an electric clipper

An electric clipper and power supply technology, applied in metal processing and other directions, can solve the problems of unreasonable structure setting, complicated and inconvenient assembly, and high manufacturing cost, and achieve the effects of good blade adjustment effect, quick assembly and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

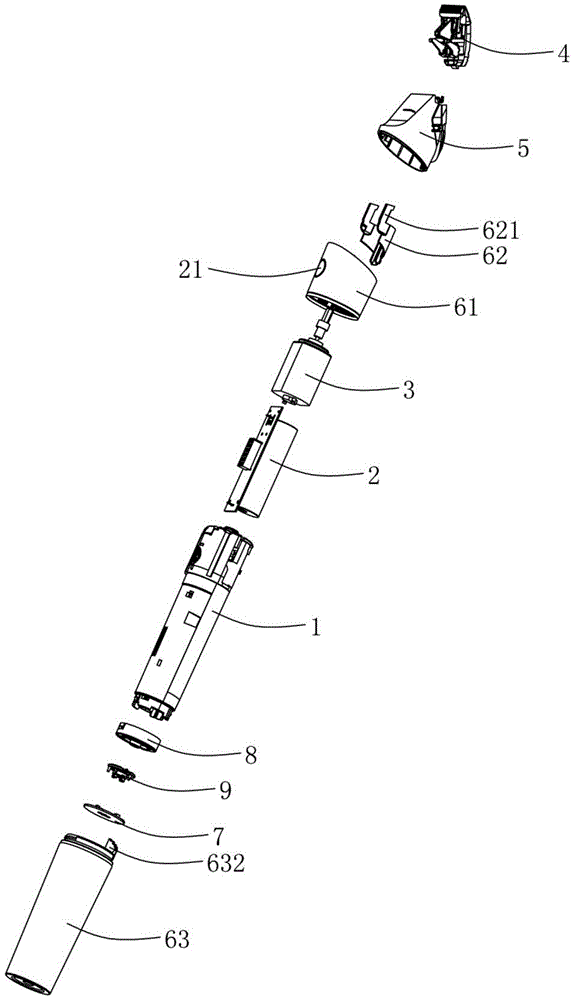

[0028] Such as Figure 1 to Figure 9 The electric clipper shown includes a housing 1, a blade assembly 4 and a blade adjustment mechanism. The housing 1 is respectively provided with a power supply assembly 2 and a motor 3 electrically connected to the power supply assembly 2. The blade assembly 4 includes a mounting plate 41 1. The static blade 42 fixed on the mounting plate 41, the movable blade 43 which is movably located on the mounting plate 41 and driven by the motor 3, the mounting plate 41 is installed on the front end of the housing 1 through the cutter head seat 5, and on the mounting plate 41 Hingedly be provided with the transmission block 44 that matches with movable blade 43, be connected with torsion spring 45 between transmission block 44 and movable blade 43, blade adjustment mechanism comprises adjustment cover 61 and adjustment frame 62, the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com