Blending modified silica emulsion coated diammonium phosphate slow-release compound fertilizer and preparation method thereof

A technology of coating diammonium phosphate and slow-release compound fertilizer, which can be used in fertilizer mixtures, fertilization devices, agriculture, etc., can solve the problems of poor elasticity, poor slow-release performance of fertilizers, and it is difficult to control and release nutrients. Convenient operation, efficient utilization, and the effect of industrialized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

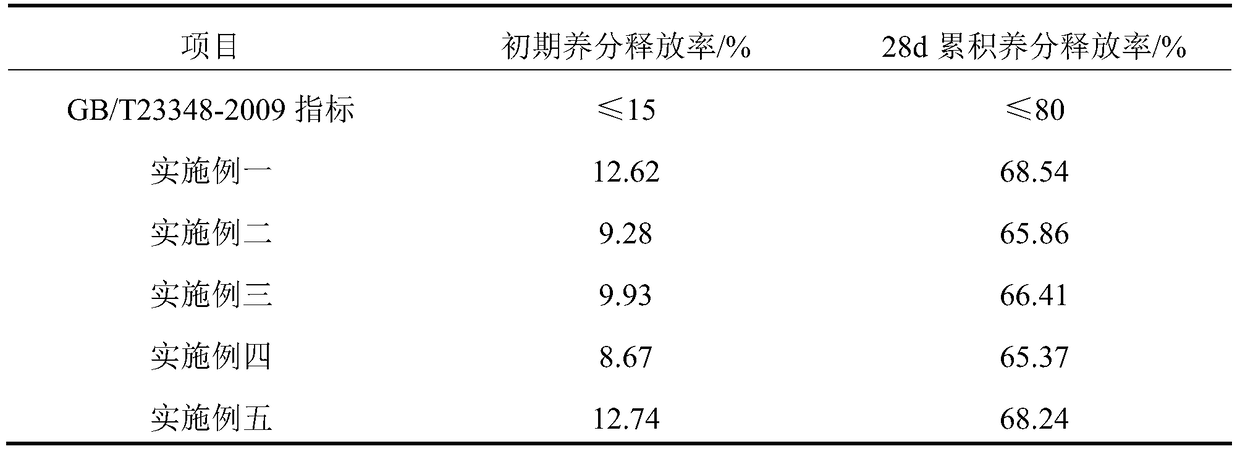

Examples

Embodiment 1

[0025] Mix 40g of polyvinyl alcohol aqueous solution with a mass concentration of 4% and 0.35g of sodium carboxymethylcellulose in a water bath at a temperature of about 85°C and a stirring speed of 1075rpm until they are completely dissolved, and then add 0.04g of organic silicon Foaming agent and stir for about one minute, then add 0.7g of glycerol, stir and mix at high speed for 2 minutes, then add 6.1g of silica powder and stir and mix at high speed for about 30 minutes to prepare a blended modified silica emulsion, choose 2 ~ 4mm The diammonium phosphate granular fertilizer was preheated at 60°C for 4 minutes, and then the prepared blended modified silica emulsion was atomized and sprayed on its surface for many times, and the coated particles were subjected to hot air at 90°C. After drying and cooling at room temperature, the spray coating amount accounts for 36.48% of the total weight of the uncovered fertilizer, and finally spray paraffin wax solution on the surface, an...

Embodiment 2

[0027] Mix 40g of polyvinyl alcohol aqueous solution with a mass concentration of 4.5% and 0.4g of sodium carboxymethylcellulose in a water bath at a temperature of about 85°C and a stirring speed of 992rpm until they are completely dissolved, and add 0.04g of organic silicon disinfectant Foam agent and stir for about one minute, then add 0.8g of glycerol, stir and mix at high speed for 2 minutes, then add 5.2g of silica powder and stir and mix at high speed for about 30 minutes to prepare a blended modified silica emulsion, choose 2 ~ 4mm The diammonium phosphate granular fertilizer was preheated at 65°C for 4 minutes, and then the prepared blended modified silica emulsion was atomized and sprayed on the surface for several times, and the coated particles were dried by hot air at 99°C , after cooling at room temperature, the spray coating amount accounts for 42.53% of the total weight of the uncovered fertilizer, and finally spray paraffin wax solution on its surface, and the ...

Embodiment 3

[0029] Mix 40g of polyvinyl alcohol aqueous solution with a mass concentration of 5% and 0.4g of sodium carboxymethylcellulose in a water bath at a temperature of about 85°C and a stirring speed of 1049rpm until they are completely dissolved, and add 0.04g of organic silicon disinfectant Foam agent and stir for about one minute, then add 0.8g of glycerol, stir and mix at high speed for 2 minutes, then add 6.8g of silica powder and stir and mix at high speed for about 30 minutes to prepare a blended modified silica emulsion, choose 2 ~ 4mm The diammonium phosphate granular fertilizer was preheated at 65°C for 4 minutes, and then the prepared blended modified silica emulsion was atomized and sprayed on the surface for several times, and the coated particles were dried by hot air at 103°C , after cooling at room temperature, the spray coating amount accounts for 37.89% of the total weight of the uncovered fertilizer, and finally spray paraffin wax solution on its surface, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com