Screening device for sugarcane harvester

A technology for screening devices and harvesters, which is applied to harvesters, agricultural machinery and implements, and applications, and can solve problems such as inability to ship goods quickly, long screening time, and uneven lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

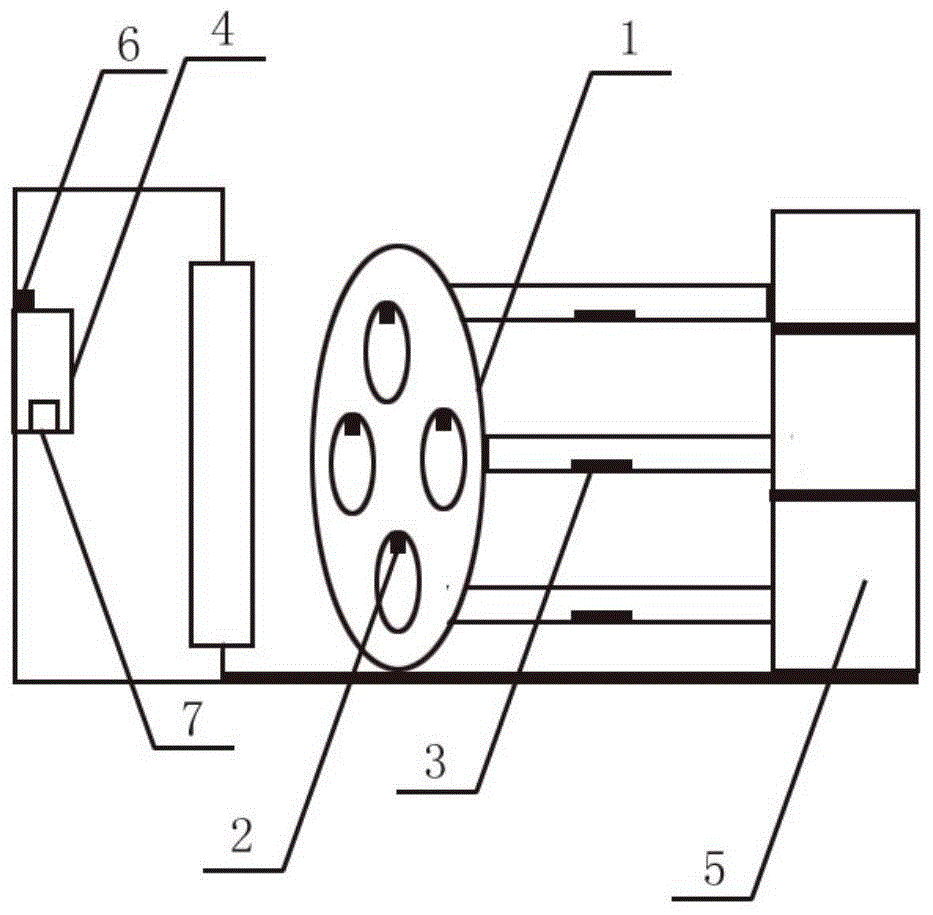

[0012] Embodiment: as shown in the accompanying drawing. A screening device for a sugarcane harvester, comprising a frame (1), the frame (1) is in the form of a disc structure connected to the outlet of the sugarcane harvester body, the sugarcane is directly screened through the frame (1), and a plurality of Channel, the upper part of the channel entrance is equipped with a length detection module (2), and the internal conveying pipeline is equipped with a weight monitoring module (3). Indicators, adjust different conveying pipelines to divide the sugarcane into different collection devices (5).

[0013] A screening device for a sugarcane harvester, the frame (1) adopts a rotating mode, includes detection and screening functions, and is quickly separated according to the instructions of the central control device (4).

[0014] A screening device for a sugarcane harvester, the collection device (5) is divided into multiple levels, and corresponding numbers are set, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com