CVT

A continuously variable transmission, input shaft technology, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problems of excess lubricating oil and poor efficiency, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

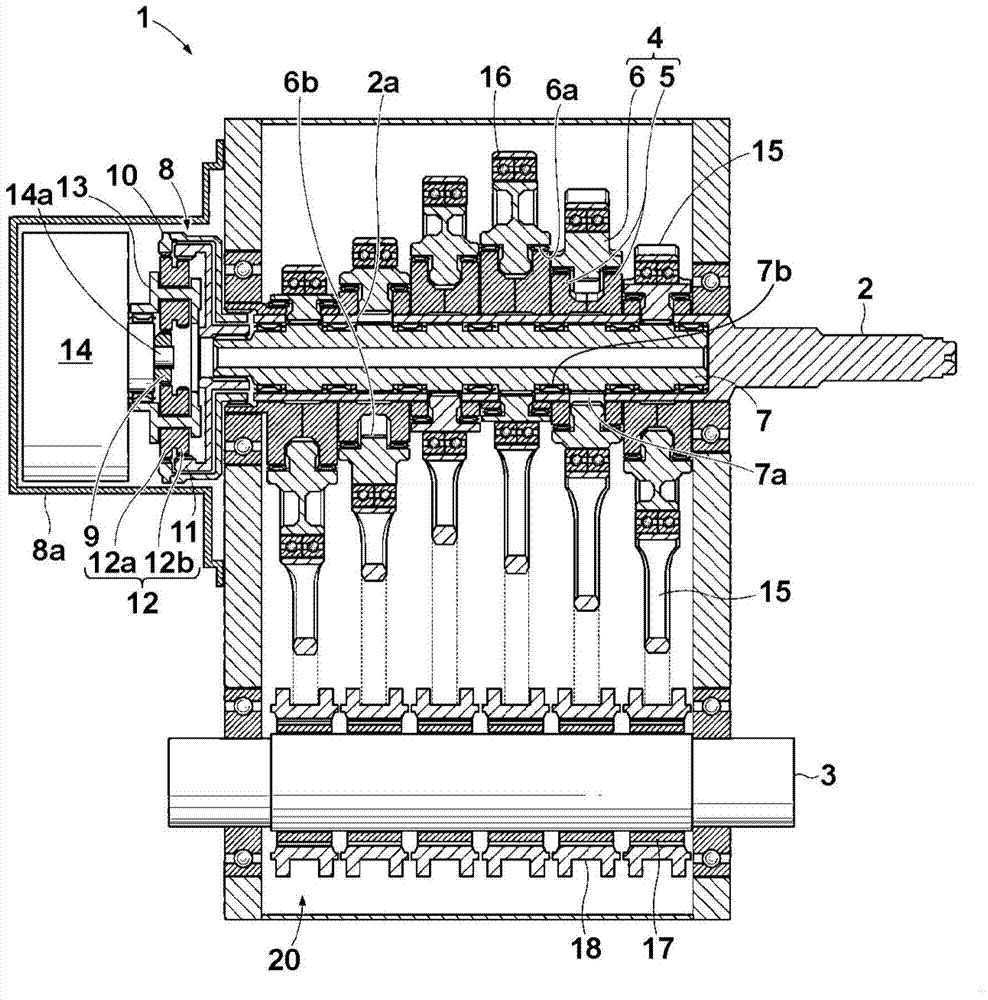

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the embodiment described below is an example of the implementation means of this invention, and this invention is applicable to the structure which modified or deform|transformed the following embodiment in the range which does not deviate from the summary. In addition, it goes without saying that the continuously variable transmission of the present invention can be applied to applications other than automobiles.

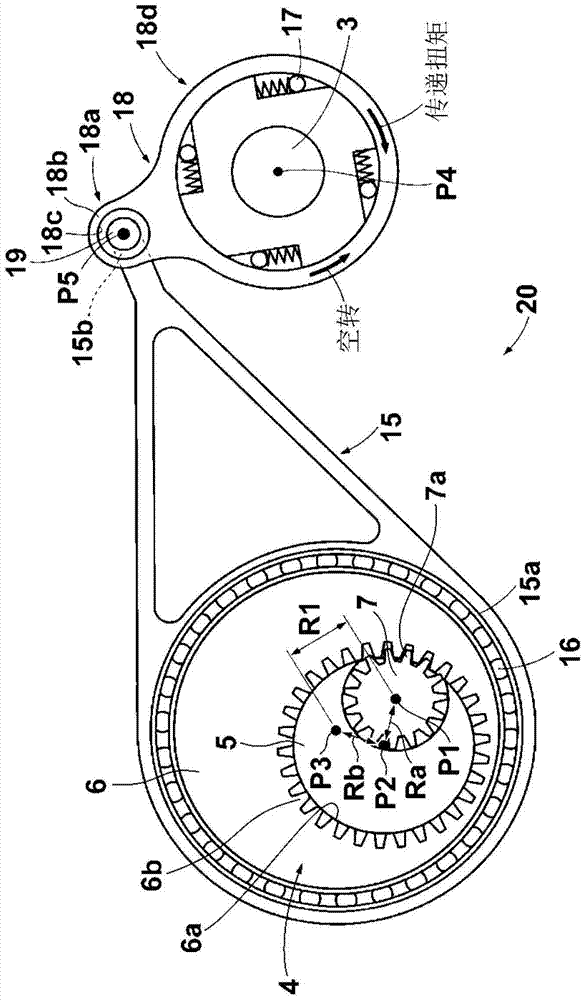

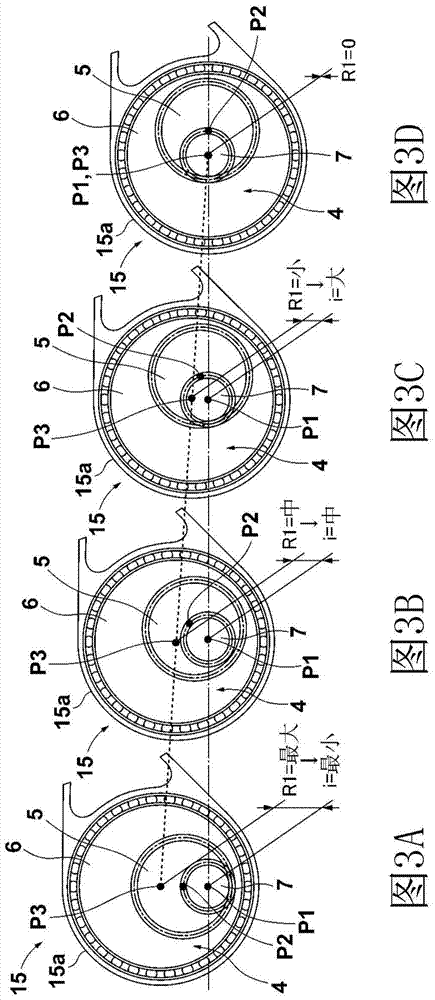

[0028] First, refer to figure 1 and figure 2 , the structure of the continuously variable transmission of this embodiment will be described.

[0029] The continuously variable transmission 1 of the present embodiment is a transmission capable of making the speed ratio i (i=rotational speed of the input shaft / rotational speed of the output shaft) infinite (∞) and making the rotational speed of the output shaft "0", that is, It is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com