Automatic intelligent filling and conveying device

A conveying device and filling technology, applied in the direction of conveyor objects, packaging, bottle filling, etc., can solve problems such as low efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

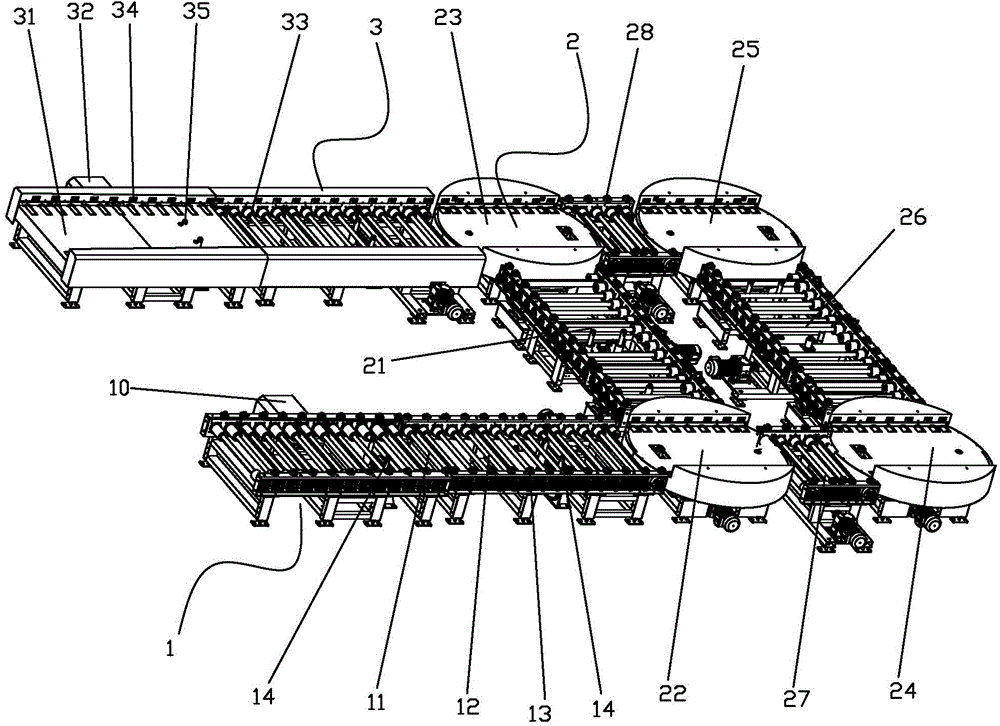

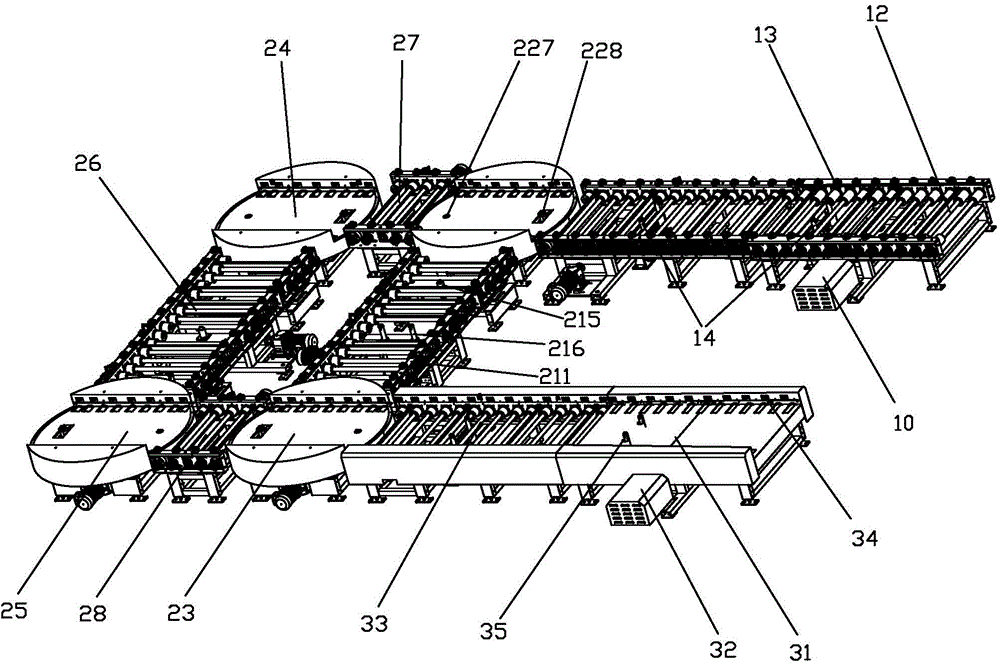

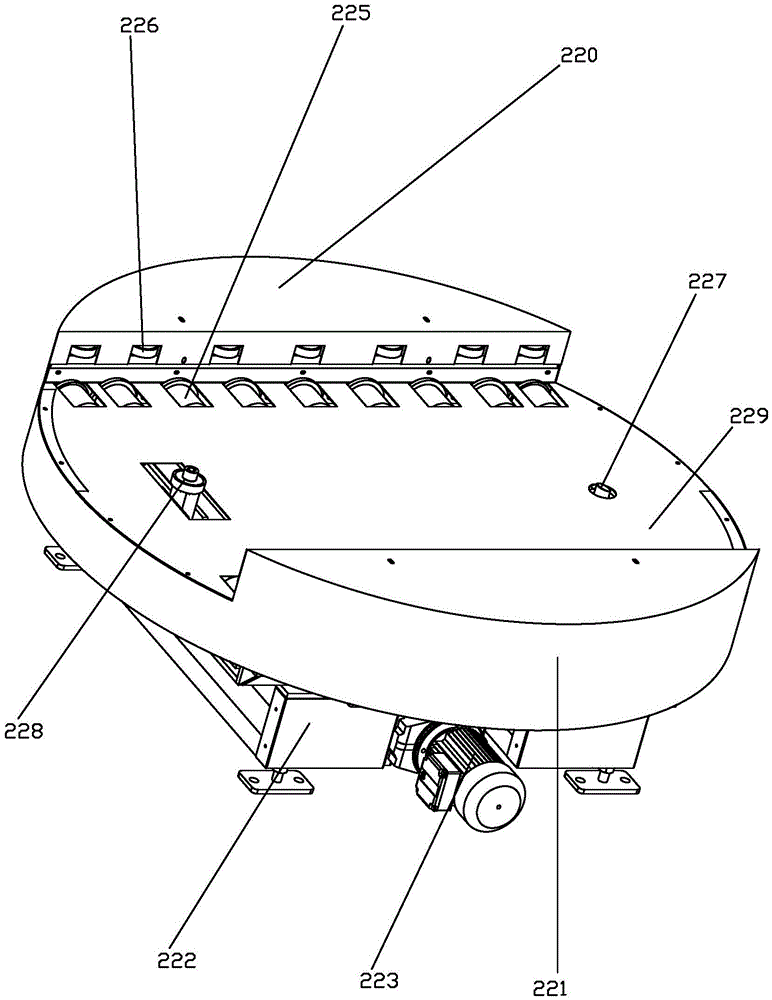

[0024] An automatic intelligent filling and conveying device, comprising a filling container feeding and conveying device 1, one side of the filling container feeding and conveying device 1 is provided with a filling container discharging and conveying device 3 side by side, and the filling container Between the output end of the container feeding conveying device 1 and the input end of the said filling container discharging conveying device 3, there is a device capable of controlling the filling amount and weighing the filling amount at the same time and feeding the filled container to the said filling container. The weighing filling and conveying device 2 conveyed by the container discharge conveying device 3, the weighing filling and conveying device 2 includes a first filling and weighing part 21, and the input end of the first filling and weighing part 21 is connected to the Between the output ends of the filling container feeding and conveying device 1, there is a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com