Blade, wind driven generator and blade manufacturing method

A blade and blade leading edge technology, applied in the field of wind power generation equipment, can solve problems such as poor aerodynamic performance of blades, and achieve the effect of improving aerodynamic performance of blades and solving the reduction of aerodynamic performance of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

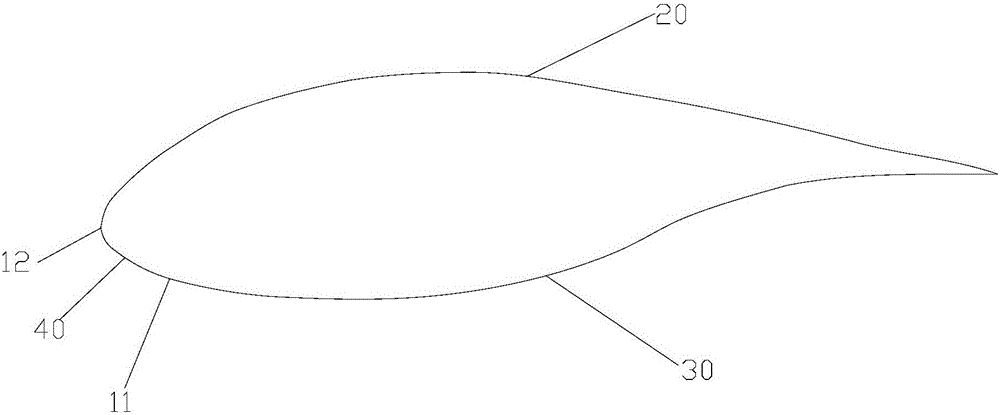

[0032] The blade, blade manufacturing method and wind power generator according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In this embodiment, the first shell and the second shell refer to two parts constituting the blade.

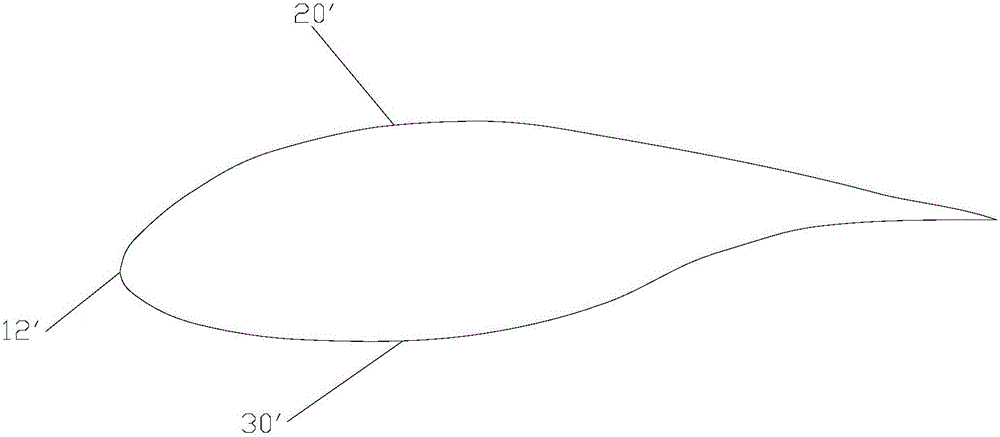

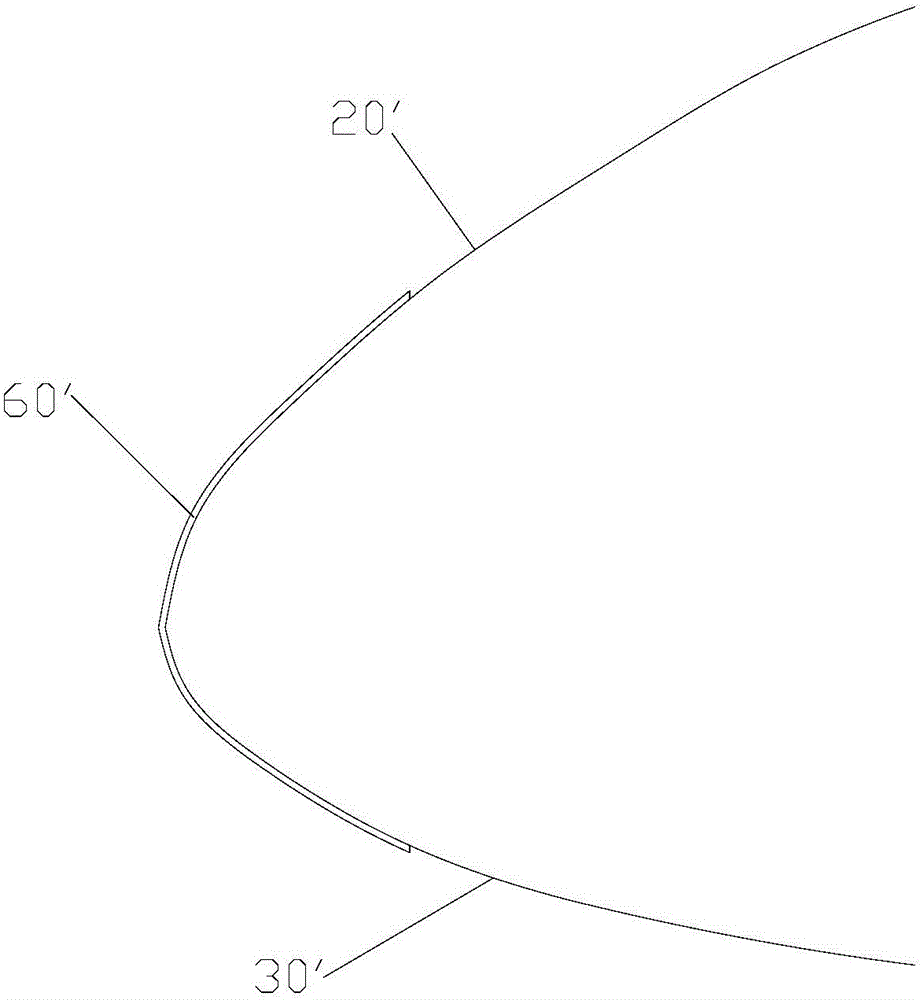

[0033] Such as image 3 As shown, according to the embodiment of the present invention, the blade has a first shell 20 and a second shell 30, and the junction of the first shell 20 and the second shell 30 forms a dividing line 11, along the length direction of the blade, At least a part of the parting line 11 is located on one side of the leading edge 40 of the blade. Since at least a part of the dividing line 11 is located on one side of the blade leading edge 40 (either the suction side or the pressure side), at least a part of the blade leading edge 40 is not divided by the dividing line 11 and is a complete In this way, the problem of unevenness of the leading edge 40 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com