Novel sterile filling valve

An aseptic filling and filling valve technology, which is applied in the field of beverage filling, can solve the problems of easy splashing, irregular liquid and non-concentration, and achieve the effect of avoiding splashing and reducing the generation of bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further explained below in conjunction with the drawings and specific embodiments.

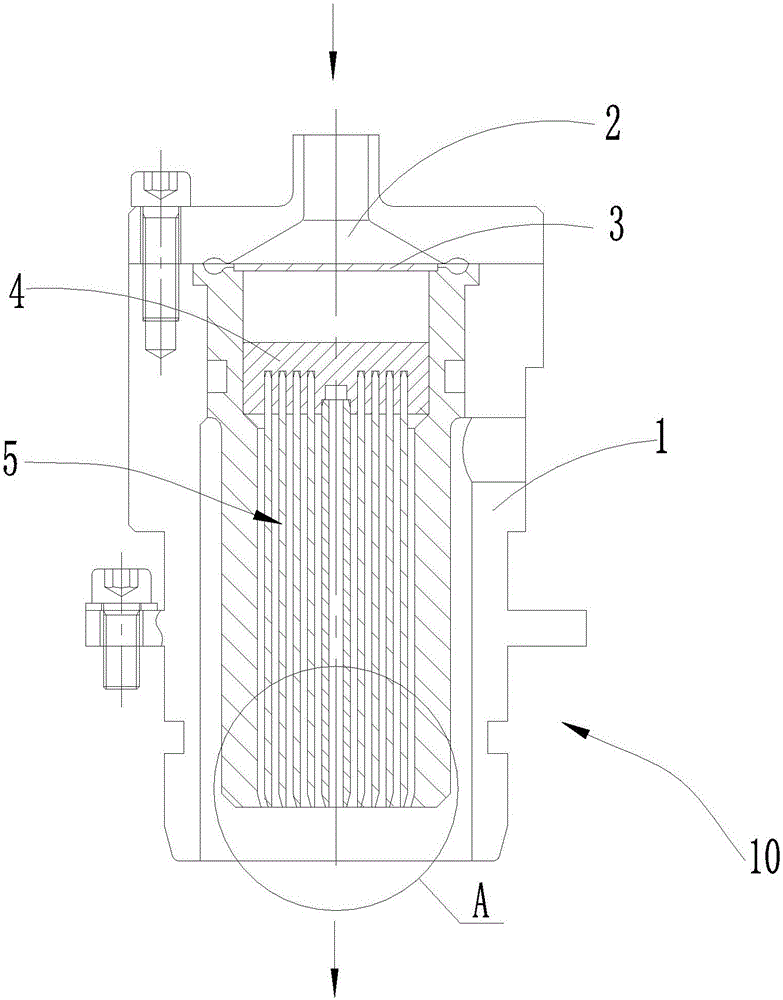

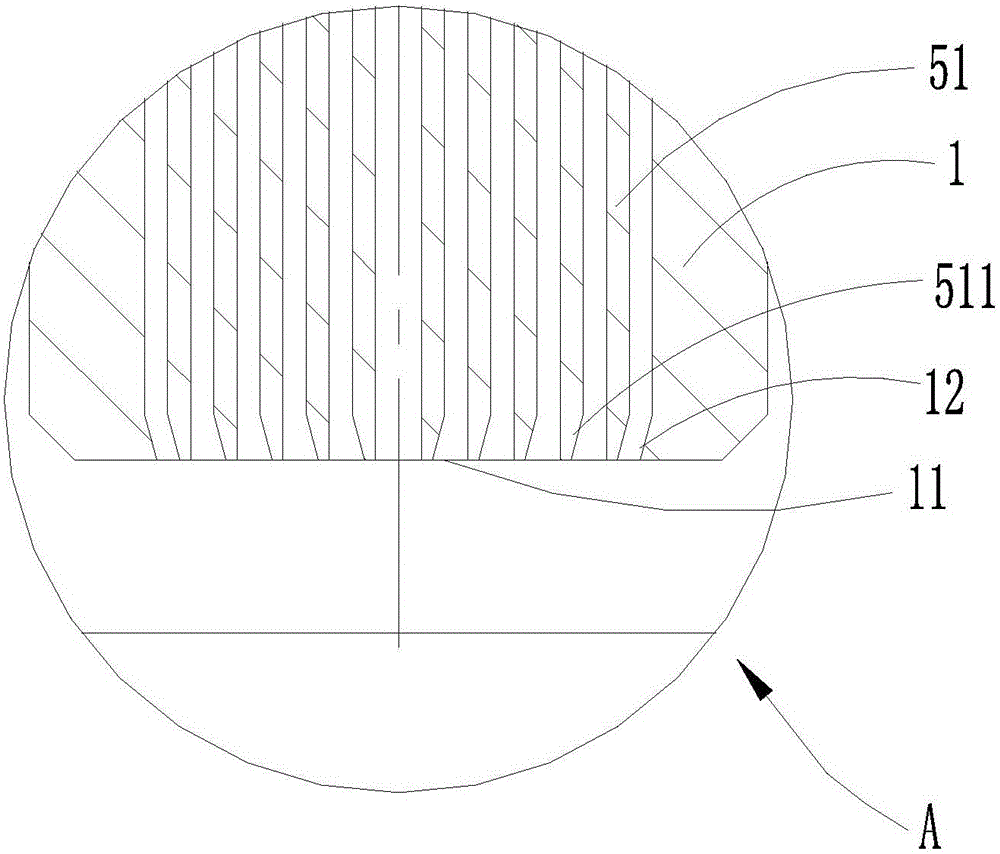

[0021] See figure 2 As shown, a new type of aseptic filling valve 10 includes a valve body with an inner cavity 1, a feed pipe arranged at the upper end of the valve body 1 and communicating with the inner cavity of the valve body 1, an outlet arranged at the bottom of the valve body 1. The filling port 11, the filling valve 10 also includes a diverter plate 3 provided with a diverging hole in the inner cavity of the valve body 1, and a valve core 5 provided below the diverter plate 3 for diversion of the material to be filled, The bracket 4 for installing the valve core 5 is located between the splitter plate 3 and the valve core 5. Here, the outer peripheral side wall of the splitter plate 3 can be sealed with the cavity wall of the inner cavity of the valve body 1, and the length of the bracket 4 is The two ends of the direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com