Tree excavating machine outer meshing rotating driving device

A rotary drive, external meshing technology, applied in transmission, mechanical equipment, forestry and other directions, can solve the problems of eccentricity, unsteady digging, and inability to adjust the size of the side screw-in soil ball.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

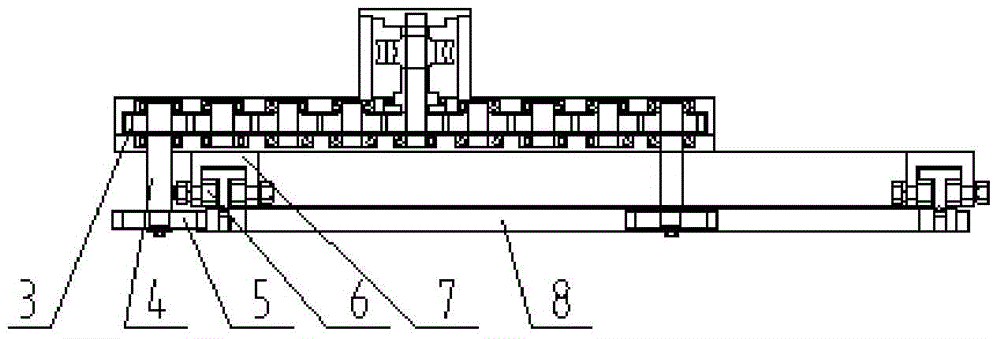

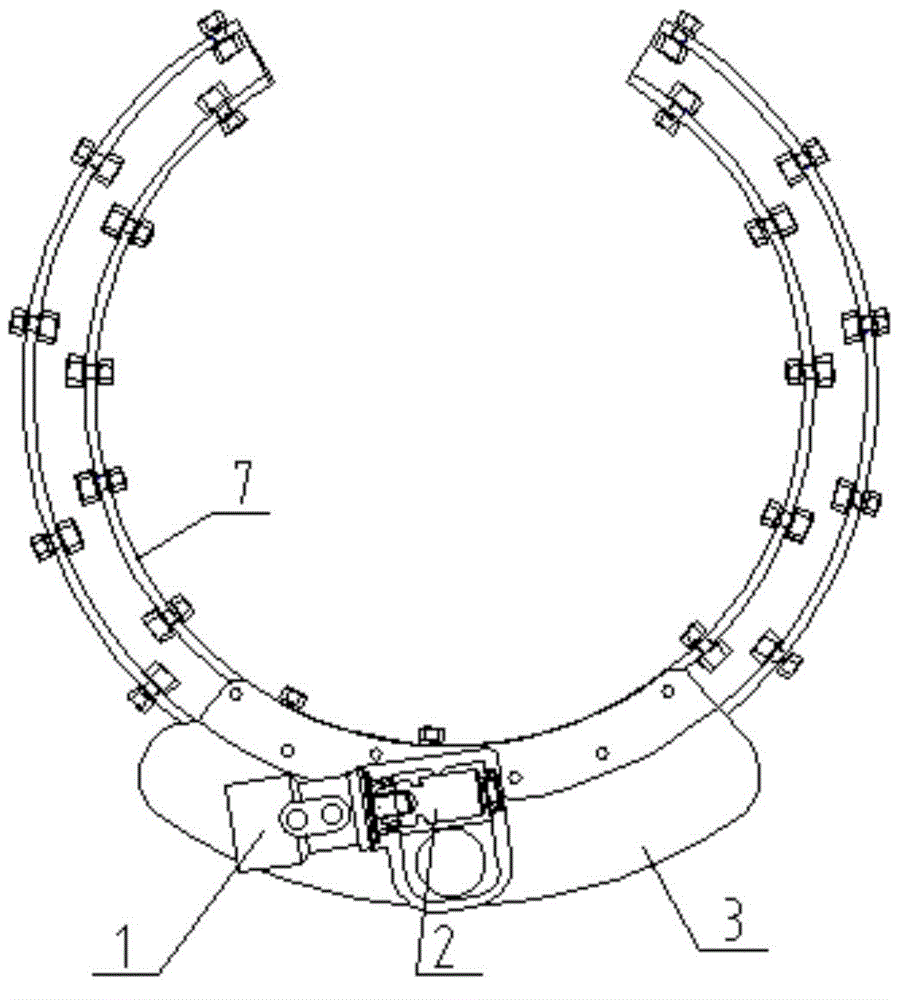

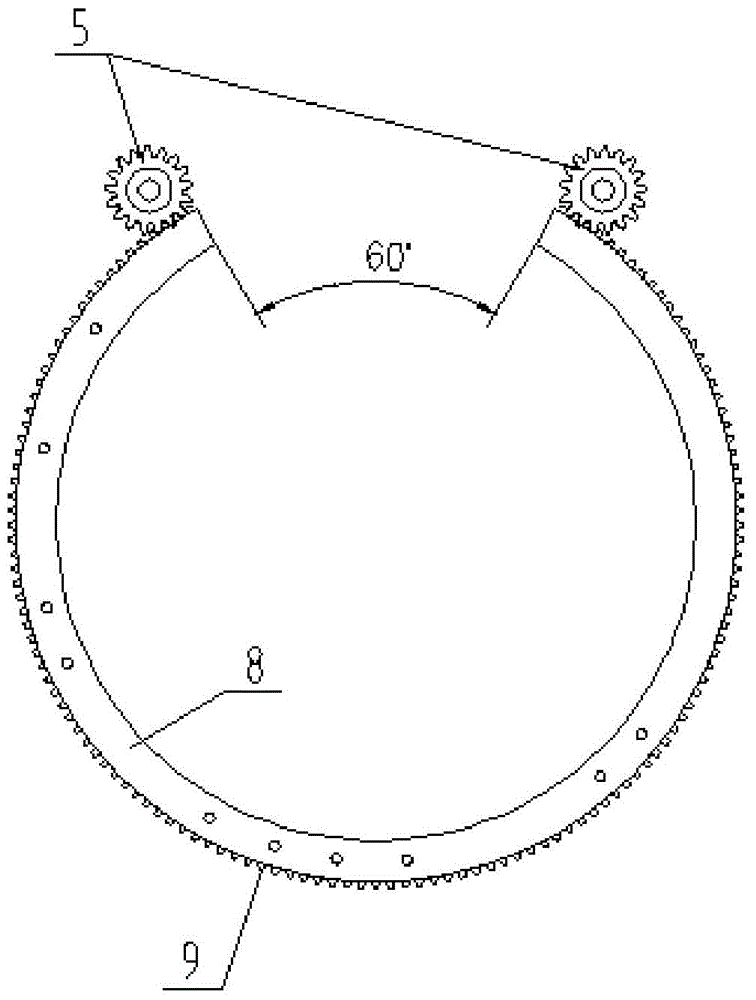

[0016] Referring to the accompanying drawings, an external meshing slewing drive device for a tree digging machine includes a supporting upper ring 7, a supporting lower ring 8, and a drive motor 1, a worm gear reduction mechanism 2, a transfer case 3, and a transfer case 3 that are sequentially connected by transmission. Installed on the supporting upper ring 7, the driving motor 1 and the worm gear reduction mechanism 2 are respectively installed on the transfer case 3, the supporting lower ring 8 is installed on the bottom of the supporting upper ring 7, and the supporting upper ring 7 and the supporting lower ring 8 One side is respectively provided with openings with the same angle; the two ends of the transfer case 3 are respectively rotated and installed with a transmission shaft 4, the lower end of the transmission shaft 4 is respectively equipped with a gear 5, and the supporting lower ring 8 has an outer ring gear 9, and the gear 5 is respectively connected to the The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com