Method for cutting Mach surface of hypersonic aircraft with forebody/air inlet pipeline in integrated design

A technology of hypersonic speed and cutting method, which is applied in the combustion direction of the intake port of the power plant, and can solve the problem of large shock wave resistance on the compression surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

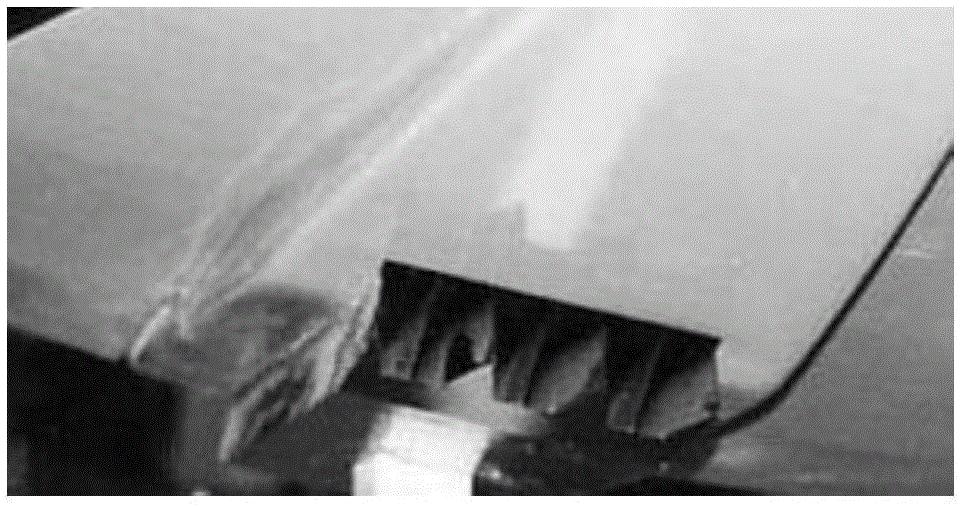

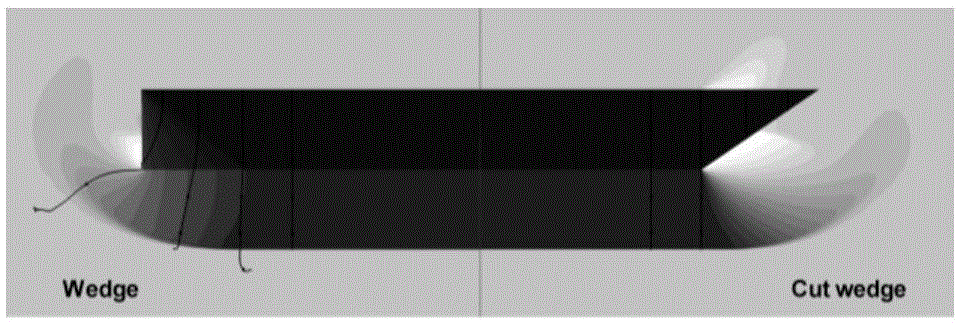

[0038] Example : Design Mach number Ma=5 for incoming flow, Mach number Ma=2 for inlet outlet outlet. The integrated precursor / intake channel designed according to the Mach surface cutting method provided by the present invention is as follows: Figure 4 and Figure 5 shown. In this example, the inlet 3 of the air inlet is a rectangular cross-section inlet, and the designed compression surface is a four-stage compression surface, wherein the third and fourth compression surfaces are arranged inside the lip, and the first and fourth stages are arranged on the front body. Secondary compression face.

[0039]The design method of the compression surface inside the lip is as follows: start from the lower edge of the inlet 3, reverse the flow direction, that is, trace the edge 5 of the fourth-stage compression surface upstream to obtain the fourth-stage compression surface, and the edge 6 of the fourth-stage compression surface The position should be such that the shock wave ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com