Hydraulic self-locking quick installation blowout preventer and method

A blowout prevention device and hydraulic technology, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as environmental hazards, easy personal casualties, high labor intensity, etc., and achieve positioning guidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

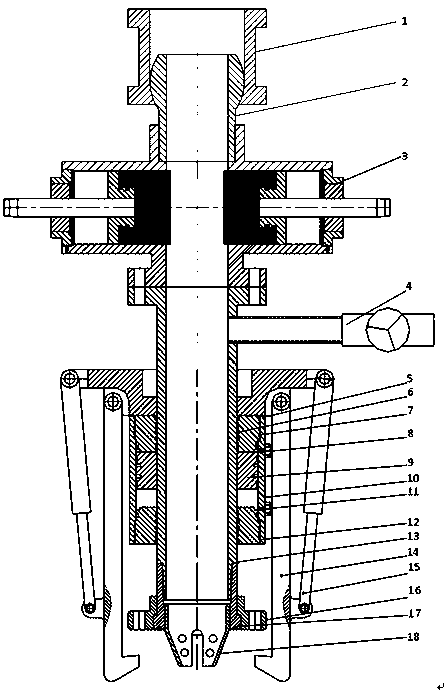

[0024] like figure 1 As shown, the hydraulic self-locking quick installation blowout preventer includes a blowout preventer assembly 3, a center pipe 13, and a blowout pipe 4. The lower end of the blowout preventer assembly is connected to the center pipe, and a blowout pipe is branched from the center pipe , the lower end of the central pipe is connected to an upper flange 16, which is matched with the lower flange of the wellhead, and also includes a space rotation fine-tuning control mechanism and a hydraulic automatic locking mechanism. The upper end of the blowout preventer assembly It is connected with the space rotation fine-tuning control mechanism, and a hydraulic automatic locking mechanism is sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com