Prefabricating and mounting method for pebble-pattern prefabricated slab

An installation method and prefabricated board technology, applied in the field of garden engineering, can solve the problems of difficulty in ensuring the fineness and quality stability of pebble pattern paving, the difficulty of welding and laying out the pattern texture, and the difficulty in guaranteeing the accuracy of the pattern, etc. The effect of reducing prefabricated traces, stable paving quality, and speeding up on-site construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

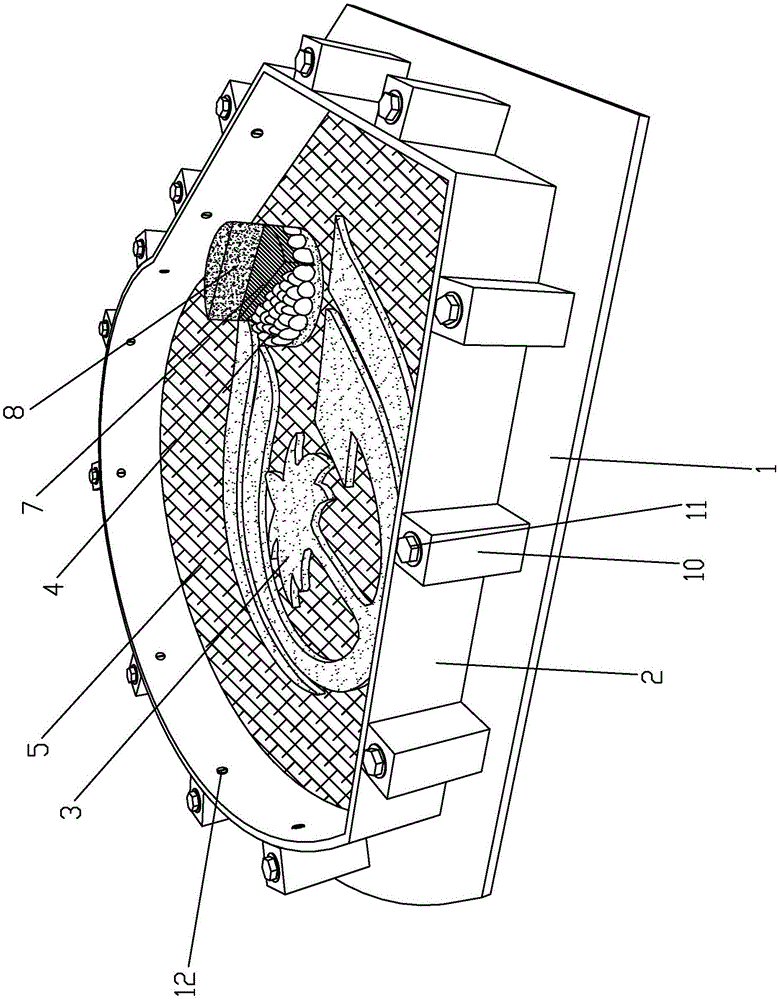

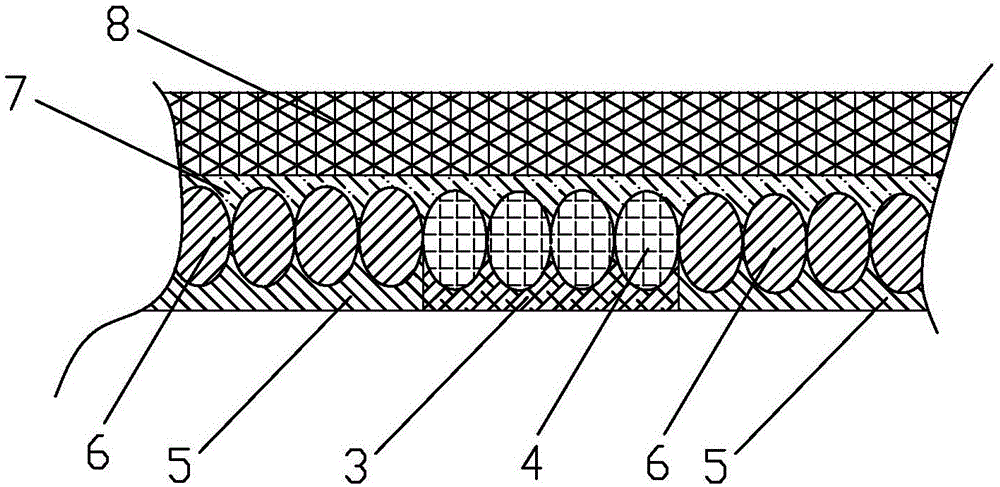

[0049] The present invention will be further described below in conjunction with accompanying drawing:

[0050] A method for prefabricating and installing a pebble pattern prefabricated panel, characterized in that it includes the following steps:

[0051] A: Pebble pattern prefabricated panel 99 prefabrication:

[0052] A1: Make the bottom plate 1 and the prefabricated frame 2 according to the shape of the pebble pattern to be laid, and the area enclosed by the prefabricated frame 2 is not more than 1m 2 , which can ensure that the weight of the formed pebble pattern prefabricated panel 99 is controlled below 100kg, and two workers can lift it up, and the larger pebble pattern can be divided into multiple pieces less than 1m 2 The pebble pattern prefabricated board 99 is prefabricated. When the pebble pattern is paved, the small pebble pattern prefabricated boards 99 can be spliced together. The shape of the prefabricated frame 1 can be set according to the pattern texture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com