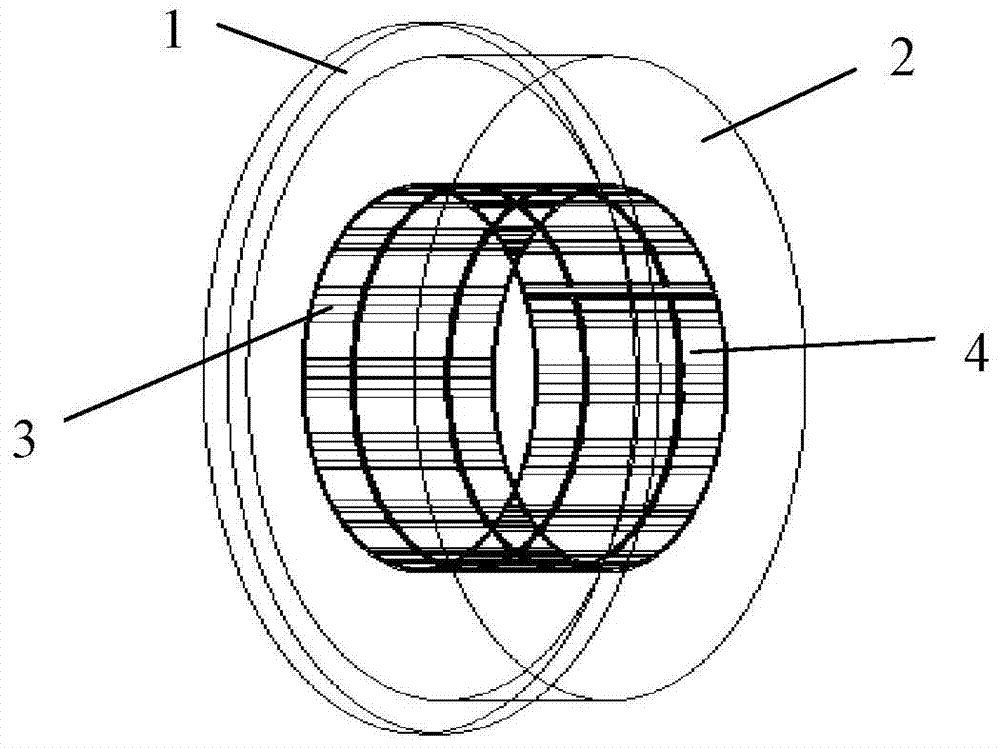

[0017] like figure 1 — Figure 4 As shown, the corrugated foil type air dynamic pressure bearing provided by the present invention includes a shoulder 1, a bearing housing 2, a flat foil 3 and a plurality of corrugated foils 4; wherein the bearing housing 2 is in the shape of a ring; the protruding shoulder 1 is It is formed by extending radially outward from one end edge of the bearing housing 2 to fix and transmit loads; the flat foils 3 are arc-shaped, and a plurality of flat foils 3 are arranged side by side, and the adjacent flat foils 3 The edges on both sides overlap each other to maintain sufficient strength; the corrugated foil sheet 4 is also in the shape of an arc, on which there are a plurality of two corrugations arranged alternately and with different radii of curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com