High precision automatic weighing conveying device

A technology for automatic weighing and conveying equipment, applied in the direction of weighing, measuring devices, instruments, etc., can solve problems such as vibration, affecting weighing accuracy, and large weighing errors, so as to reduce natural frequency, increase self-weight, weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

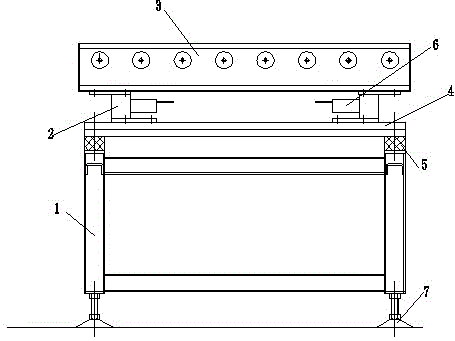

[0014] In the present invention, a counterweight plate 4 is provided between the load cell 2 and the bracket 1. The counterweight plate 4 can be in one form or assembled from several pieces. The present invention preferably selects the assembled form to reduce the weight of a single counterweight. Plate 4 quality facilitates installation.

[0015] Simultaneously the present invention establishes buffer 5 at counterweight plate 4 bottoms.

[0016] In the present invention, a counterweight plate 4 can also be provided in the space formed between the load cell 2 and the counterweight plate 4 to make full use of the existing space, that is, to increase the weight without increasing the space occupied by the equipment. Purpose.

[0017] The present invention uses the electric drum 6 to drive the conveyor belt 1 , and the electric drum 6 is arranged on the top of the load cell 2 .

[0018] The present invention arranges foot cup 7 at the lower part of support 5, and foot cup 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com