Bearing rolling needle holder

A cage and needle roller technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of long time, not in place, and difficulty in pressing needle rollers, and achieve the effect of convenient assembly and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

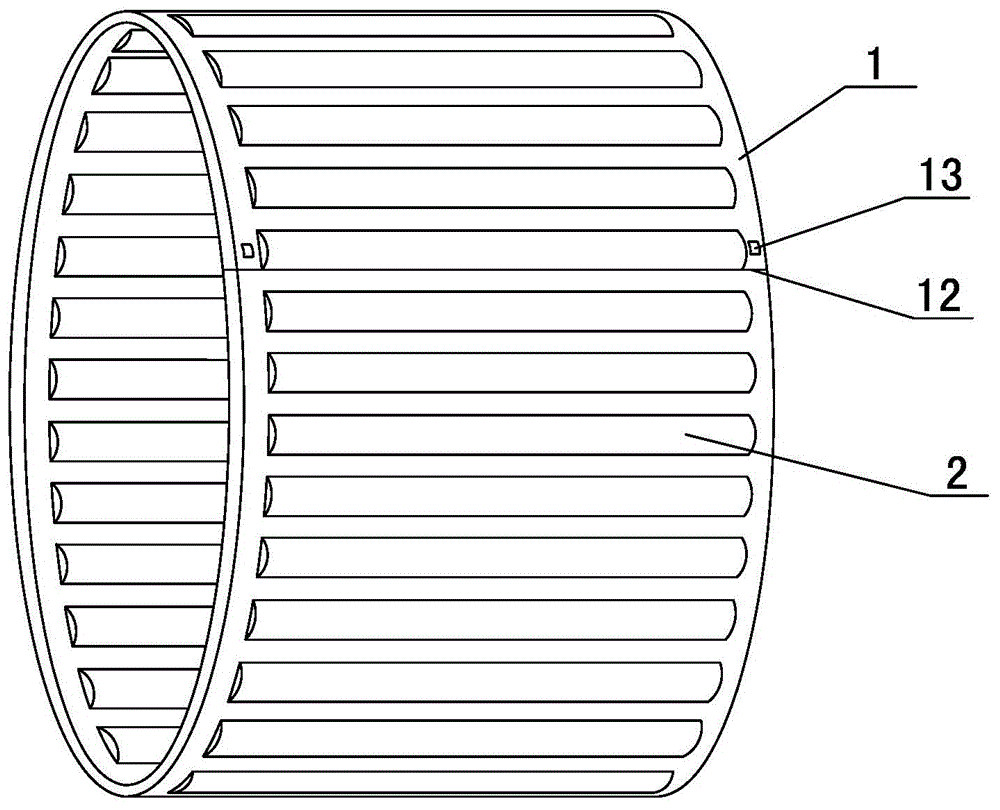

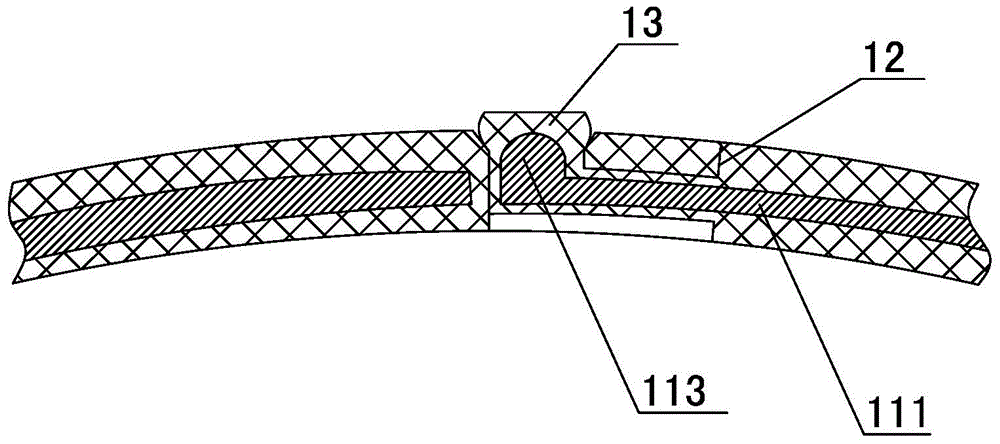

[0015] This preferred embodiment is figure 1 and 3 Shown is a bearing needle roller cage. The cage body 1 is composed of two connecting rings and a plurality of spacer strips arranged between the two connecting rings for isolating adjacent needle rollers 2. The cage body 1 is A disconnection part 12 is provided in the axial direction for opening the cage body 1, and one side of the disconnection part 12 is provided with a buckle 13 bayonet-connected with the other side. Wherein, the diameter of the head of the buckle 13 is larger than the diameter of the bayonet socket, and is pressed through during assembly.

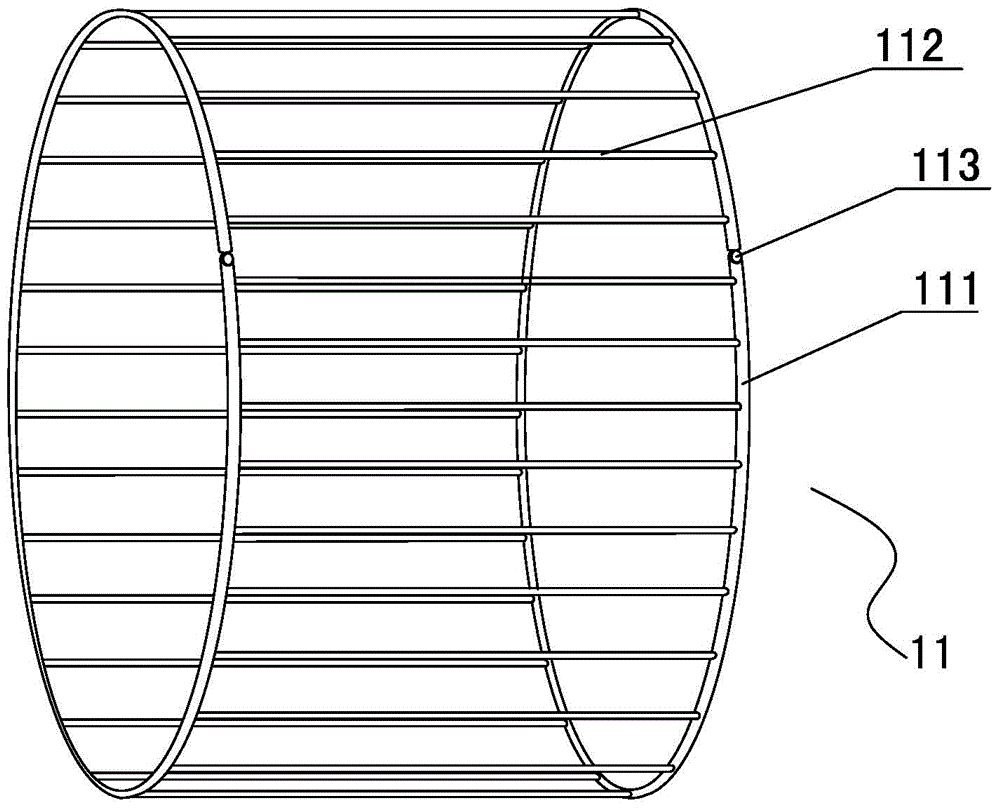

[0016] In this embodiment, the disconnection point 12 is arranged on the connecting ring, and may also be arranged on the connecting ring and the spacer bar at the same time. Cage body 1 consists of figure 2 The shown metal frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com