Improvements in refrigerators

A technology for refrigerators and air inlets, which is applied in household refrigeration devices, display cabinets, cooling fluid circulation devices, etc., can solve the problems of multi-energy and consumption, reduce turbulence and infiltration, and improve the efficiency of refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

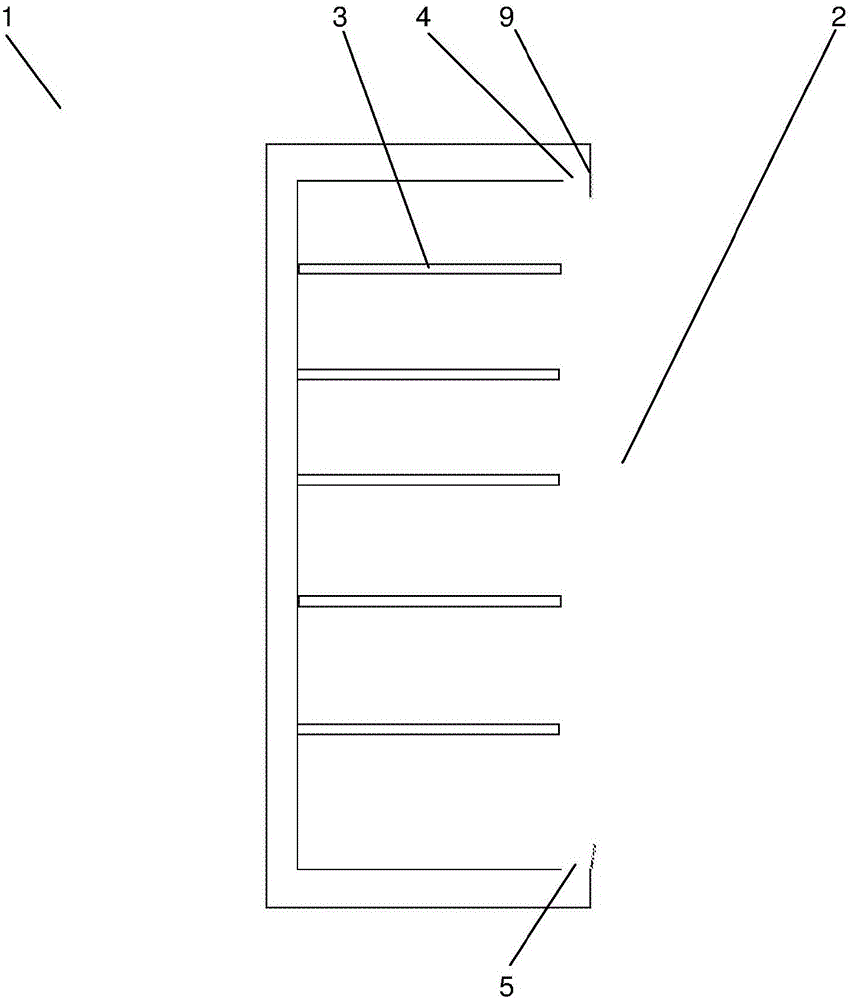

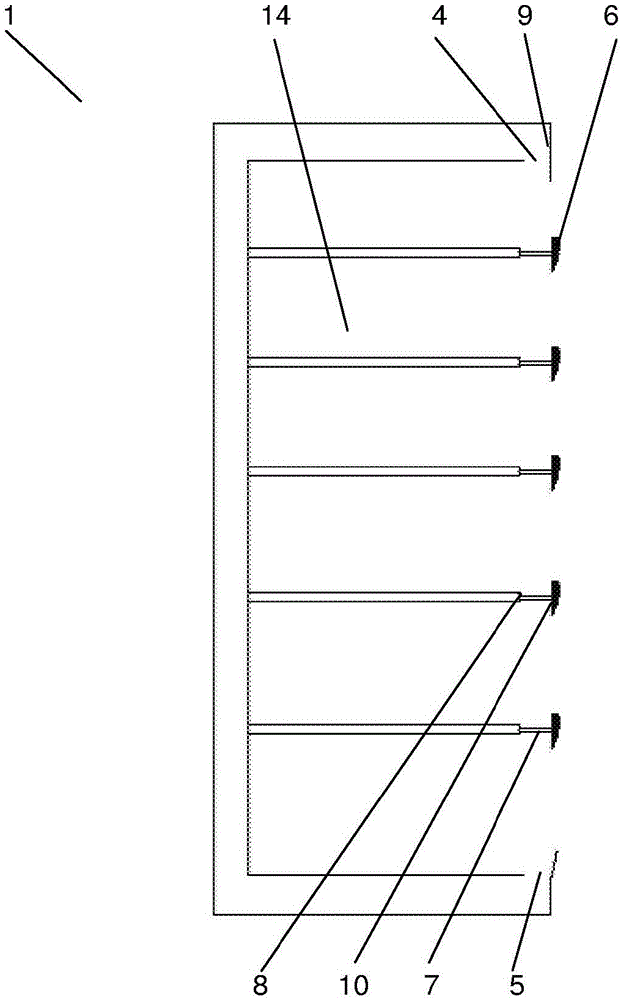

[0090] See attached picture, figure 1 A standard front-loading refrigerator 1 is shown with an open front 2 and a plurality of shelves 3 . The refrigerator 1 comprises an air curtain system having an air outlet 4 located above the open front of the refrigerator and a return air inlet 5 located below the outlet 4 at its top.

[0091] There are various other components of air curtain systems, but such systems are well known in the art, so further discussion of it is not deemed necessary.

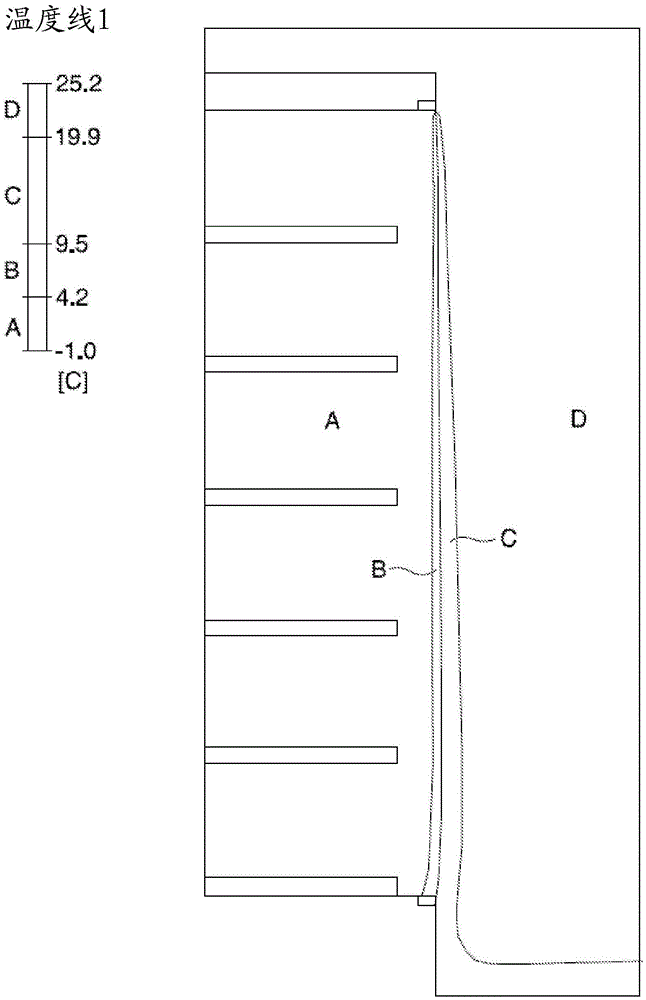

[0092] The air curtain system of the refrigerator 1 is suitable for making the air curtain of cooling air blow between the air outlet 4 and the return air inlet 5 , so that the air curtain blows in front of the shelf 3 to improve the efficiency of the refrigerator 1 .

[0093] The air outlet 4 has an outer edge 9 , so that the air curtain discharged from the air outlet 4 has its front edge substantially aligned with the outer edge 9 immediately after leaving the air outlet 4 .

[0094] but i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com