A flexural piezoelectric composite material

A flexoelectric and composite material technology, applied in the direction of material selection for piezoelectric devices or electrostrictive devices, device material selection, etc., can solve complex structure, small apparent piezoelectric response, cumbersome preparation process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

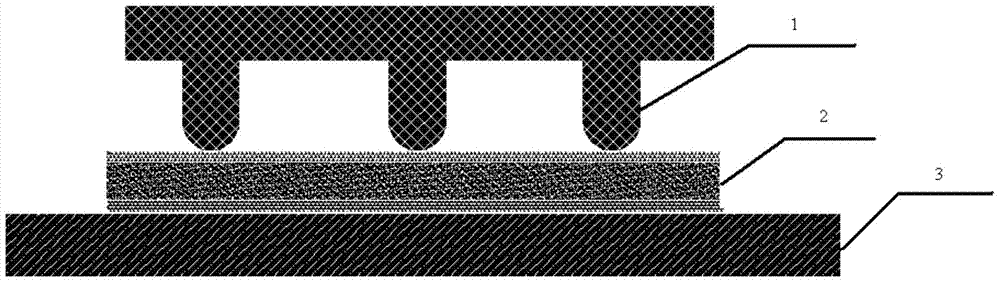

Image

Examples

Embodiment 1

[0032] Preparation of 0.92Na by traditional solid-phase synthesis 1 / 2 Bi 1 / 2 TiO3 -0.08BaTiO 3 Ceramics: a certain proportion of Bi 2 o 3 、Na 2 CO 3 、BaCO 3 、TiO 2 (Analytical grade, Sinopharm Group) was added into alcohol and ball milled for 6-8 hours, dried, and synthesized at 850°C for 2 hours. Then, ball mill the synthesized powder, add appropriate binder, and press it into a disc with a diameter of 25.4mm. After sintering at 1180-1200°C for 1 hour, a ceramic sheet with a diameter of about 20mm is obtained. The ceramic sheet is ground on both sides, and gold electrodes are plated on both surfaces by ion sputtering, and then placed on a flat substrate, and an external force is applied to the sample with a spherical indenter with a diameter of 6mm. ZJ-6A quasi-static d 33 Instrument measurement, the apparent piezoelectric properties of 2 ~ 3pC / N.

Embodiment 2

[0034] BaTiO prepared by traditional solid-phase synthesis 3 Ceramics, that is, a certain amount of BaCO according to the chemical formula 3 and TiO 2 (Analytical grade, Sinopharm Group) was mixed with alcohol ball milled for 6 hours, dried, and synthesized at 1200°C for 2 hours. Then the synthesized powder was ball-milled, added an appropriate binder, and pressed into a disc with a diameter of 25.4mm. After plastic discharge, it was kept at 1300°C for 2 hours and sintered to obtain a ceramic sheet with a diameter of about 21mm. Grind both sides of the ceramic sheet to a thickness of about 0.5mm, plate gold electrodes on both surfaces by ion sputtering, apply an external force to the sample with a spherical indenter with a diameter of 6mm, and use ZJ-6A quasi-static d 33 Instrument measurement, the apparent piezoelectric performance of 80 ~ 100pC / N.

Embodiment 3

[0036] Using the purchased soft-doped lead zirconate titanate ferroelectric ceramics (PZT-51) (Zibo Bailing Functional Ceramics Co., Ltd.), the ceramics were ground on both sides (diameter 25mm, thickness 0.5mm), and silver electrodes were prepared on both sides. On the flat substrate, use a spherical indenter with a diameter of 6mm to apply external force to the sample, and use ZJ-6A quasi-static d 33 Instrument measurement, the apparent piezoelectric properties of 10 ~ 50pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com