Polylactic acid composition, and production method and production apparatus of the same

A manufacturing method and polylactic acid technology are applied in the field of polylactic acid composition to achieve the effect of high molecular weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

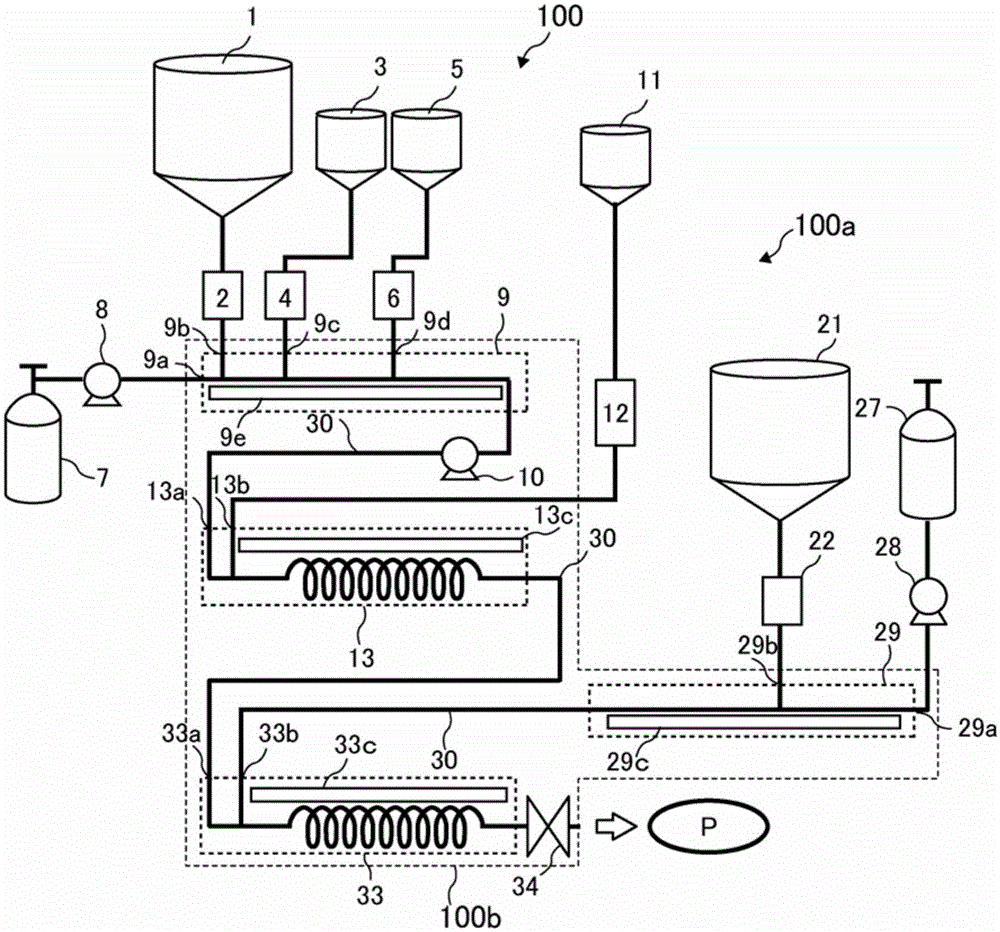

[0218] pass image 3 The polymerization reactor 100 performs ring-opening polymerization of L-lactide. The configuration of the polymerization reactor 100 is as follows.

[0219] (1) Tank 1 and metering feeder 2 (piston pump NP-S462, product of Nihon Seimitsu Kagaku Co., Ltd.):

[0220] Tank 1 was charged with a mixture of L-lactide (product of Purac, melting point: 100° C.) serving as a ring-opening polymerizable monomer and ethylene glycol (99:1 molar ratio) serving as a polymerization initiator. Note that in Tank 1, lactide is allowed to become liquid by heating it to a temperature equal to or higher than its melting point. To 100 parts by mass of lactide, 10 parts by mass of talc (SG-95, product of NIPPONTALC Co., Ltd.) serving as a nucleating agent was added.

[0221] (2) Tank 3 and metering feeder 4: not used in this example.

[0222] (3) Tank 5 and metering pump 6: not used in this embodiment.

[0223] (4) Tank 7: A carbon dioxide gas cylinder (gas cylinder) was us...

Embodiment 2-9 and comparative example 1-5

[0259] The polylactic acid compositions of Examples 2-9 and Comparative Examples 1-5 were manufactured in the same manner as in Example 1, except that the types and amounts of nucleating agents and crystallization accelerators, and polymerization initiation were changed according to the following Tables 1 to 3. dose.

[0260] Properties of the obtained polylactic acid composition were evaluated in the same manner as in Example 1. The results are shown in Tables 1 to 3.

Embodiment 10

[0262] The polylactic acid composition of Example 10 was produced in the same manner as in Example 1, except that the type of catalyst was changed to DBU according to the following Table 2, and the temperature of the delivery path of the biaxial stirring device was set to be between the inlet and the outlet. Both were at 80°C, and the respective types of nucleating agent and crystallization accelerator and the amount of polymerization initiator were changed.

[0263] Properties of the resulting polylactic acid composition of Example 10 were evaluated in the same manner as in Example 1. The results are shown in Table 2.

[0264] Table 1

[0265]

[0266] Table 2

[0267]

[0268] table 3

[0269]

[0270] The materials described in Tables 1 to 3 will be specifically described.

[0271] *Talc: SG-95, a product of NIPPONTALC Co.,Ltd.

[0272] *Kaolin: SATINTONE No.5, product of TAKEHARAKAGAKUKOGYO CO.,LTD.

[0273] * Phosphate ester metal salt compound: ADEKASTABNA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com