Metal mobile phone frame and production method thereof

A production method and metal frame technology, applied to the structure of telephones, etc., can solve problems such as bending of mobile phones, affecting the use or scrapping of mobile phones, and small bending force, so as to achieve the effect of protecting the screen of mobile phones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below, but not as a limitation of the present invention.

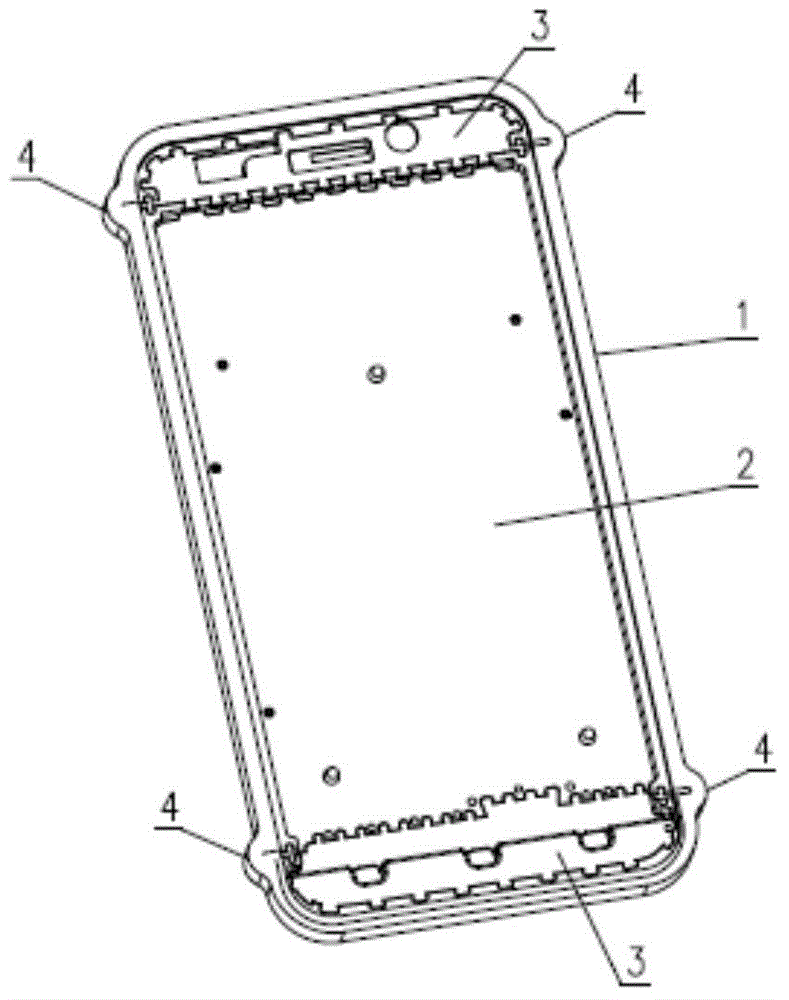

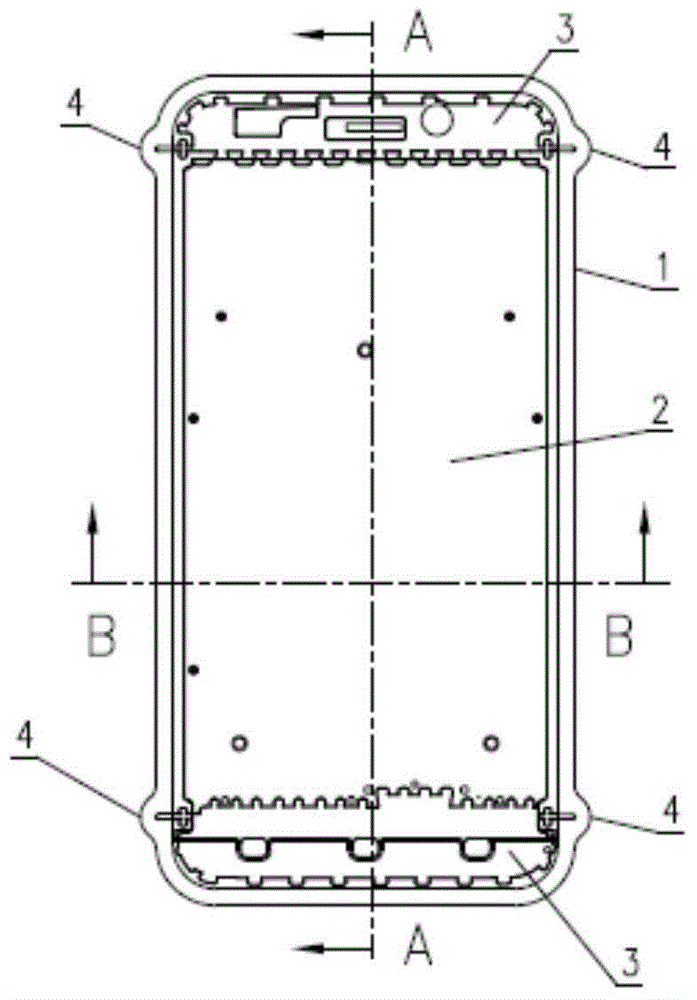

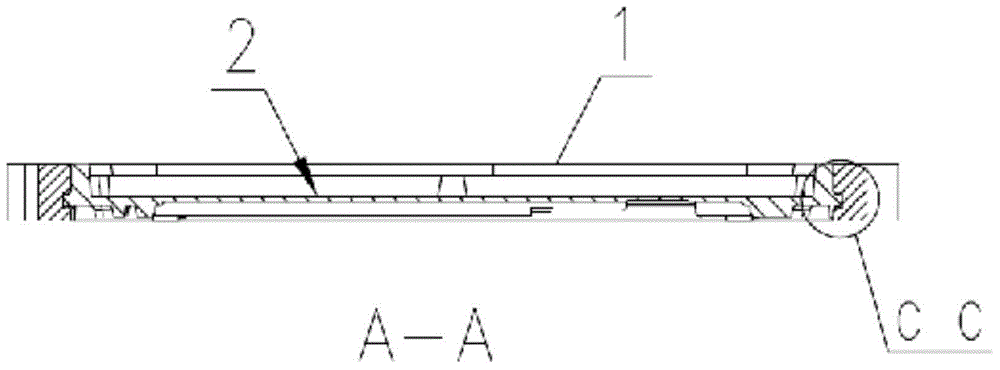

[0055] Such as Figure 1 to Figure 18 As shown, a metal mobile phone frame provided by the present invention includes a metal outer frame 1, the inner wall of the metal outer frame 1 is provided with a dovetail card slot 11, and the middle part of the metal outer frame 1 is provided with a metal area 2. Both ends of the metal frame 1 are provided with plastic areas 3 , and the metal area 2 and the plastic area 3 are fixedly connected to the metal frame 1 through the dovetail slot 11 .

[0056] Specifically, such as Figure 1 to Figure 18 As shown, the metal frame 1 is made of aluminum profile or stainless steel profile. The metal area 2 is die-cast from aluminum alloy, magnesium alloy or zinc alloy. The plastic area 3 is molded by secondary injection molding of ABS or ABS+PC. The wall thickness of the metal outer frame 1 is 1 to 2 mm, preferably 1.5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com