Cable force measuring method for suspender cable of suspension bridge

A measurement method and technology for slings, which are applied in the fields of instruments, calculations, electrical and digital data processing, etc., can solve problems such as the cable force of suspension bridges that have never been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

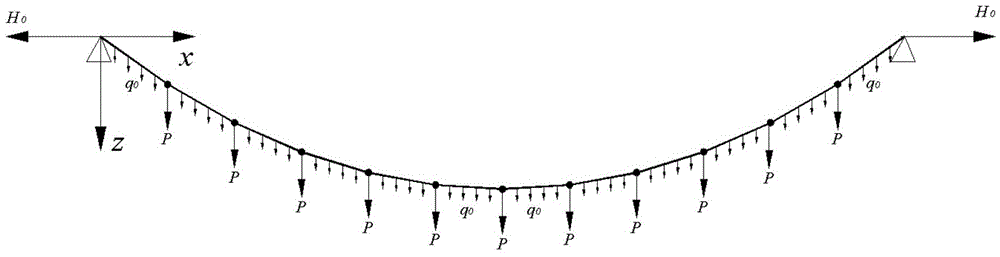

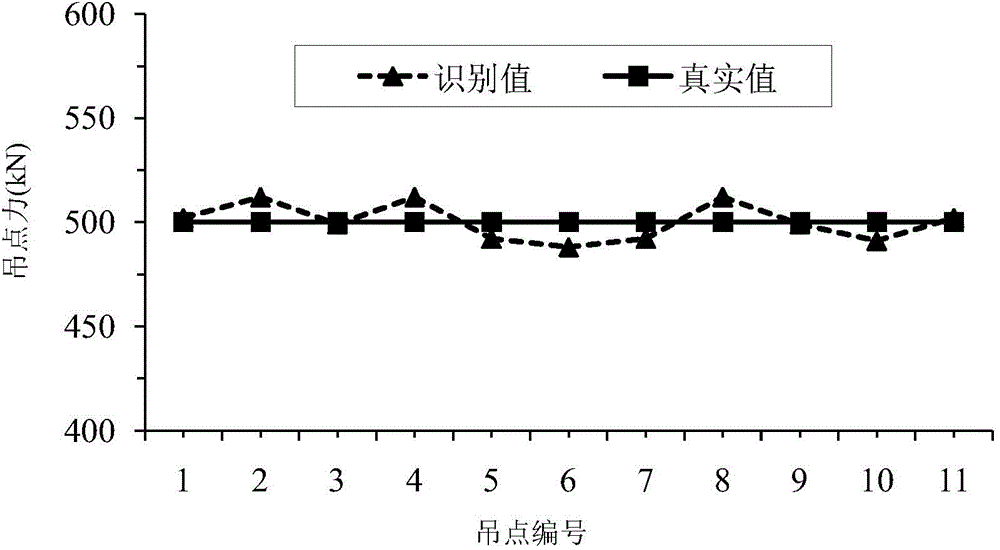

[0035] The cross-sectional area of a single suspension cable is A=1200cm 2 , modulus of elasticity E=195GPa, self-weight of the cable is q 0 =100N / m, the horizontal tension at both ends of the cable is H 0 =12000N, the same concentrated load P=500N acts on the 11 twelfth points in the middle, the model of the single suspension cable is as figure 1 shown.

[0036] The present invention starts from the principle of mechanical balance of the micro-section of the suspension cable, obtains the analytical expression of the element stiffness matrix by solving the equilibrium differential equation of the element, and constructs an accurate catenary element that can be used for form-finding of the suspension cable. The finite element analysis method obtains a suspension cable form-finding method, and then obtains a suspension bridge suspension cable force measurement method according to the suspension cable form-finding method.

[0037] The form-finding method of the suspension ca...

Embodiment 2

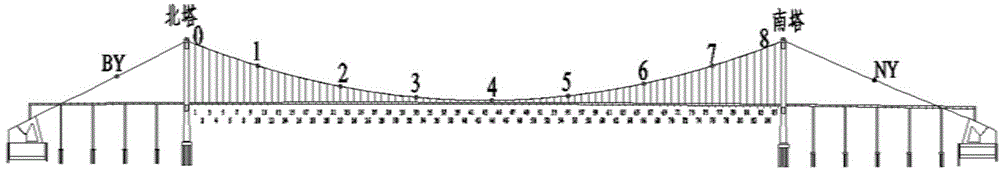

[0055] Taking the Pearl River Huangpu Bridge as an example below, the present invention is used to identify the sling force of each sling, and the sling force identification steps are as follows:

[0056] (1) Use the method of measuring three-dimensional coordinates to measure the shape of the main cable

[0057] Take the plane and elevation control points ZJ13, ZJ15, ZJ16, and DC10-3 of the Huangpu Bridge provided by the Pearl River Huangpu Bridge Measurement Center as the starting point to directly measure the three-dimensional coordinates of the eighth point of the main cable. The specific measurement point layout is as follows: image 3 shown. The measuring instrument used is Leica TCA1201+ total station, with prism distance measurement accuracy: 1mm+1.5ppm, without prism distance measurement accuracy: 2mm+2ppm, angle measurement accuracy 1″.

[0058] For long-span suspension bridges, the shape of the main cable changes all the time, and it is difficult to accurately obta...

Embodiment 3

[0087] Taking the Aizhai Super-Large Bridge as an example, the sling force of each sling is identified below. In this embodiment, Matlab software is used to compile the sling force identification program of the method of the present invention to realize one-time identification of all sling forces.

[0088] (1) Measure the main cable shape

[0089] The measuring points of the main cable of Aizhai Bridge are as follows: Figure 7 As shown, the measured results of the main cable alignment are shown in Table 5, and the comparison between the measured alignment and the designed alignment is shown in Figure 8 shown.

[0090] Table 5 Measuring point coordinate test results (unit: m)

[0091]

[0092]

[0093] It can be seen from the figure that the measured value of the main cable alignment is generally in good agreement with the design curve, and the largest error occurs at the position between measuring points 6 and 7.

[0094] (2) According to the physical parameters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com