A winding mandrel with a reversible half shaft and a fiber composite winding method

A technology of fiber composite materials and core molds, applied in the field of material science, can solve the problems of not meeting the requirements of biaxial winding and difficulty in process molding, and achieve the effect of reducing the workload and solving the large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

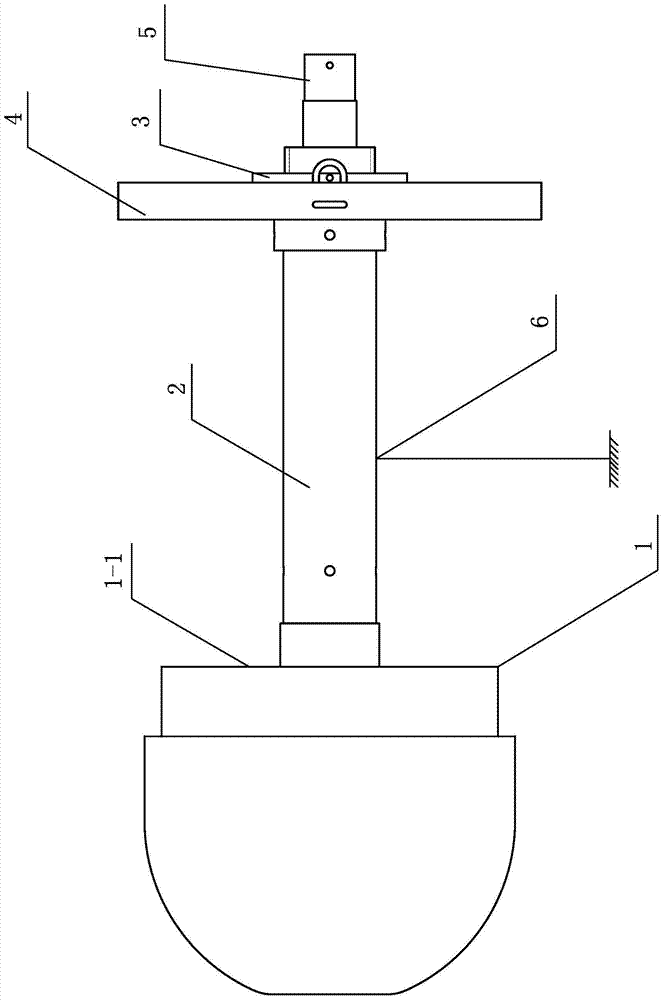

[0015] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a reversible half shaft winding mandrel described in this embodiment includes a mold main body 1, a main shaft 2, a counterweight plate mounting part 3, a counterweight plate 4 and a winding machine clamping and rotating connection shaft 5, and the mold The main body 1, the main shaft 2, the counterweight disc mounting part 3, and the winding machine clamping and rotating connecting shaft 5 are connected in sequence from left to right, and the counterweight disc 4 is set on the counterweight disc mounting part 3.

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 This embodiment will be described. A rotatable supporting point 6 is provided in the middle of the main shaft 2 of the reversible semi-shaft winding mandrel in this embodiment. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To describe this embodiment, the end face of the connection between the mold body 1 and the main shaft 2 of a reversible half-shaft winding mandrel described in this embodiment is a flat head 1-1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com