Water-lubricated two-way working thrust bearing device

A thrust bearing, two-way working technology, applied in sliding contact bearings, bearings, bearing components, etc., can solve problems such as parts that damage thrust bearings, bearing failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

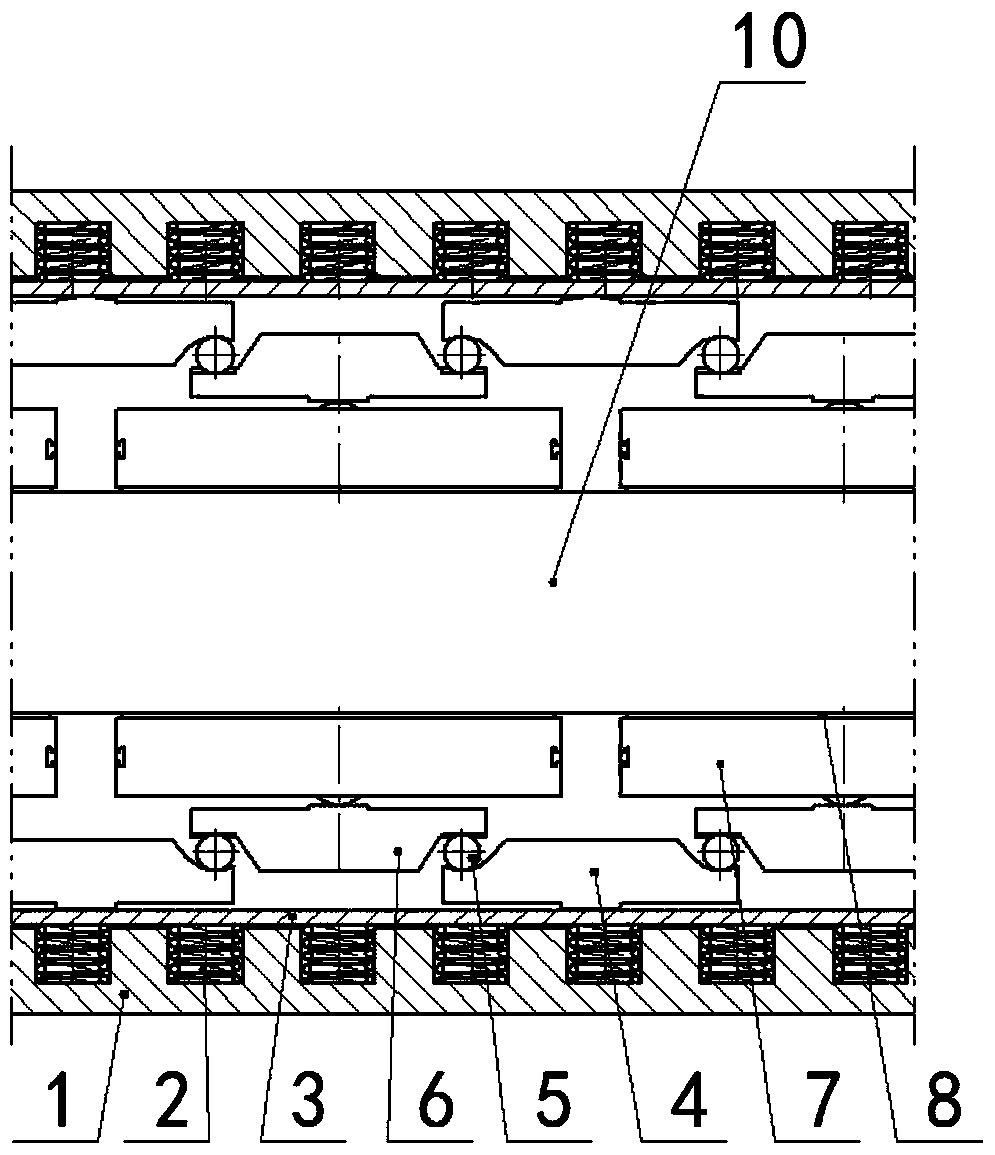

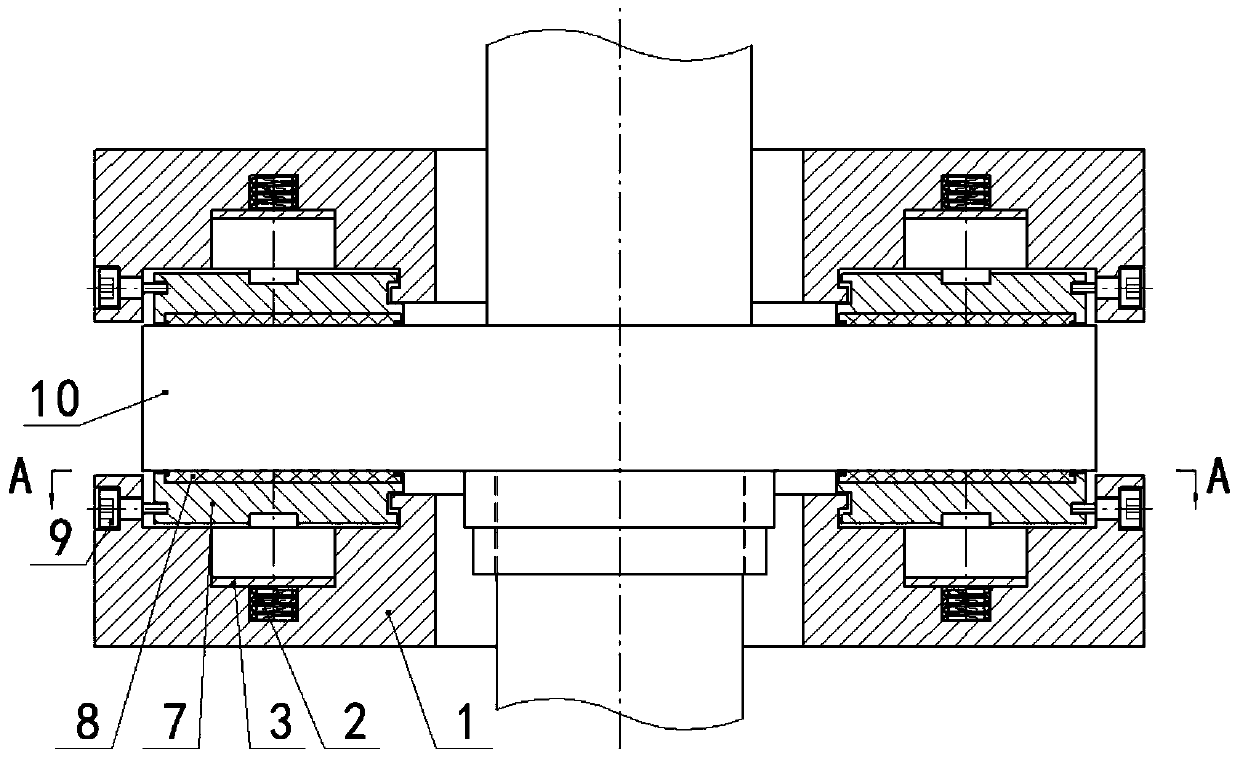

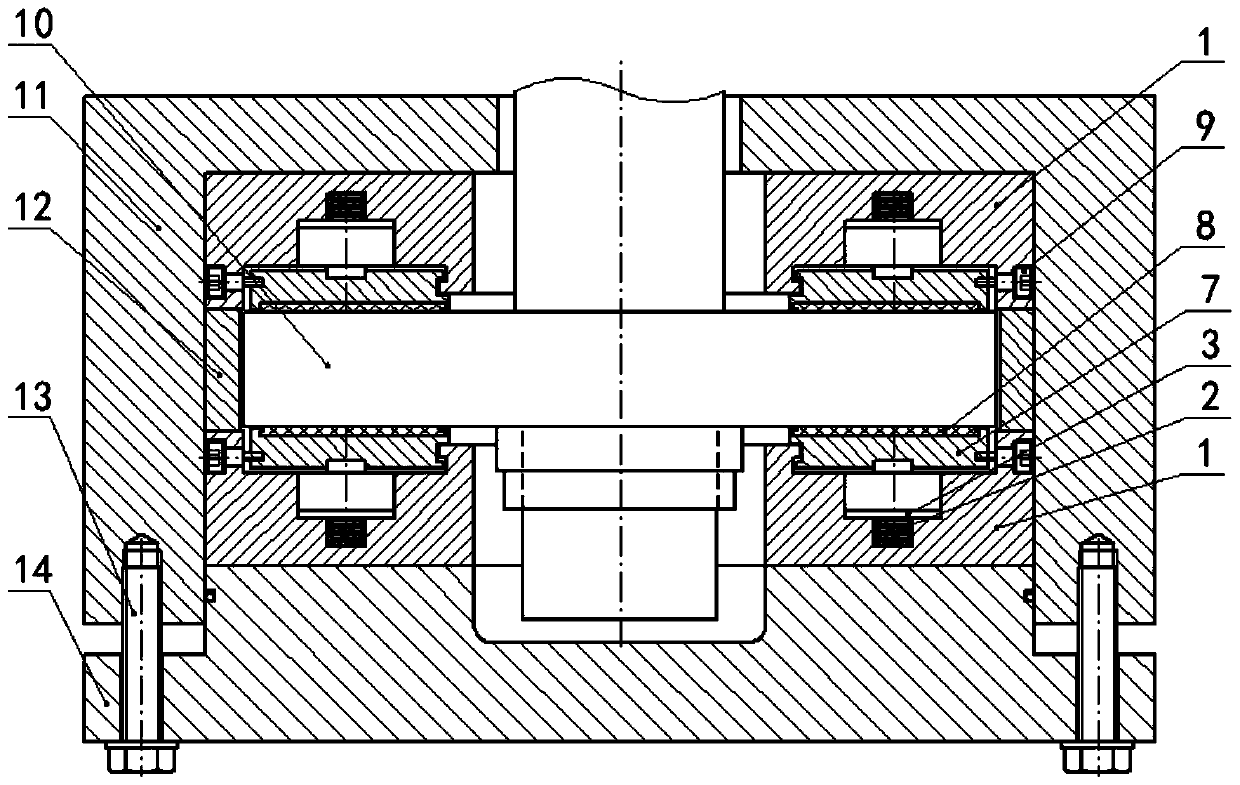

[0012] Such as figure 1 Shown is a water-lubricated bidirectional working thrust bearing device, the bearing housing 1 is a symmetrical structure of upper and lower, wherein the pre-tensioning spring 2 is installed in the spring cavity of the bearing housing 1, and the pre-tensioning spring 2 is press-mounted on the track ring plate 3; Such as figure 2 As shown, the lower balance weight 4 and the upper balance weight 6 are circumferentially connected by rollers 5 to form an annular structure and are stacked on the track ring plate 3 in the axial direction; Figure 4 As shown, the thrust pad 8 is inlaid on the thrust bearing base 7; the thrust bearing base 7 is installed on the upper balance block 6, and the side is limited by the positioning pin 9 and the bearing seat 1; the thrust head 10 is installed on the bearing seat 1. In the middle, a gap is provided between the bearing seat 1 and the track ring plate 3, a sleeve 12 is arranged between the bearing seat 1, and the motor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com