Installing tool for rear oil seal of crankshaft

A technology for installing tools and oil seals, which is applied in the field of installation tools for crankshaft rear oil seals, can solve the problems of poor tool versatility and achieve good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

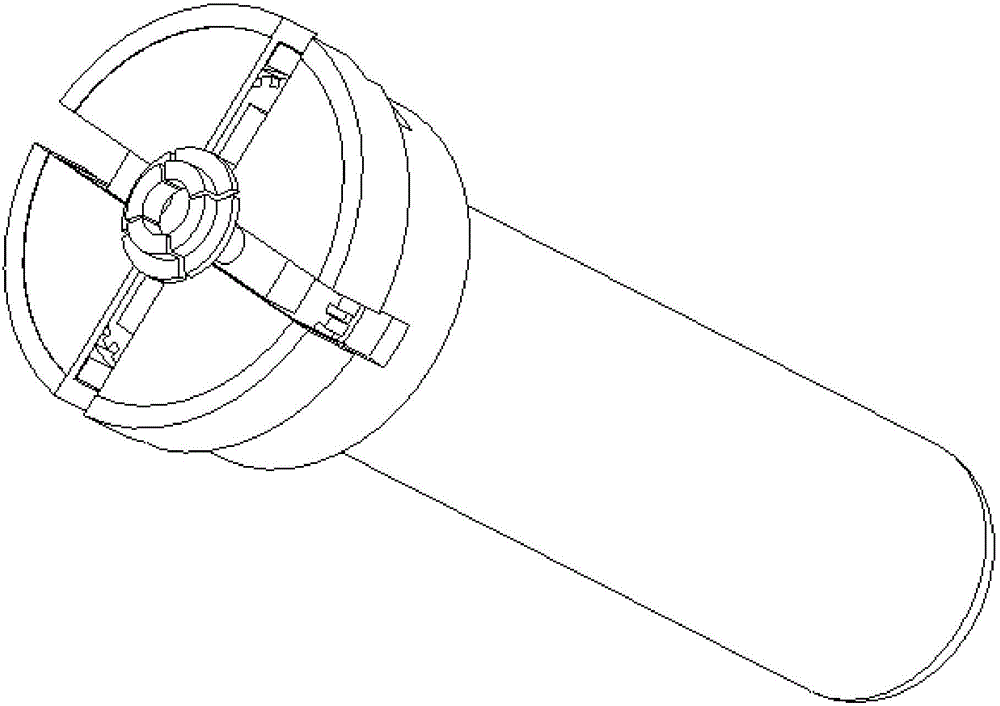

[0029] Such as Figure 2-6 As shown, the embodiment of the present invention provides an installation tool for the crankshaft rear oil seal. The installation tool is used for press-fitting the crankshaft rear oil seal. The main body 11 can adopt a columnar structure, one end of which is the hitting end, and the other end is equipped with a driving disc 12, a guide disc 13 and an oil sealing block 14.

[0030] The drive disc 12 is rotatably mounted on the main body 11, and its rotation direction is perpendicular to the pressing direction of the rear oil seal of the crankshaft. The end face of the drive disc 12 has helical teeth. The guide plate 13 is mounted on the body 11 and has a plurality of guide grooves thereon. There are multiple oil seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com