A trolley capable of reducing waist labor intensity and its application method

A labor-intensive, trolley technology, applied in the field of trolleys, can solve problems such as high cost, inability to adapt to objects with various weight ranges, complex structure, etc., achieve low energy consumption, reduce waist labor intensity, and reduce bending times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

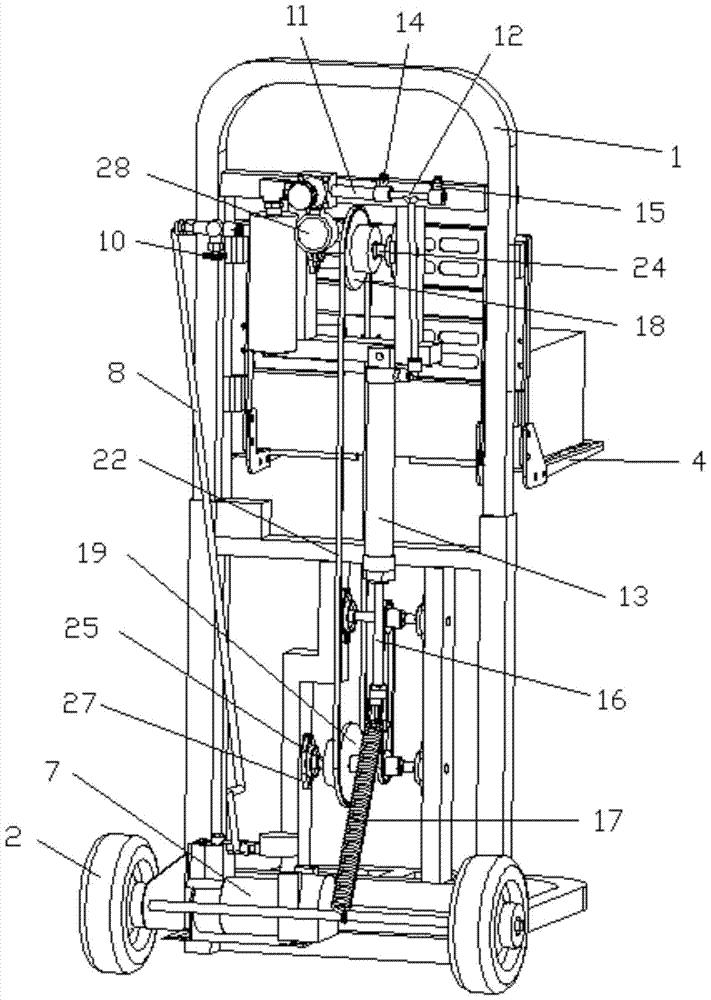

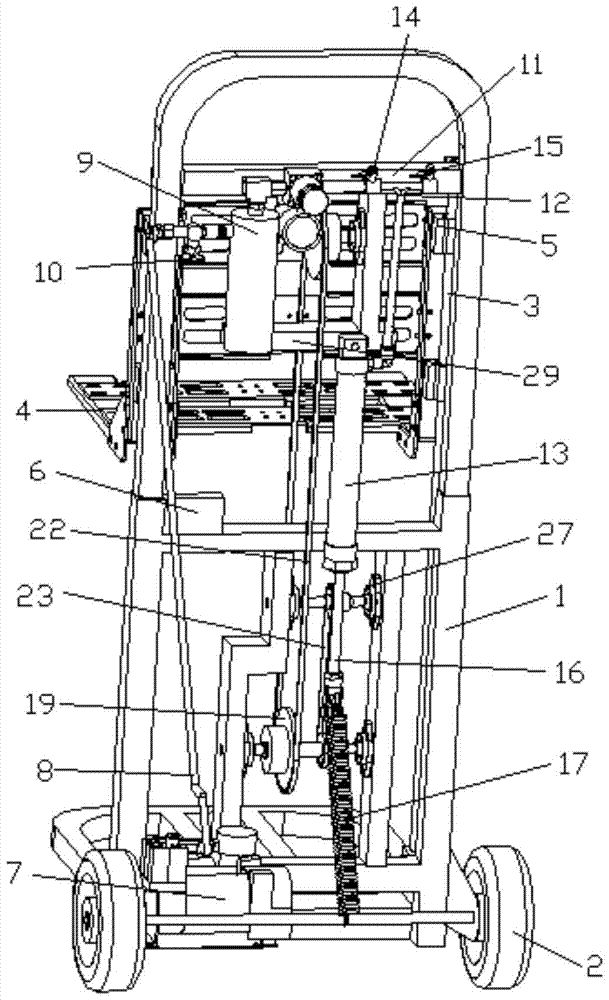

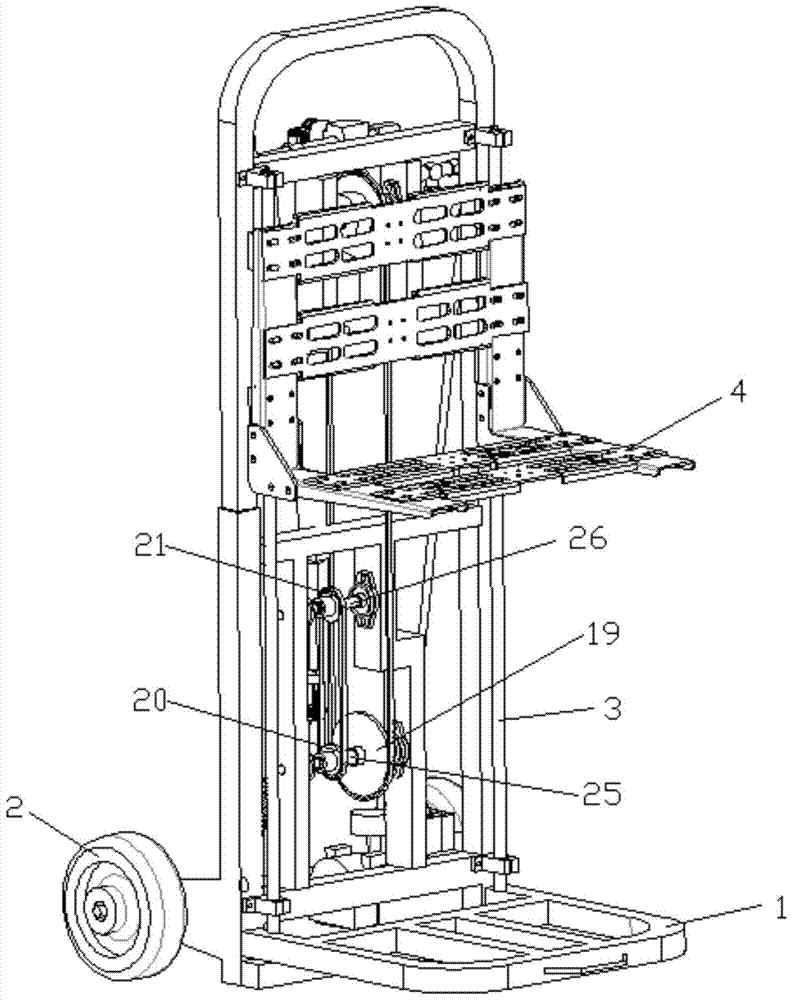

[0030] The present invention will be described in further detail below in conjunction with embodiment.

[0031] according to Figure 1 ~ Figure 3 As shown, a trolley that can reduce the labor intensity of the waist includes a vehicle frame 1, the bottom of the vehicle frame 1 is provided with rollers 2, guide rails 3 are provided on both sides of the vehicle frame 1, and the loading platform 4 is slidably connected to the vehicle through four sliders 5. On the guide rail 3, the frame 1 is provided with a pumping system. By controlling the amount of gas pumped into the gas storage tank and the cylinder by the pumping system, the initial gas compression ratio in the cylinder is changed, so as to adapt to the descent and lifting of goods of different qualities. The object can be damped down and automatically picked up. The pump air system includes a power supply device fixed on the frame 1. An air pump 7 is fixed on the lower end of the frame 1. The air pump 7 is powered by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com