A dust-proof medical ozone disinfection cabinet device

A disinfection cabinet, ozone technology, applied in the field of medical devices, can solve the problems that are not easy to overcome or correct immediately, the airflow channel is not easy to find, and the airflow channel is blocked, so as to achieve a stable and reliable device structure, balance unevenness, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

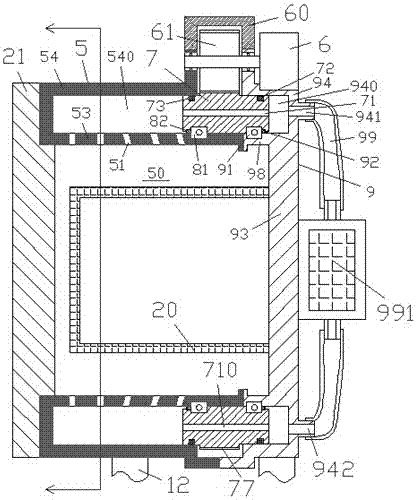

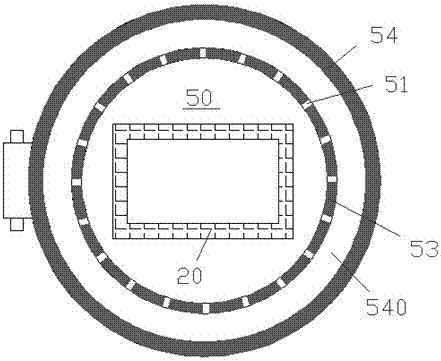

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] The dust-proof medical ozone disinfection cabinet device according to the embodiment includes an ozone gas flow ejection device 5, and the ozone gas flow ejection device 5 includes an annular inner layer part 53 with a cylindrical disinfection gas chamber 50 inside and an integrally formed surrounding The annular outer casing part 54 of the annular inner layer part 53 is provided with a multi-circle blowing air channel group distributed along the axial direction in the annular inner layer part 53, and there are multiple rings of blowing air channel groups uniformly distributed in the circumferential direction in each ring of air channel group. A blowing air duct 51 in a radial direction is used to input the airflow along the radial direction of the cylindrical sterile air chamber 50, and an annular airflow distribution is formed between the annular shell part 54 and the annular inner l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com