Calibration method, calibrating device, and calibration method of calico printing machine sprayer head

A calibration method and a calibration device technology, which are applied in printing, electrical components, image communication, etc., can solve the problems of inability to adapt to pattern change speed, high cost of plate making, poor reliability of nozzles, etc., achieve simple and rapid adjustment process, overcome installation Accuracy Issues, Calibration Precise and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0039] Calibration method of the present invention comprises:

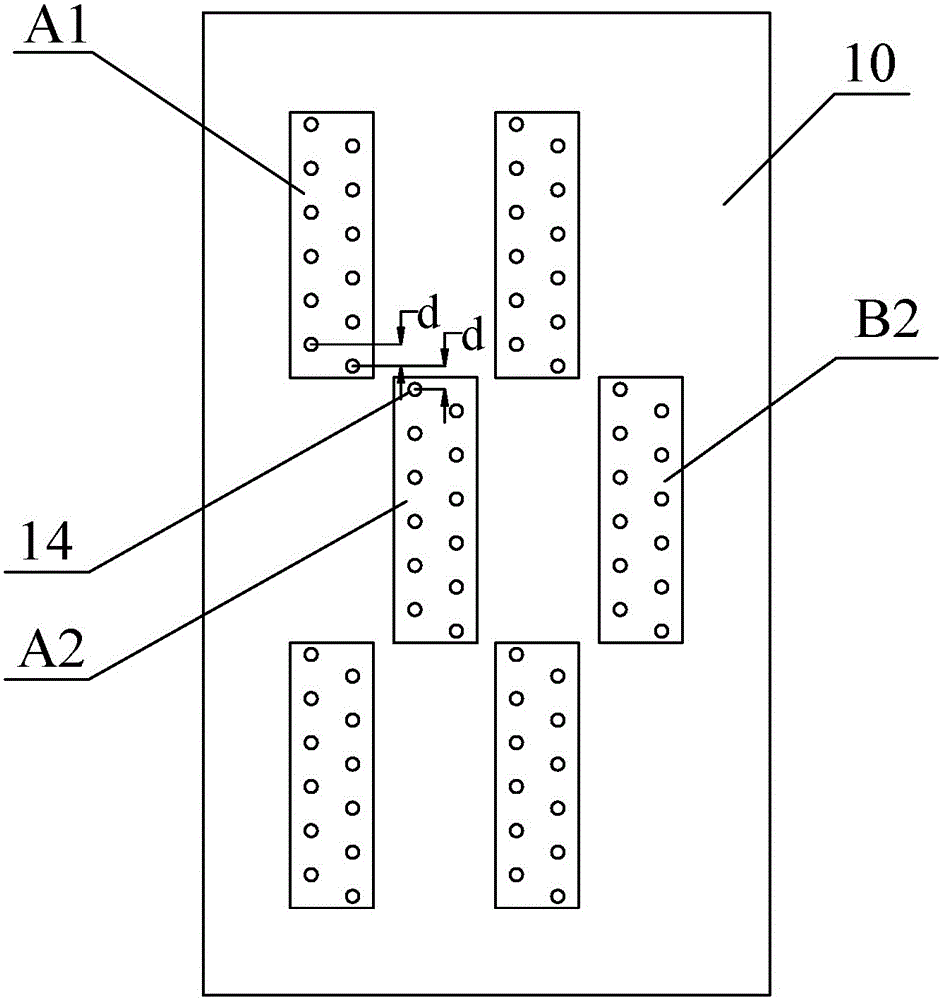

[0040] Use the camera device to shoot the target object to be calibrated;

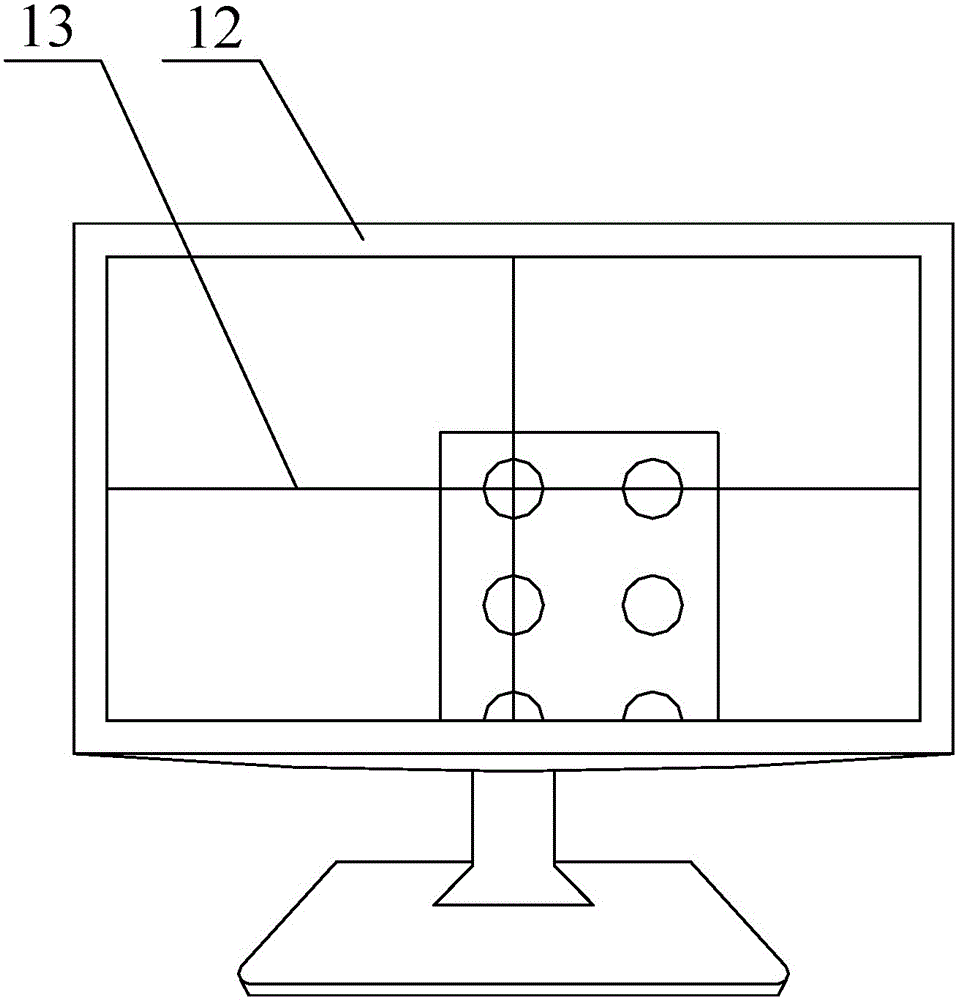

[0041] Outputting the image captured by the camera device to the display device, the display device is provided with a reference mark;

[0042] moving the camera device so that the position of the first reference point on the target object displayed on the display device is aligned with the reference mark;

[0043] Adjusting the position of the target object so that the position of the second reference point on the target object displayed on the display device is aligned with the reference mark.

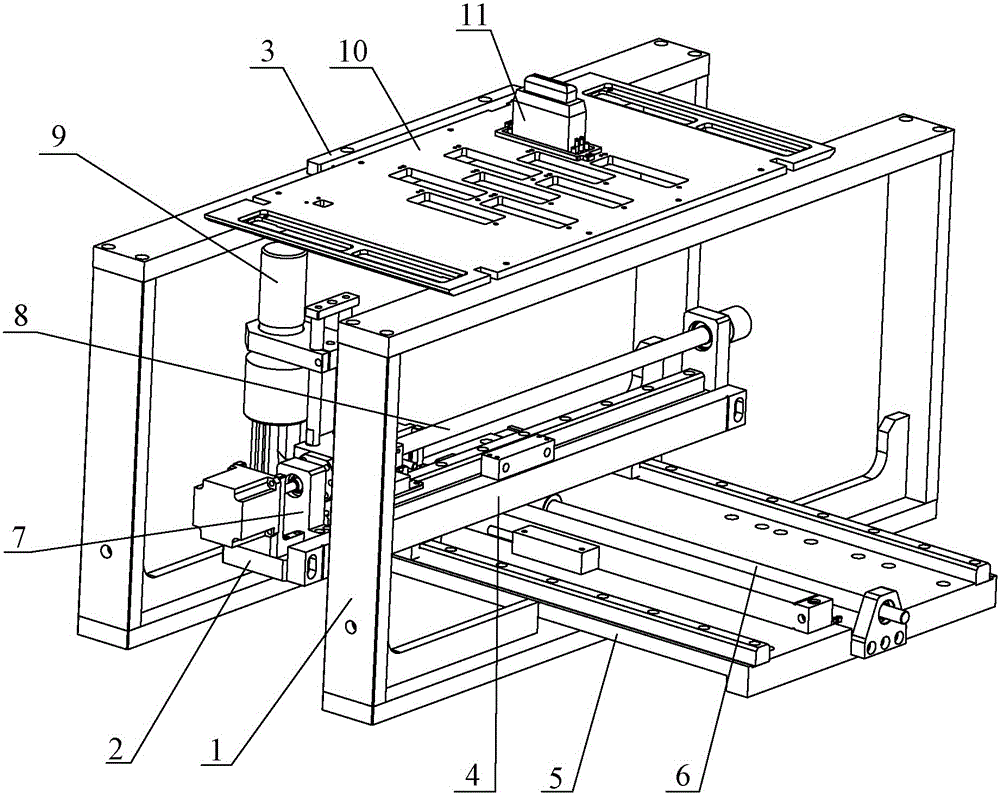

[0044] Calibration device of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com