A soft capsule testing machine

A detection machine and soft capsule technology, applied in sorting and other directions, can solve the problems that the feeding device is difficult to discharge uniformly and stably, the turntable is not easy to clean and clean, and cannot adapt to multiple varieties of capsules, etc. Efficiency stability, high-quality detection effect, and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

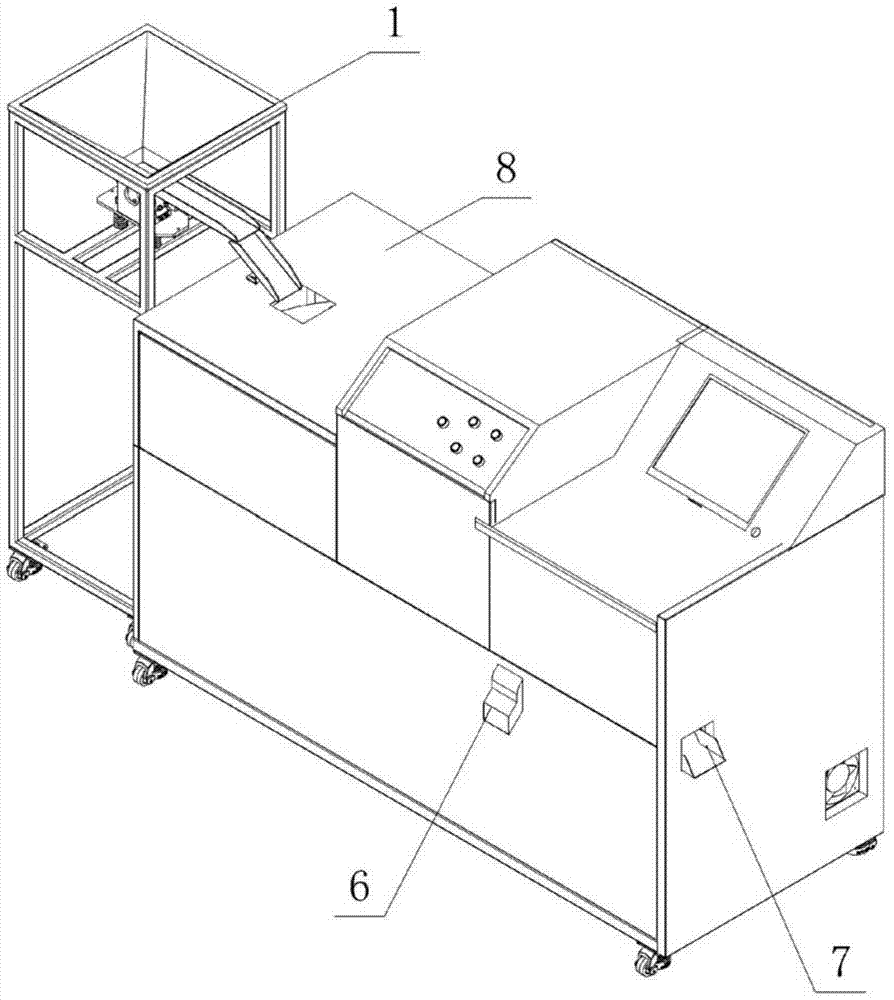

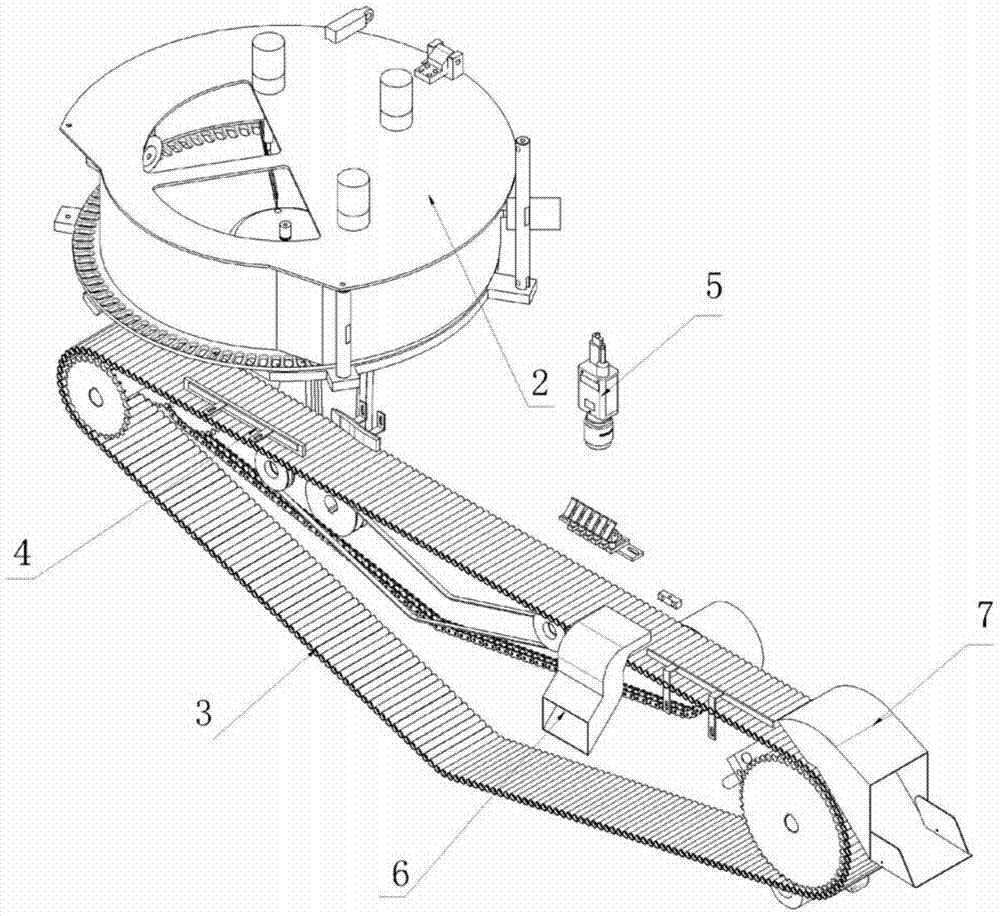

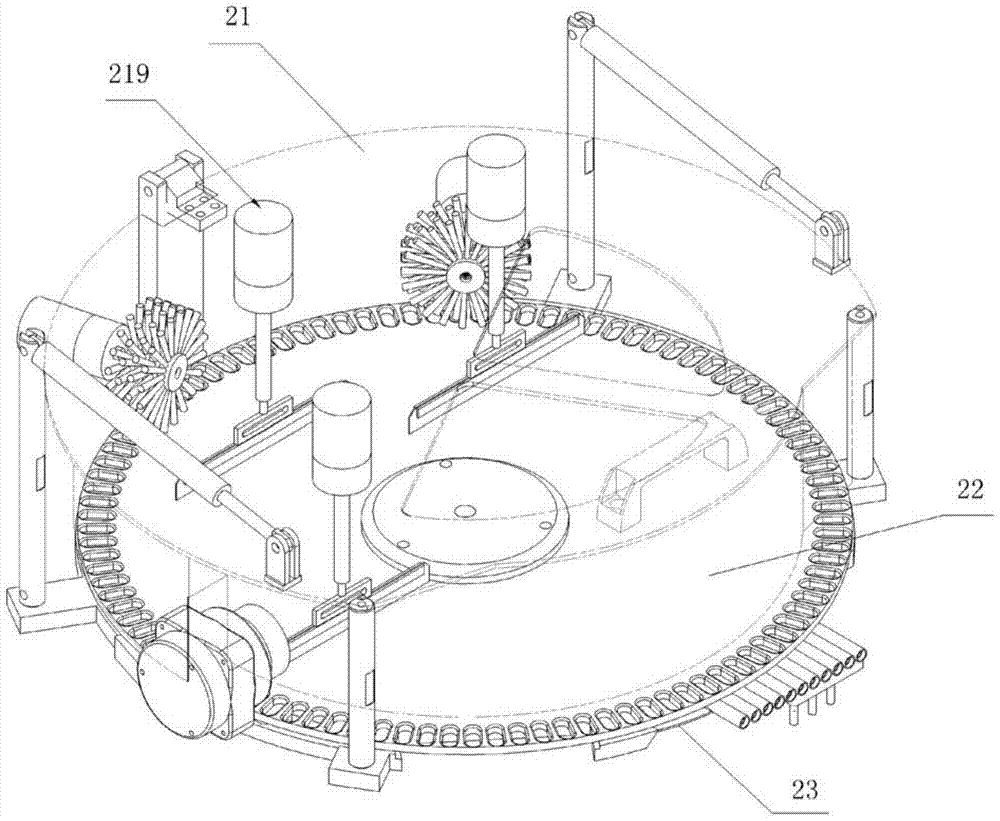

[0043] like Figure 1-2 As shown, a kind of soft capsule inspection machine of the present invention comprises a feeding device 1, a feeding device 2, a conveying device 3, a material blocking arrangement mechanism 4, a visual inspection device 5, a rejecting passage assembly 6, a finished product passage assembly 7 and Case 8.

[0044] The feeding device 1 includes a feeding funnel, a vibrator and a feeding guide rail.

[0045]The conveying device 3 is used to convey the capsules to the testing station. The conveying device 3 includes a chain, a sprocket and a conveyor belt for transmission. The conveyor belt is composed of a plurality of rollers, and the sprocket drives the conveyor belt to move. Sensors are arranged at the key nodes of the movement of the entire conveying device 3 to monitor the material feeding of the capsules in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com