Halogen-free flame-retardant high-strength ceramizable silicone rubber

A high-strength, silicone rubber technology, applied in the field of rubber materials, can solve the problems of ceramic silicone rubber flame retardancy, poor mechanical properties, and difficult practical requirements, and achieve high flame retardancy, high crust strength, and tensile strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of halogen-free flame-retardant high-strength porcelainable silicone rubber of the present invention, its raw material is prepared according to the composition of parts by weight, specifically as follows:

[0023] Weigh 100g of methyl vinyl silicone rubber, 15g of zinc borate, 20g of aluminum hydroxide treated by the aforementioned process, 14g of magnesium hydroxide, 8g of MCA-JN, 2g of MPOP, and 1g of antioxidant 1010 through the aforementioned process. These substances are prepared sequentially according to the steps of the above-mentioned preparation method, and then a halogen-free flame-retardant high-strength porcelain-able silicone rubber can be obtained.

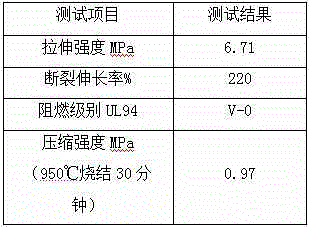

[0024] After the silicone rubber of the present invention is vulcanized at 170°C for 5 minutes, it is tested according to national standards, and the results are as follows:

[0025]

[0026] The ceramizable silicone rubber can form self-supporting ceramic objects when exposed to fire, ...

Embodiment 2

[0026] The ceramizable silicone rubber can form self-supporting ceramic objects when exposed to fire, and the higher the temperature and the longer the time, the better the ceramization effect. Embodiment 2, a halogen-free flame-retardant high-strength porcelainable silicone rubber of the present invention, its raw materials are prepared according to the composition of parts by weight, specifically as follows:

[0027] Weigh 100g of methyl vinyl silicone rubber, 20g of hydrotalcite, 10g of zinc borate, 5g of glass powder, 20g of MCA-JN, 4g of MPOP, and 1g of antioxidant 1330, and prepare the above-mentioned substances sequentially according to the steps of the above-mentioned preparation method, Halogen-free, flame-retardant and high-strength porcelain-able silicone rubber can be prepared.

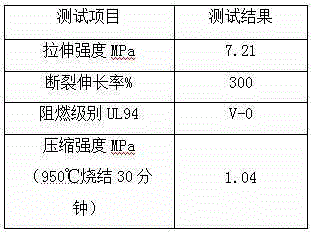

[0028] After the silicone rubber of the present invention was vulcanized at 170°C for 5 minutes, it was tested according to national standards, and the results were as follows:

[0029] ...

Embodiment 3

[0031] Embodiment 3, a kind of halogen-free flame-retardant high-strength porcelainable silicone rubber of the present invention, its raw materials are prepared according to the composition of parts by weight, specifically as follows:

[0032] Weigh 100g of methyl vinyl silicone rubber, 14g of aluminum hydroxide treated by the aforementioned process, 10g of zinc borate, 10g of light calcium carbonate, 5g of magnesium oxide, 20g of MCA-JN, and 1g of antioxidant 330. According to the steps of the above preparation method, the halogen-free, flame-retardant and high-strength porcelain-able silicone rubber can be prepared.

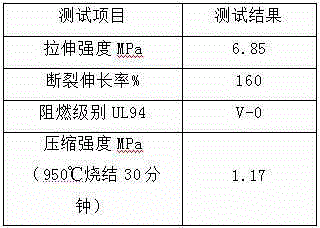

[0033] After the silicone rubber of the present invention was vulcanized at 170°C for 5 minutes, it was tested according to national standards, and the results were as follows:

[0034]

[0035] The ceramizable silicone rubber can form self-supporting ceramic objects when exposed to fire, and the higher the temperature and the longer the time, the better the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com