A processing method for parts with multiple non-processing surfaces

A technology of non-processing surface and processing method, which is applied in the processing of casting parts, valve body and shell parts, and processing fields containing multiple non-processing surface parts. Problems such as difficult curved surfaces, to achieve the effect of reducing the scribing process, shortening the processing cycle, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is further described below in conjunction with the accompanying drawings of the embodiments, but the scope of protection is not limited to the description.

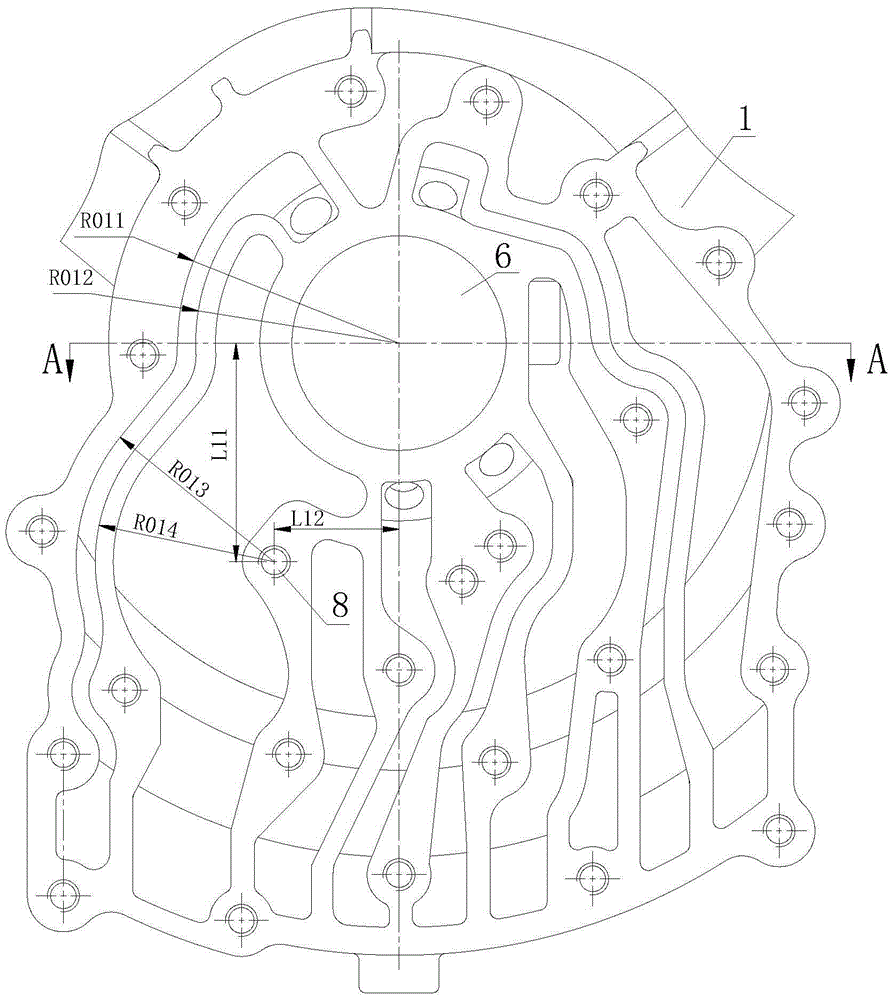

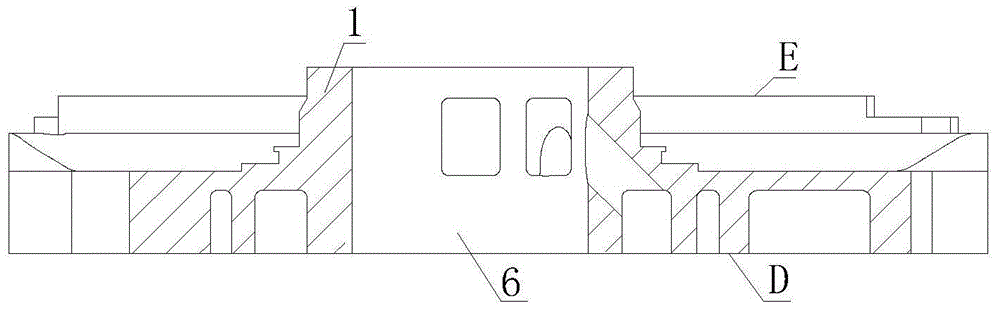

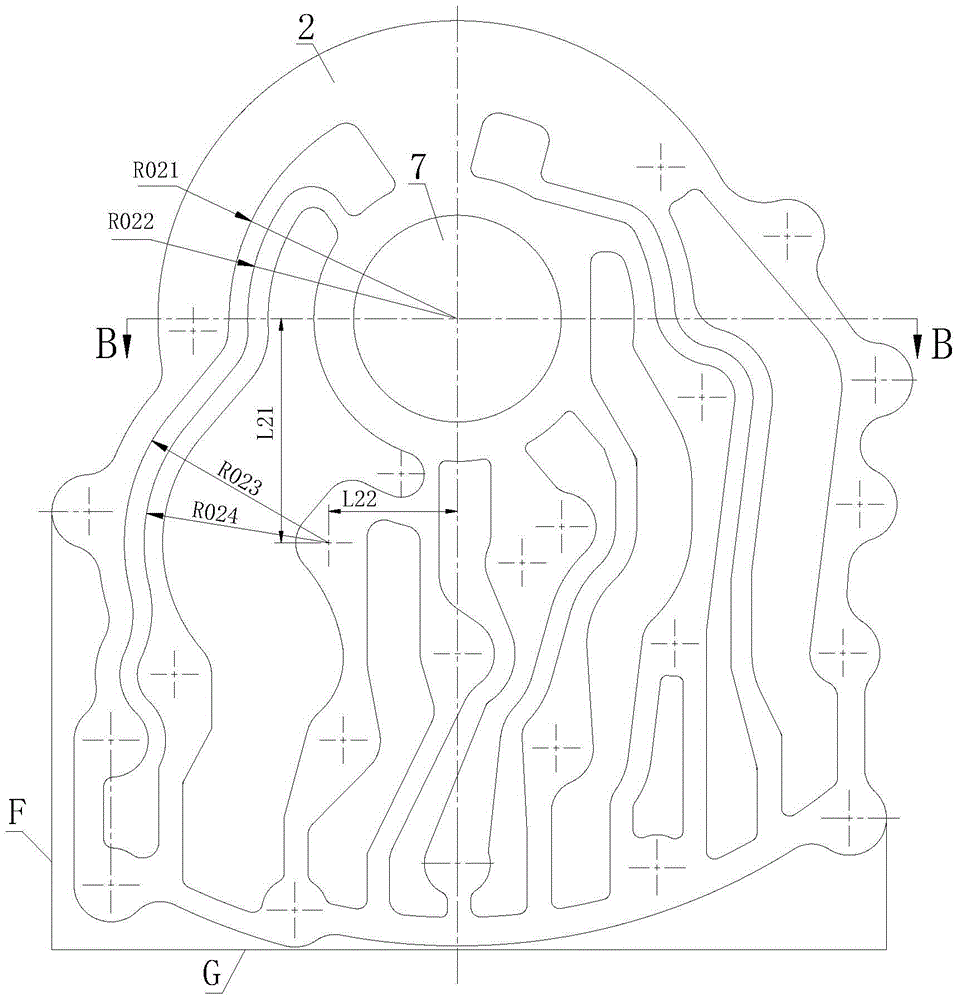

[0035] Such as Figure 1 to Figure 6 As shown, a processing method containing a plurality of non-processing surface parts specifically includes the following steps:

[0036] (1) Make the engraved line positioning template: design the engraved line positioning template 2 according to the processing process of the part 1 and the positional relationship, size and structure of the processed surface and the non-processed surface;

[0037] (2) Parts processing: After the engraved line positioning template 2 is made, the part 1 is processed, and the specific processing steps are as follows:

[0038] A. Rough processing: such as figure 1 , figure 2 As shown, process the D surface and E surface of part 1, and leave a margin of 0.5mm on the D surface and E surface;

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com