Vehicle gear shifting switching mechanism

A technology for converting mechanisms and vehicles, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of large structure size, poor adaptability, and many materials, so as to reduce the shifting operation force and optimize the The effect of shifting comfort and convenient rocker arm angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

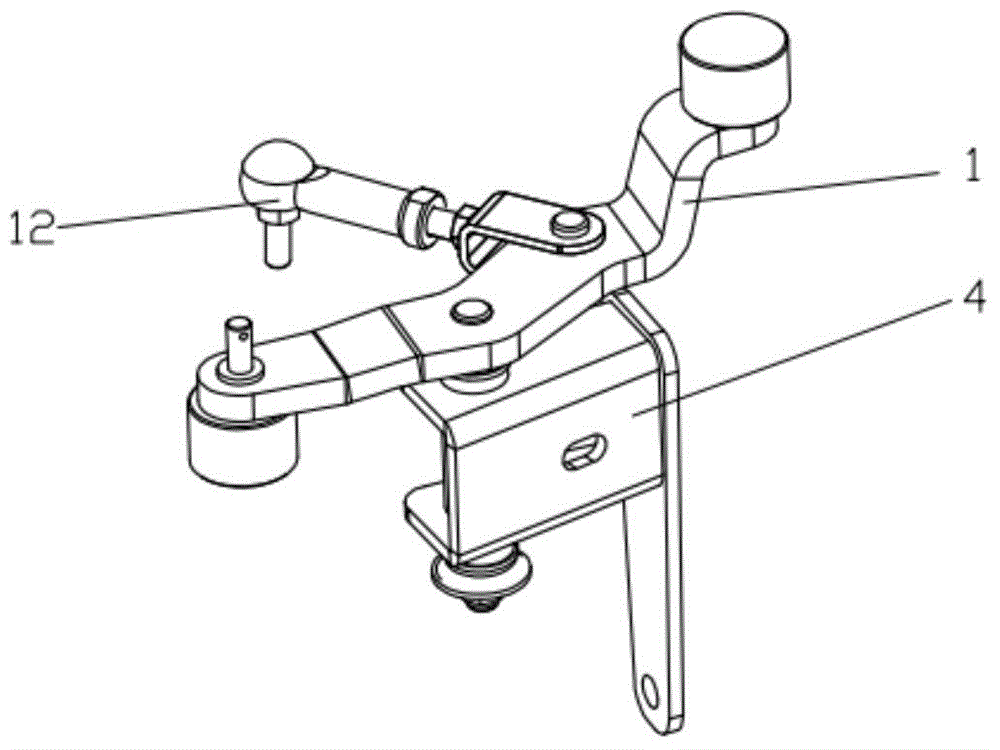

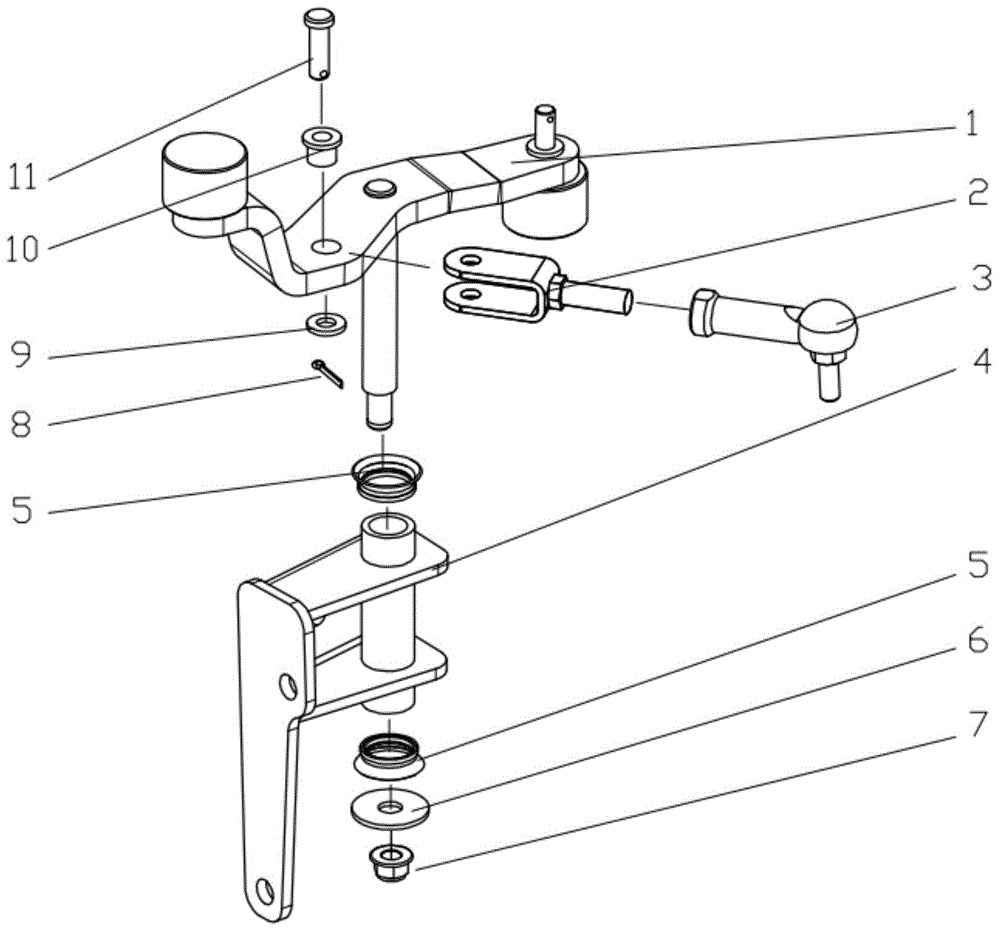

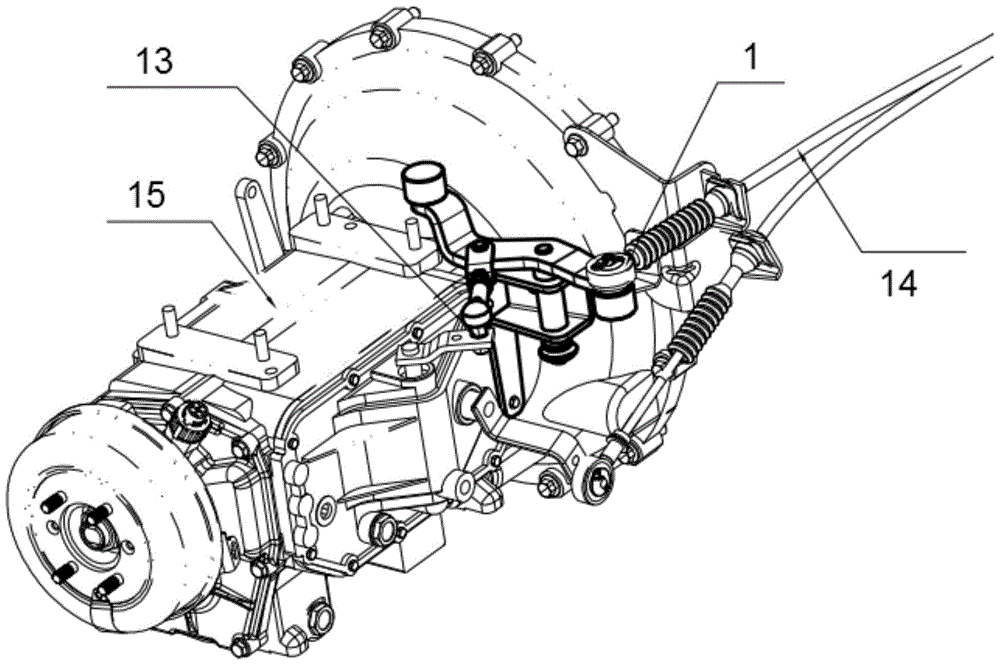

[0021] see figure 1 , a vehicle shift conversion mechanism, has:

[0022] The support 4 fixed on the vehicle;

[0023] The inertia hammer rocker arm 1 rotatably installed on the support 4 near the middle, wherein one end of the inertia hammer rocker arm 1 is connected with the shift cable 14;

[0024] An adjusting arm assembly 12 with one end hinged to the other end of the inertia hammer rocker arm 1 , wherein the other end of the adjusting arm assembly 12 is hinged to the shift rocker arm 13 .

[0025] The adjustment arm assembly 12 includes an adjustment fork 2 and a ball head 3; one end of the adjustment fork 2 is hinged with the inertia hammer rocker 1, and the other end is provided with an extension rod; one end of the ball head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com