Vertical air flue garbage sorting equipment

An air duct and garbage technology, which is applied in the field of vertical air duct garbage sorting equipment, can solve the problems of short falling distance of sorted materials, short process of receiving wind, high labor cost, etc., and achieve good sorting effect, long service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

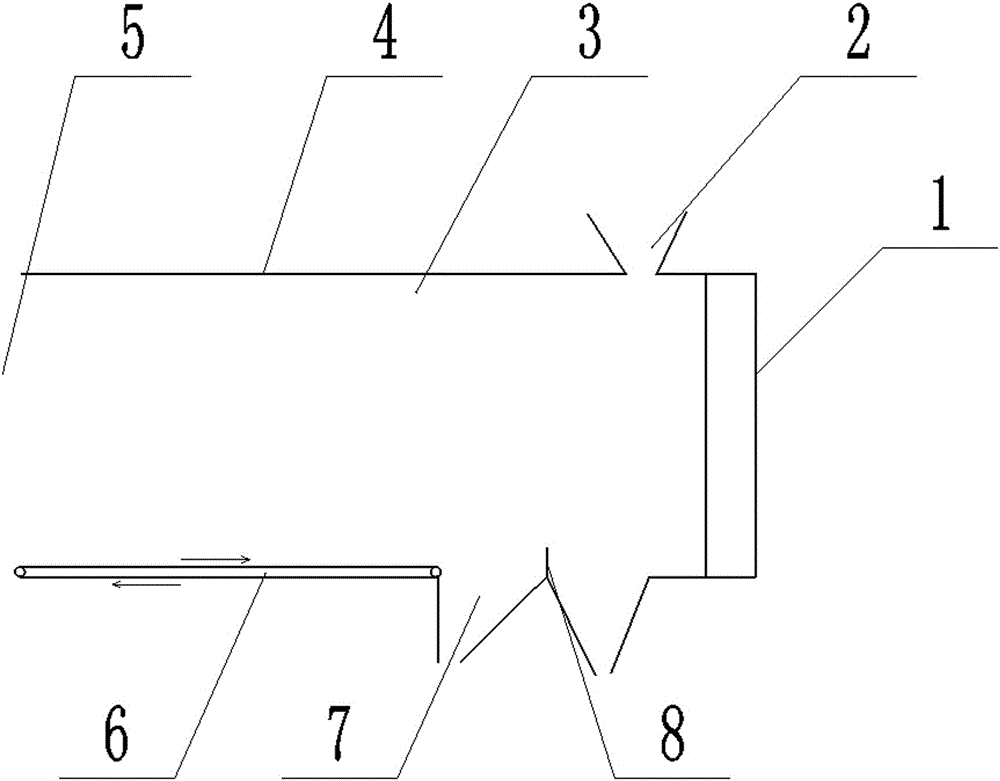

[0015] Such as figure 1 As shown, a vertical air duct garbage sorting equipment includes a fan 1 and a vertical air duct 3 connected to the fan 1. The vertical air duct 3 is provided with a garbage feeding port 2 above and a funnel-type collection device below. 7 and the conveyor belt collection device 6, wherein: there are two funnel-type collection devices 7, which are respectively arranged directly below the feed inlet 2 and close to the fan 1; Farther away, the funnel type collection device 7 and the conveyor belt collection device 6 are separated by a partition 8 .

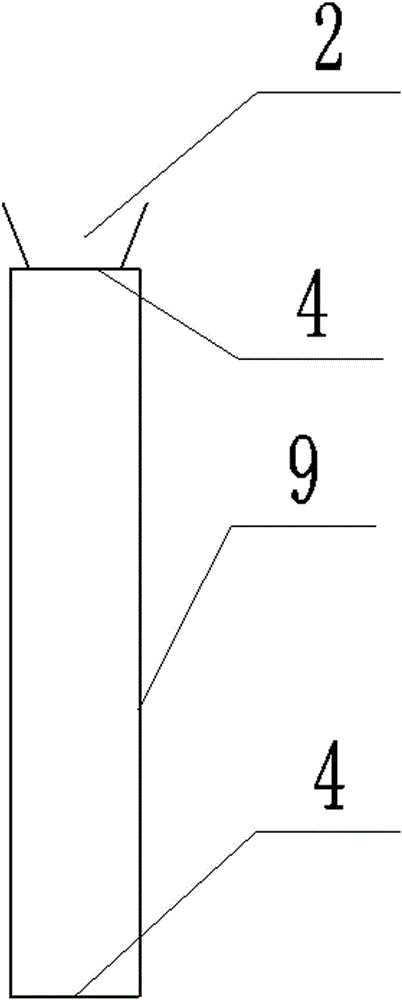

[0016] The cross-section of the vertical air duct 3 is a horizontal air duct (such as figure 1 As shown), the longitudinal section is "1" shaped air duct (such as figure 2 As shown), side windshields 9 are respectively provided on both sides of the air duct 3, and the height and length of the windshields 9 are hollow structures greater than the size of the upper and lower windshields 4 of the air duct.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com