Automatic ironing machine

An ironing machine and automatic technology, applied in the field of ironing machines, can solve problems such as low work efficiency, high labor intensity, and increased burden, and achieve the effects of improving work efficiency, reducing labor intensity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

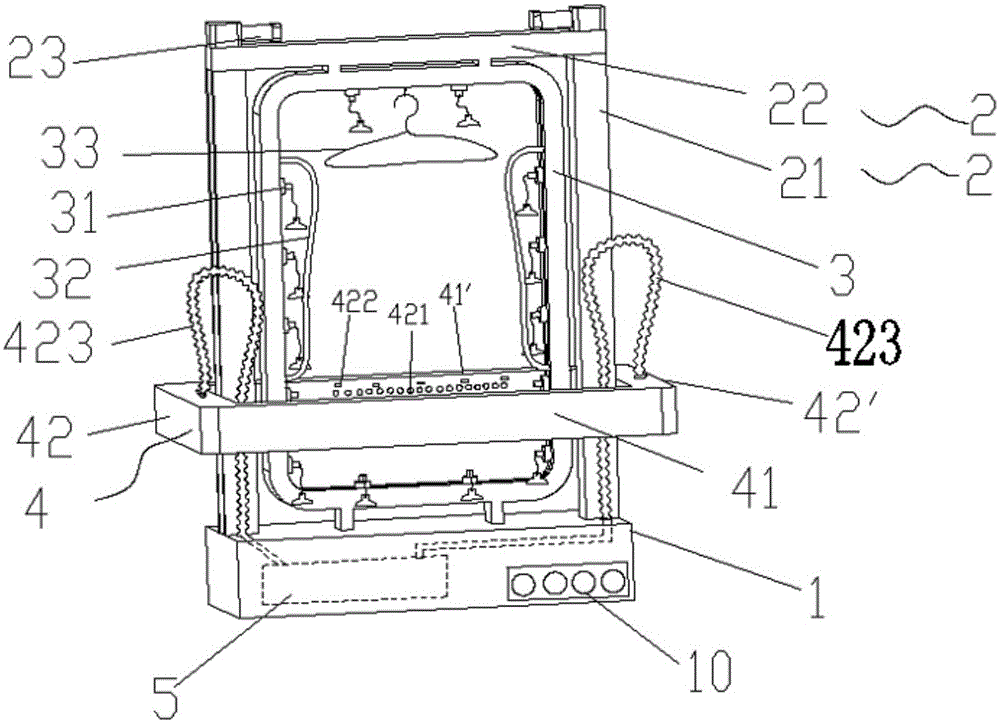

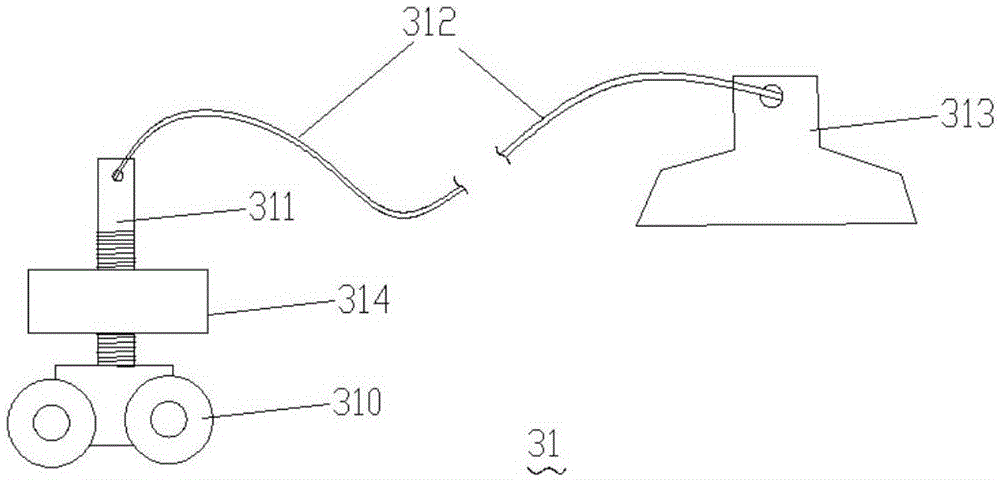

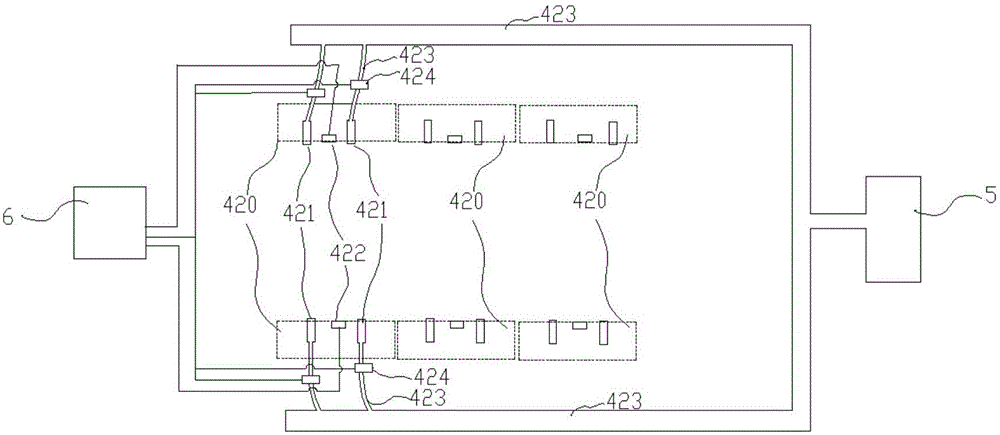

[0019] like Figure 1 to Figure 5 As shown, the structure of the present embodiment 1 and 2 is the same, but the types of objects to be ironed are different. The present embodiment 1 and 2 both include a bottom platform 1, a main frame 2 fixed to the bottom platform 1, and a main frame 2 fixed to the main frame 2. The closed chute 3 inside, the lifting air jet device 4 movably connected to the two sides of the main frame 2, the water tank 5 with heating elements installed in the base 1, and a controller 6 are also included. The main frame 2 includes a vertical The two left and right support arms 21 arranged vertically and the crossbeam 22 erected on the top of the left and right two support arms, the support arms 21 are steel frame members with a concave shape in cross section and openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com