Inverted long-angle arc swirl anti-corrosion paddle and inverted long-angle arc swirl anti-corrosion stirring paddle

A technology of stirring paddles and paddles, which is applied in the direction of mixer accessories, dissolvers, mixers, etc., can solve the problems of long liquid mixing time, insufficient force of multi-flow columns, poor stirring effect, etc., and achieve wide flow rate, liquid swirl The effect of long flow rate and high mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

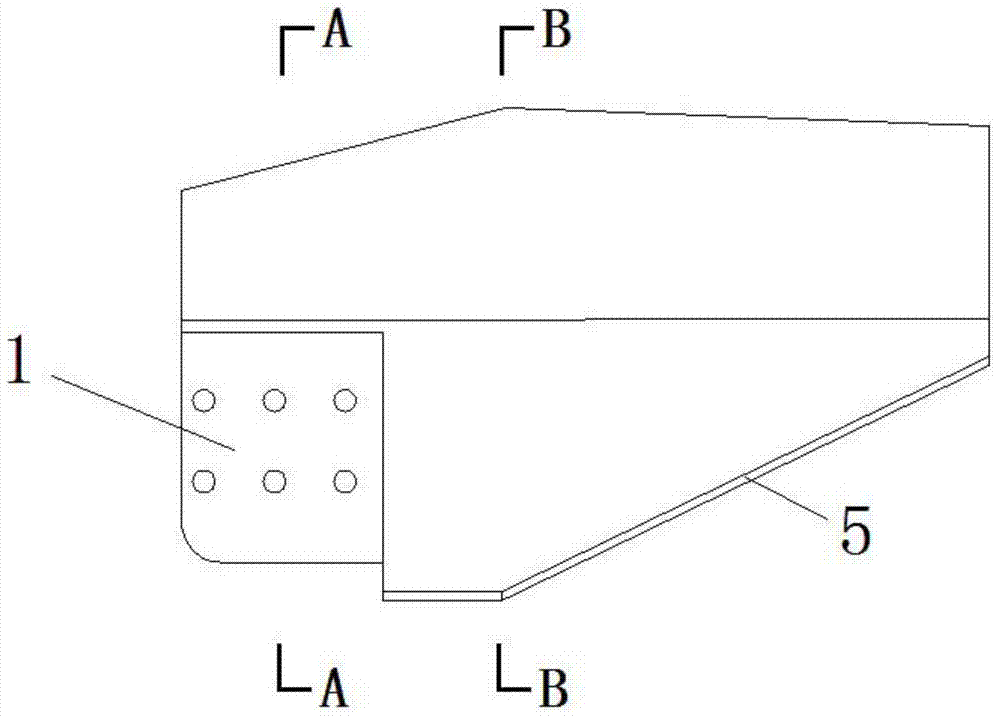

[0031] See Figure 1 to Figure 5 The inverted arc-shaped swirling anti-corrosion blade of this embodiment includes a steel frame 1 based on the shape of the blade and an anti-corrosion material formed by wrapping the steel frame (the steel frame 1 and the anti-corrosion material are in the prior art and will not be omitted here To repeat), the blade is an arc blade with convex and concave arc surfaces on the upper and lower sides respectively, and one side ( figure 1 The middle is the lower side, figure 2 The middle is the upper side) is composed of two angular lines of similar length, and the other side ( figure 1 The middle is the upper side, figure 2 The middle is the lower side) is composed of a long and one short angle line. It can be seen from the figure that the upper convex surfaces of the two sides of the arc-shaped blade are chamfered angle 2 and chamfered angle 3. The chamfered angle 2 and chamfered angle 3 respectively form the paddle with the lower side 4 and the l...

Embodiment 2

[0033] See Figure 6 to Figure 7 , The inverted arc-shaped swirling anticorrosive stirring blade of this embodiment includes a stirring shaft 6, a hub 7 and blades 8. As can be seen from the figure, the stirring blade of this embodiment is a single layer of three blades, and the blades of 8 The shape and features are the same as the blade described in Example 1. The steel frame 1 of the blade 8 is connected with the butt steel plate 9 of the hub by screws; the hub 7 is fixedly connected to the stirring shaft 6, the butt steel plate 9 is embedded in the milling groove of the hub 7 and welded and fixed; the butt steel plate 9 is welded and fixed under reinforcement Steel plate (not shown in the picture). From Image 6 It can be seen that the arc blade 8 is installed on the hub 7 of the stirring shaft 6 obliquely. Looking towards the direction of the stirring shaft 6, the upper liquid level is on the left, the lower liquid level is on the right, the upper liquid level is on the up...

Embodiment 3

[0037] See Figure 8 The stirring blade in this embodiment is a double-layer six-bladed blade, and the shapes and characteristics of the blade 8, the hub 7 and the stirring shaft 6 are the same as those in the second embodiment.

[0038] The stirring paddle of this embodiment is suitable for the stirring of 120 cubic to 800 cubic compound tanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com