Automatic straightener

An automatic adjustment and straightening technology, applied in the field of automation equipment, can solve the problem of wasting wire and other problems, and achieve the effect of saving time, smooth incision and high cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

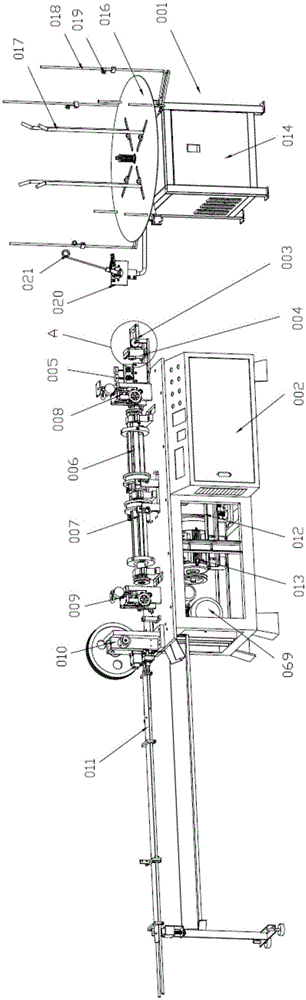

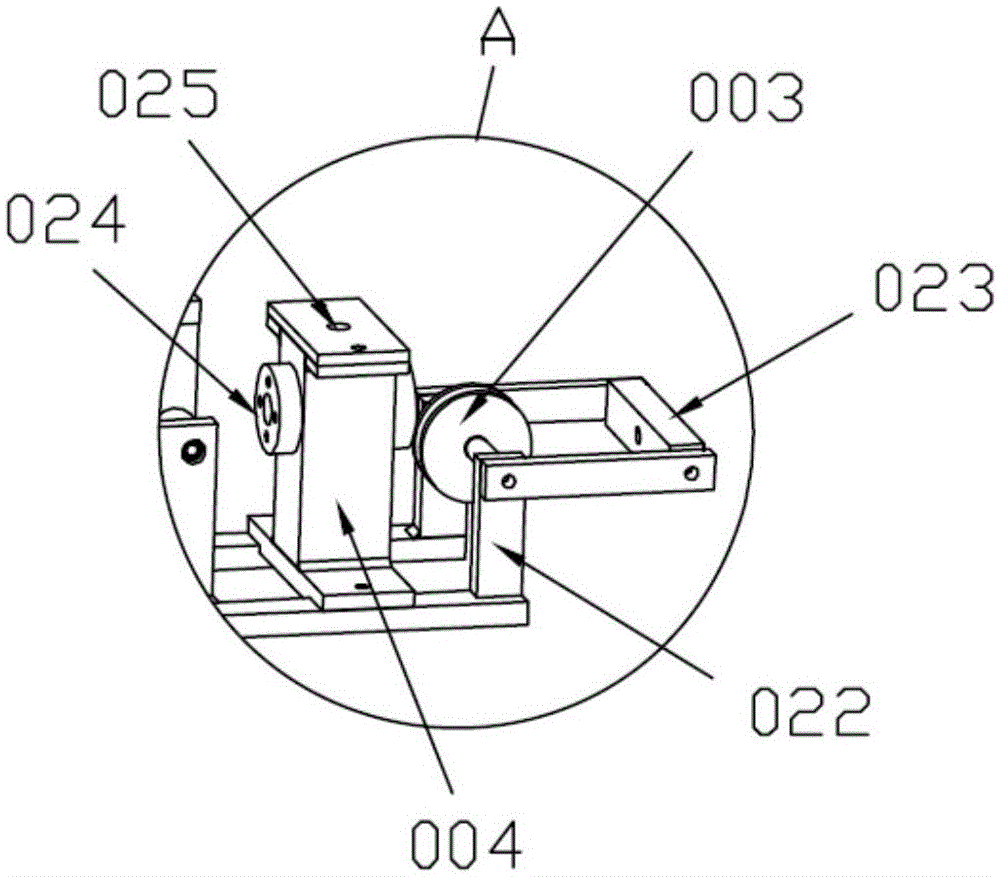

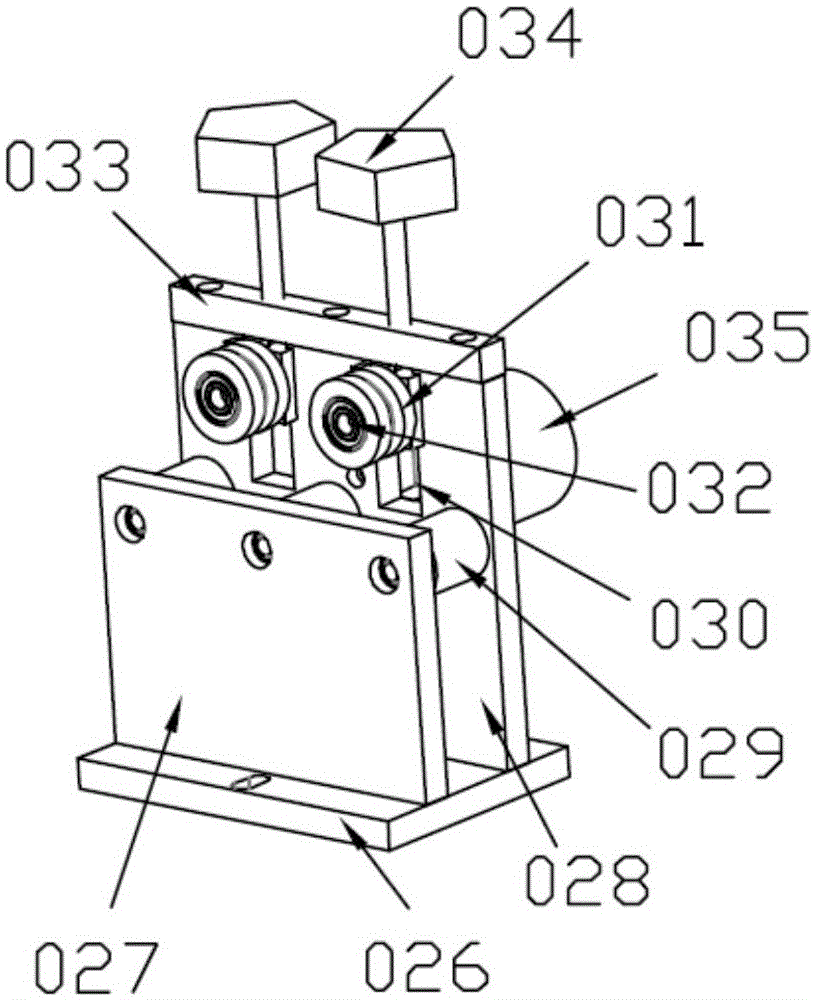

[0029] Figure 1 to Figure 6 An automatic straightening machine according to the present invention is schematically shown.

[0030] For an automatic straightening machine provided in this embodiment, please refer to figure 1 , including: an automatic feeding wire frame 001 and a main base 002, a wire introduction wheel 003, an oil pot 004 and an encoding mechanism 005 are arranged in turn on the side adjacent to the main base 002 and the automatic feeding wire rack 001, and the The middle part of the main base 002 is provided with a first straightening roller 006 and a second straightening roller 007 which are connected end to end, and a first line pressing mechanism 008 is arranged between the encoder base and the first straightening roller 006. The tail end of the second straightening cylinder 007 is connected with a second crimping mechanism 009, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com