A CNC quilting machine

A quilting machine and sewing technology, which is applied to sewing machine components, sewing machines for sewing quilts, sewing equipment, etc. It can solve the problems of low working efficiency of quilting machines, non-adjustable length of quilt holders, and reduced labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

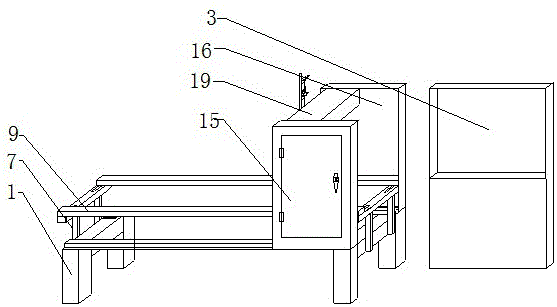

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

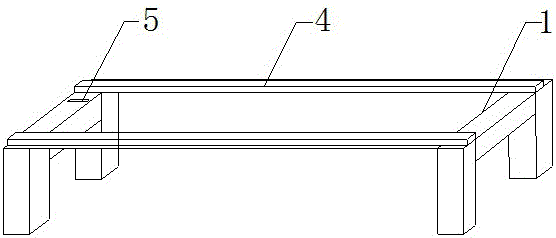

[0035] Such as figure 1 As shown, a numerically controlled quilting machine has rails 4 provided on the left and right sides of the upper side of the frame body 1 respectively, and the rails 4 provide a running track for the first driving box 15 and the second driving box 16, allowing them to move back and forth. The left and right sides of the front side of the upper side of the frame body 1 are respectively provided with rectangular slots A5, and the rectangular slots A15 can fix the transmission wheel A6 and fasten the transmission belt A14.

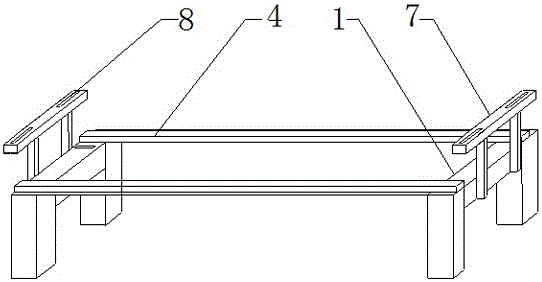

[0036] Such as Figure 2-4 As shown, the rectangular slotted holes A5 on the left and right sides of the front side of the frame body 1 are fixedly provided with transmission wheels A6, and the front and rear sides of the upper side of the frame body 1 are also provided with brackets 7 respectively. The left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com