Small soybean joint harvesting machine

A combined harvester and soybean technology, applied in the field of agricultural machinery, can solve the problems of high soybean cleaning rate and crushing rate, difficult to achieve profiling, uneven soybean stubble, etc., and achieve high harvesting productivity, high coordination and coordination, The effect of faster decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

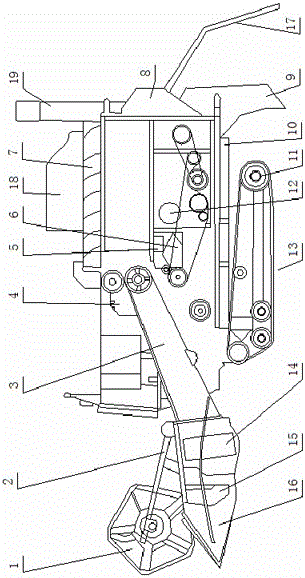

[0037] Specific examples: such as figure 1 As shown, the small-sized soybean combine harvester of the present invention includes a frame 10, a power unit assembly, a crawler walking device 13, a header assembly 16, a conveying bridge device 3, a threshing and cleaning assembly 5, a water tank 18 and straw Crushing device assembly 8;

[0038] Frame 10 is the fixed connection mechanism of power unit assembly, crawler belt traveling device 13, header assembly 16, conveying bridge device 3, threshing and cleaning assembly 5, water tank 18 and straw crushing device assembly 8.

[0039] Power plant assembly, including engine 4, transmission components, hydraulic devices and pipelines;

[0040] The crawler belt running device 13 is driven by a hydraulic device, and mainly includes driving wheels 11 installed on both sides of the bottom of the frame 10, driven wheels distributed between the two driving wheels 11 on the same side, auxiliary wheels 15, crawlers, and the two sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com