Ginger straw pulverizing, collecting and briquetting device

A straw crushing and straw technology, which is applied in the field of ginger straw crushing, collecting and briquetting devices, can solve the problems of joint and intensive operations, and achieve the effects of eliminating damage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

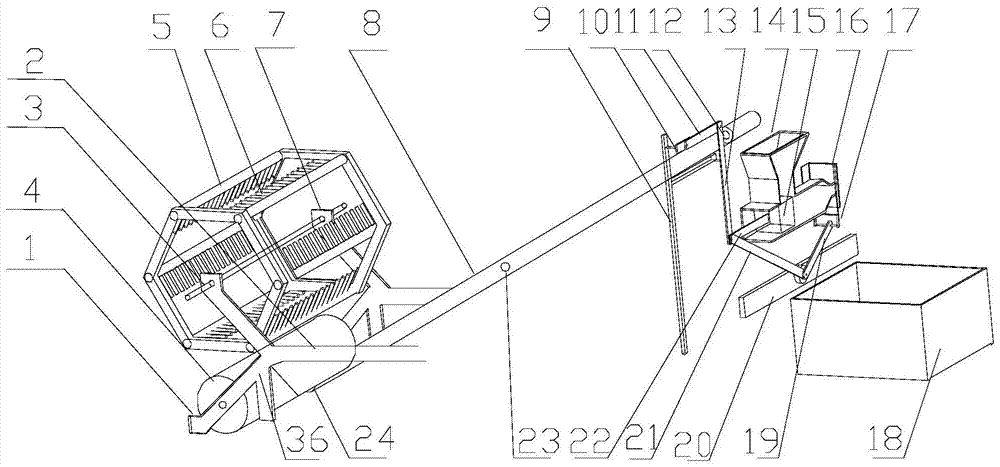

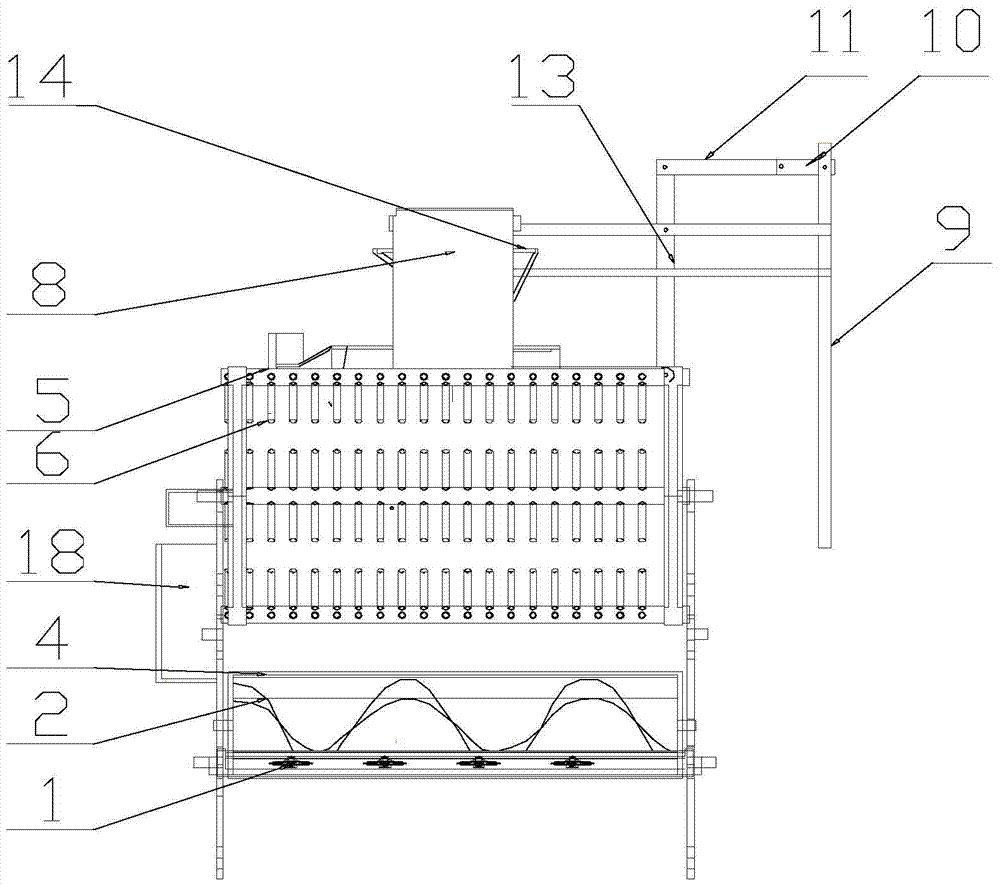

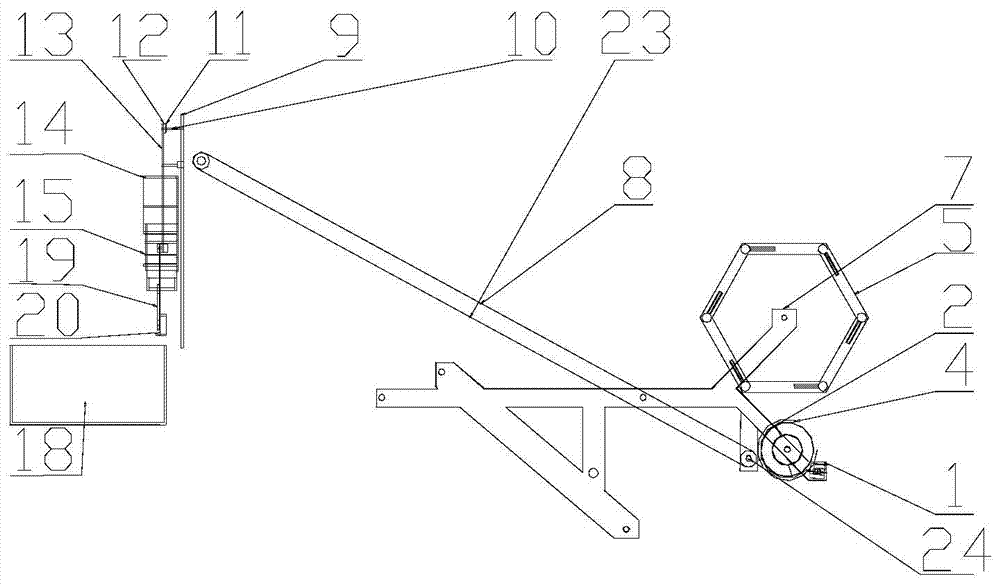

[0040] Such as Figure 1-Figure 3 As shown, the ginger straw crushing and collecting briquetting device includes a frame, a reeling device, a disc header device, an auger conveying device, a straw conveyor belt device, and a crank six-link briquetting device.

[0041] The reel support 7 fixes the reel through the reel main shaft 3, and at the same time, the reel support 7 belongs to a part of the frame 36, and the lower part of the reel support 7 is fixed with the auger conveyor 2 to support the straw The support of the conveyor belt support shaft and the support 1 of the round table cutter. Wherein the round table cutter support 1 is fixed with 4 round table cutter drive shafts 26, and each round table cutter drive shaft has a round table cutter 25. An auger conveyor 2 is fixed behind the round table cutter 25, and an auger conveyor shell 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com