Fixture for mechanical shock test on power semiconductor module, and test method

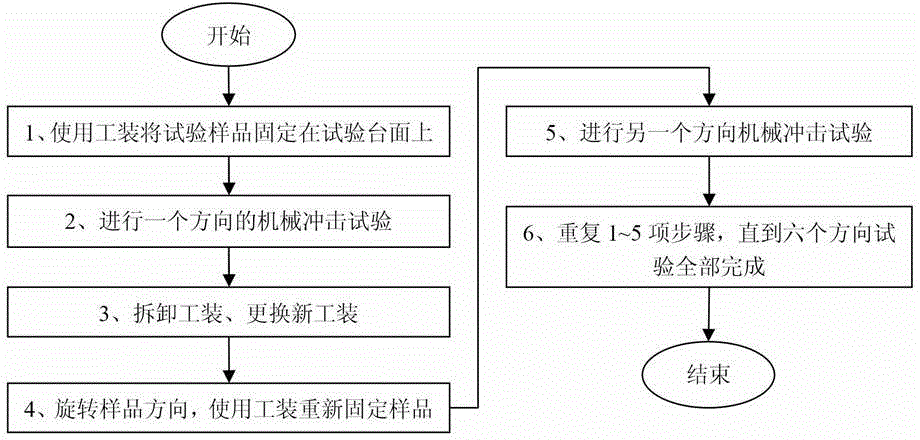

A power semiconductor, mechanical shock technology, applied in shock testing, machine/structural component testing, measuring devices, etc., can solve problems such as sample damage and module shell rupture, achieve consistent fixing methods, avoid shell damage, and simplify Effects of the Mechanical Shock Test Procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

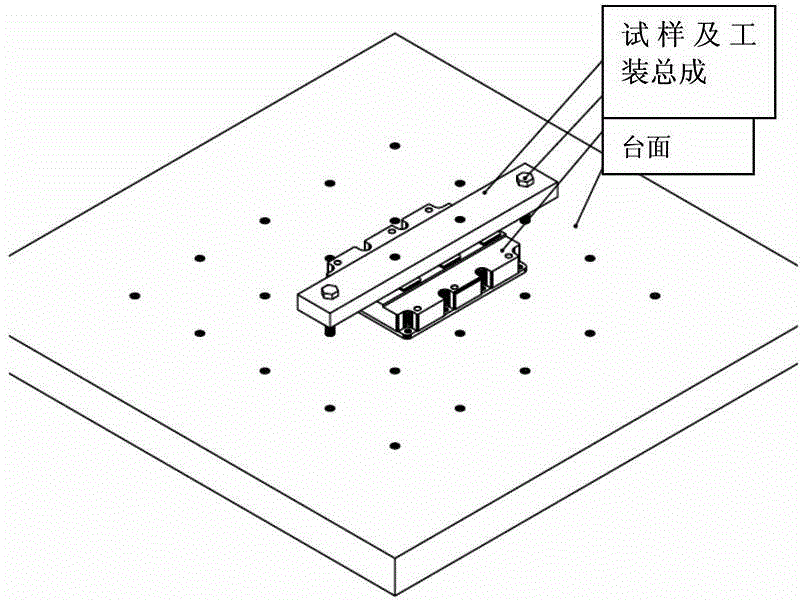

[0054] Such as Picture 10 , Picture 11 , Picture 12 with Figure 13 As shown, the tool for mechanical impact testing of power semiconductor modules of the present invention includes a square bottom plate 1 and four side plates 2. The four side plates 2 are perpendicular to the bottom plate 1 and are respectively located on one side of the bottom plate 1. The bottom plate 1 There is a sample mounting hole 4 for fixing the test sample 3, two of the four side plates 2 form a group in parallel, and the side plates 2 of one group are provided with a first installation in the X-axis direction on the mounting table of the test bench. Fixed mounting hole 5, the side plate of the other group is provided with a second fixed mounting hole 6 for installation in the Y-axis direction of the test bench installation table, and the bottom plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com