Non-glue mechanical sealing structure of fiber grating osmometer

A technology of optical fiber grating and mechanical sealing, which is applied in the direction of fluid pressure measurement using optical methods, can solve the problems of poor sealing stability, poor sealing effect, and affecting the precision of piezometer, and achieve the effect of protecting the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

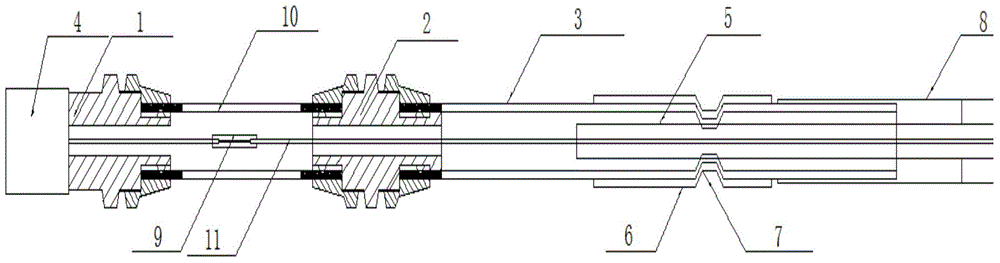

[0014] The present invention is described in detail below in conjunction with accompanying drawing:

[0015] A fiber grating piezometer adhesive-free mechanical seal structure, including a fiber grating piezometer 4 composed of a fiber grating, characterized in that a pressure-resistant quick-twist one-way joint 1 and the fiber grating piezometer 4 are butted through threads, The other end of the pressure-resistant quick-twist one-way joint 1 is a threaded nut structure, and one end of the first segment of nylon tube 10 is sealed and installed on the pressure-resistant quick-twist one-way joint 1 through the threaded nut structure of the pressure-resistant quick-tighten one-way joint 1 At the other end, the optical fiber 11 protruding from the fiber grating piezometer 4 passes through the pressure-resistant quick-twist one-way joint, and the optical fiber fusion splice 9 is placed in the first section of nylon tube 10, and the other end of the first section of nylon tube 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com