A method of motor maintenance

A technology of motor rotor and pole beam, applied in the field of motor maintenance, can solve the problems of irreparable, economic loss, etc., and achieve the effect of overcoming the difficulty of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

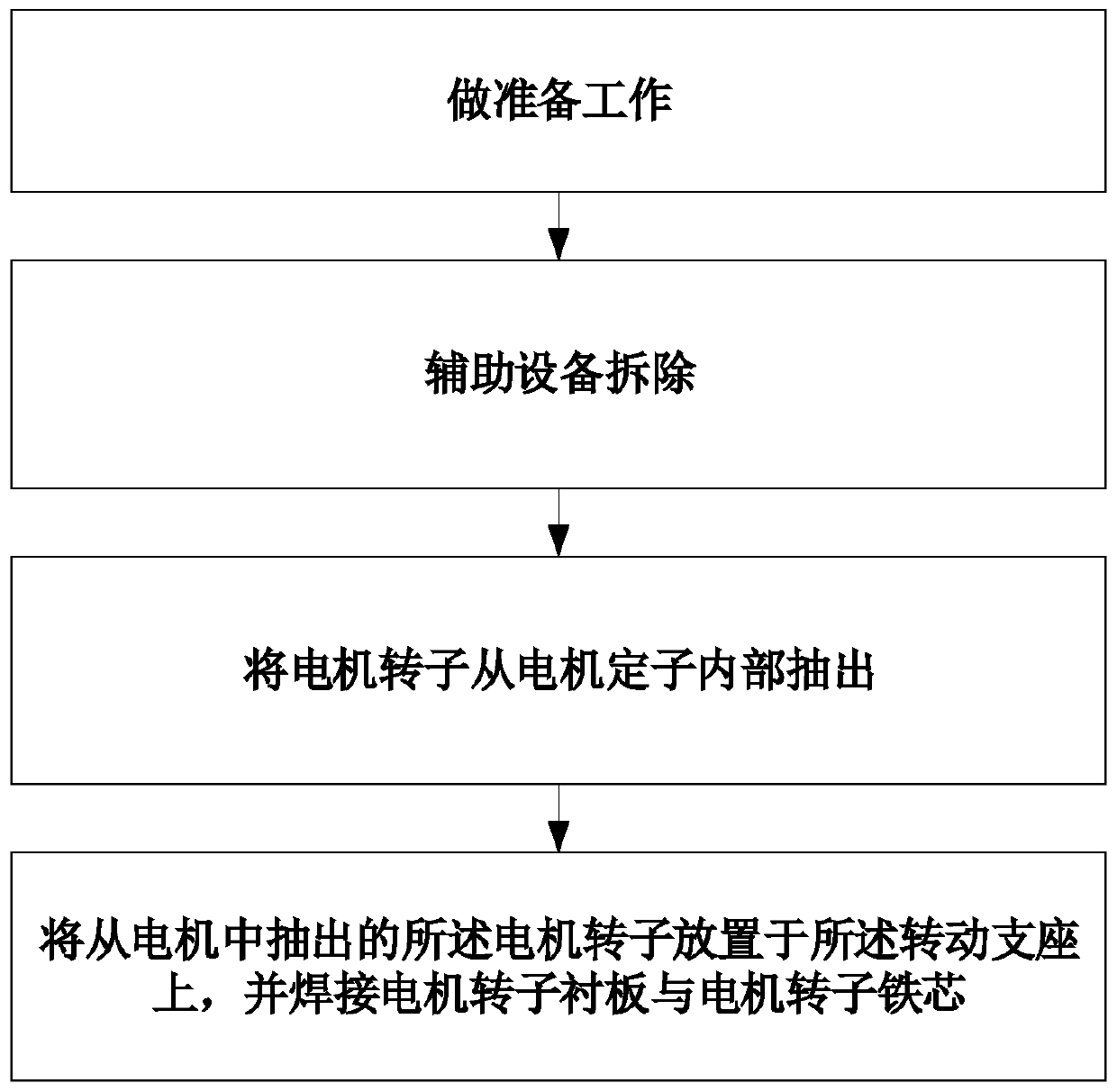

[0028] Such as figure 1 As shown, in an embodiment of the present invention, a method for motor maintenance is provided, including:

[0029] (1) Preparatory work: including hoisting equipment in place, wherein the hoisting equipment includes cranes, pole beams and chain blocks;

[0030] (2) Auxiliary equipment removal: Remove the motor rotor coupling guard, coupling bolts, cooler, fan cover and fan, upper bearing bush, anchor bolts, motor power connector, motor winding, and bearing bush temperature measurement probe;

[0031] (3) Pull out the motor rotor from the inside of the motor stator;

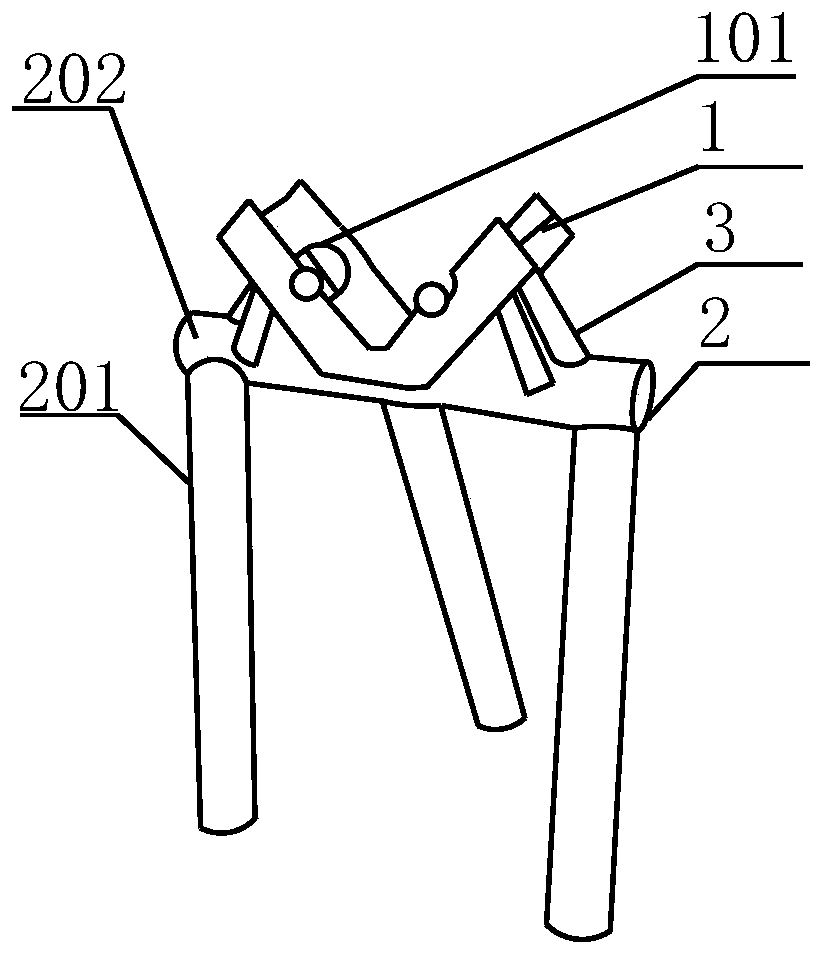

[0032] (4) Place the motor rotor extracted from the motor on the rotating support, and weld the motor rotor liner and the motor rotor iron core.

[0033] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com