Inner basket for a multi-plate clutch

A multi-disc clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of high manufacturing cost and complex multi-disc clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

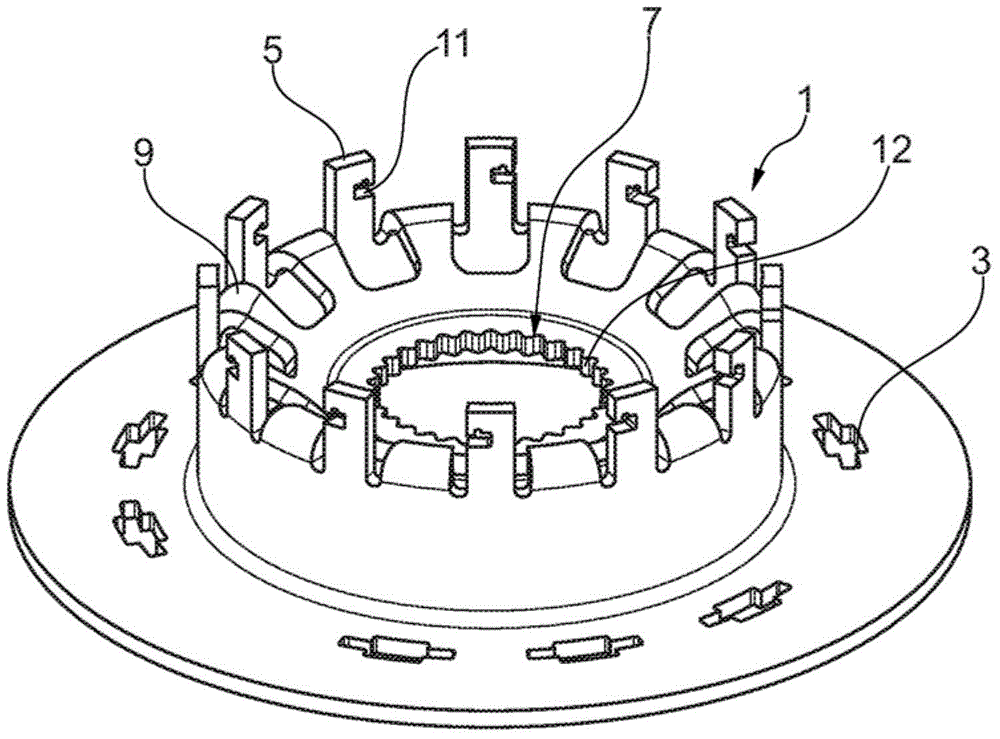

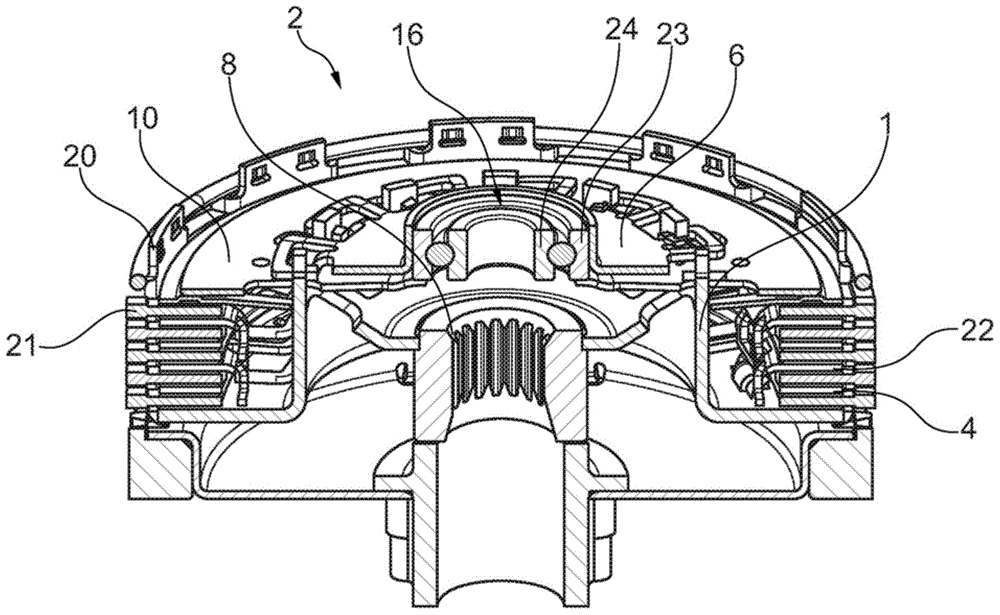

[0030] figure 1 The inner shell 1 is shown deep-drawn from a sheet metal part. The inner housing has a first receptacle 3 for the friction lining 4 , a second receptacle 5 for the support disc 6 , a third receptacle 7 for the hub 8 , and a bracket 9 for the disc spring 10 . Each component is in image 3 shown in . The second receiving part 5 comprises a loss safety device 11 in which a safety pin 14 can be inserted (see figure 2 ). The third receptacle 7 comprises an internal toothing 12 with which the hub 8 can be wedged axially.

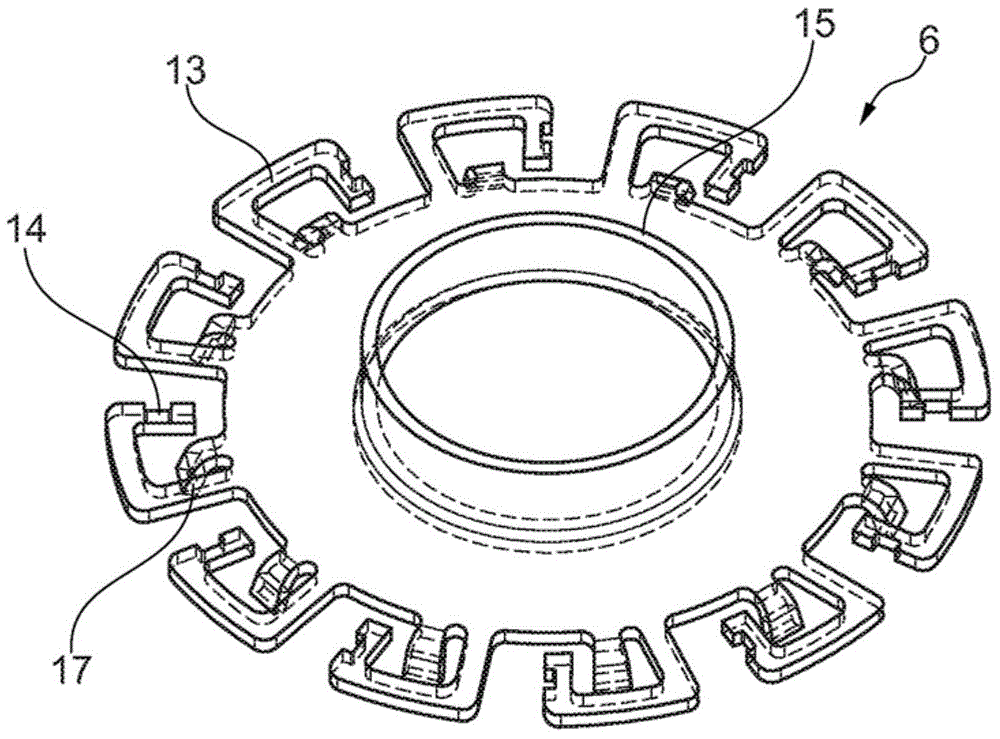

[0031] exist figure 2 A support disk 6 is shown in , which forms a spring element 13 , a safety pin 14 and a support receptacle 15 for a radial engagement bearing 16 . The support disc 6 is also formed from a sheet metal part. The safety pin 14 forms an elevation 17 which forms a seat for the disk spring 10 . These components are also image 3 shown in .

[0032] exist image 3 shows a multi-plate clutch 2 in which the arrangement as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com