A kind of non-excavation polypropylene cable protection pipe and preparation method thereof

A cable protection, polypropylene technology, applied in the field of polypropylene cable protection pipeline and its preparation, can solve the problems of buckling instability, high cost, pipeline deformation, etc. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples serve to illustrate the invention without limiting the scope of protection set forth in the claims.

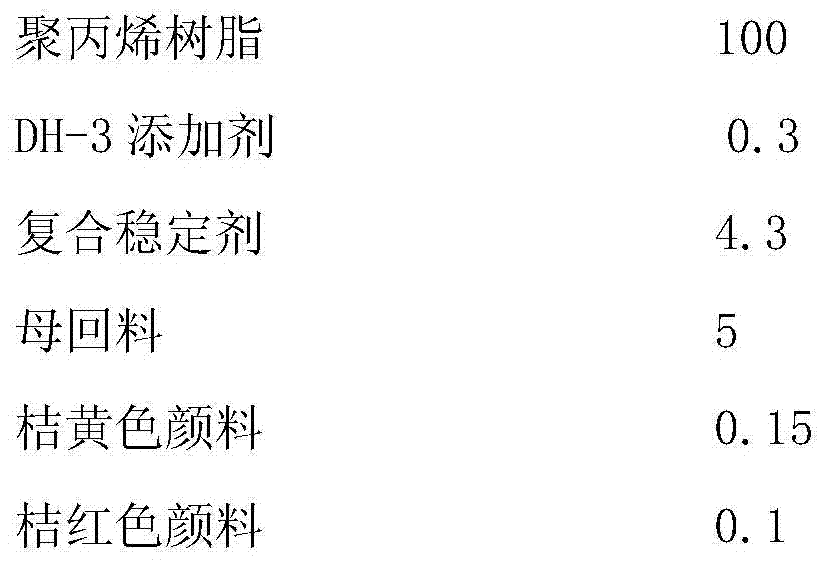

[0017] The formula of a kind of non-excavation polypropylene cable protection pipeline of the present invention is as follows:

[0018]

[0019] The above-mentioned DH-3 additive can be a product produced by Jiangsu Taicang Dahao Industrial Co., Ltd.; the main component of the above-mentioned composite stabilizer is dibutyltin modified acid, which can be a product produced by Hangzhou Rongshun Chemical Co., Ltd. Master recycled material refers to the material formed after crushing and granulating the brand-new unqualified products produced in the production process, and its performance is consistent with that of polypropylene resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com