Coordinated control method for power of wind power plant and system employing coordinated control method

A collaborative control, wind farm technology, applied in wind power generation, single-grid parallel feeding arrangement, etc., can solve the problem of inability to utilize wind resources, without considering the cost of unit maintenance, repair, and frequent replacement of spare parts, increasing the cost of human resources, etc. , to reduce the cost of human and material resources, reduce the cost of human resources, efficient operation and maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A wind farm power coordinated control method, including the following steps:

[0026] According to the geographical location of the wind turbines in the wind farm, the wind turbines in the wind farm are divided into m groups, and the order from the upwind direction to the downwind direction is recorded as the first 1, 2, 3,..., m groups. Each group contains The number of wind turbines is O j , The total number of wind turbines in the wind farm The power of the whole field is Where α j Is the power generation coefficient of the j-th generator, P k Is the output power of the k-th typhoon motor, The ρ is the air density, a is the axial induction factor, A is the swept area of the wind turbine, and v k Indicates the wind speed at the location of the k-th typhoon motor;

[0027] Obtain a set of α corresponding to the maximum P by the optimization method j ;

[0028] Will α j P k Implement control as the power limit of each wind motor.

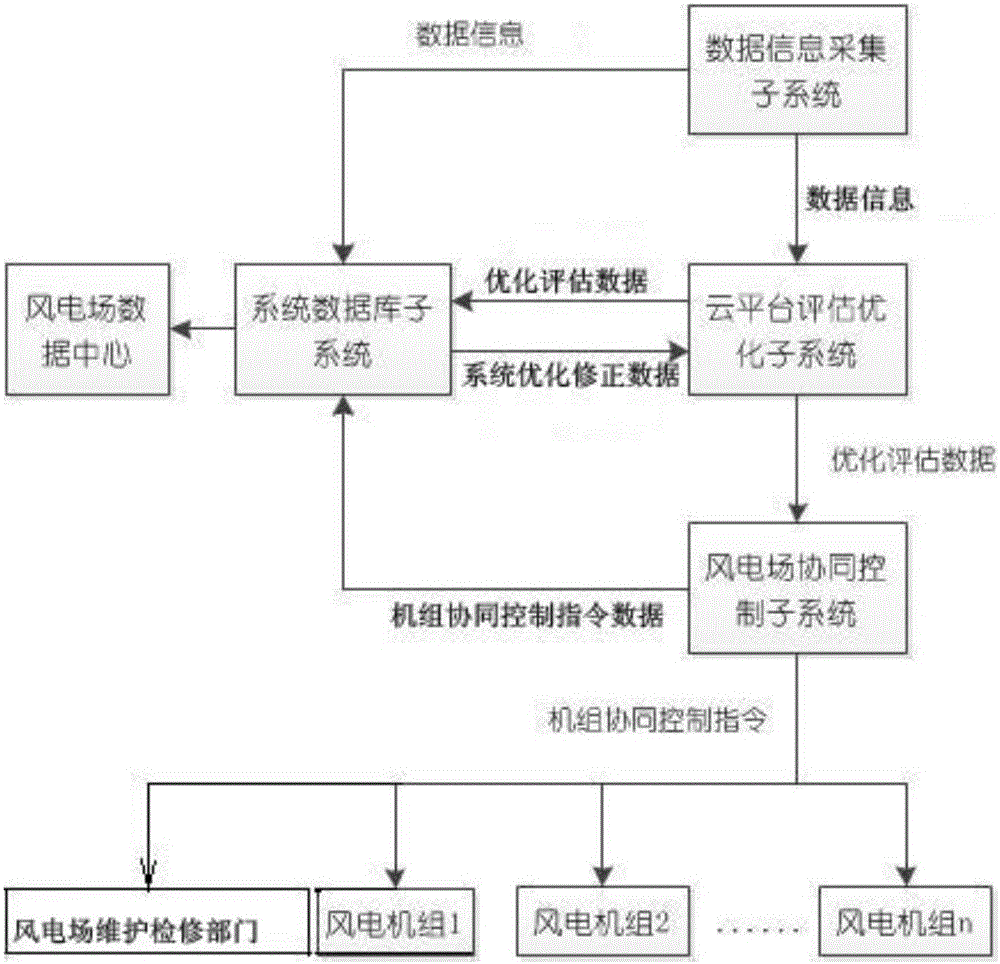

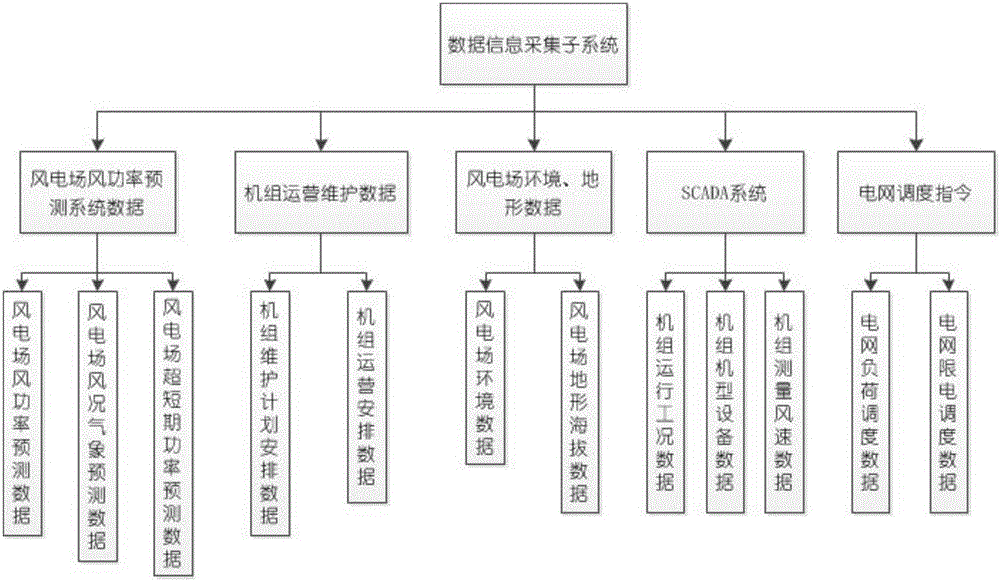

[0029] A wind farm power cooperative cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com