Method for predicting waving form of thin cold-rolled strip steel in width direction

A prediction method, thin strip steel technology, applied in the field of strip rolling, can solve the problems of complex wave forms of cold rolled strip steel, no obvious rules along the width direction, and difficulty in reflecting deformation laws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

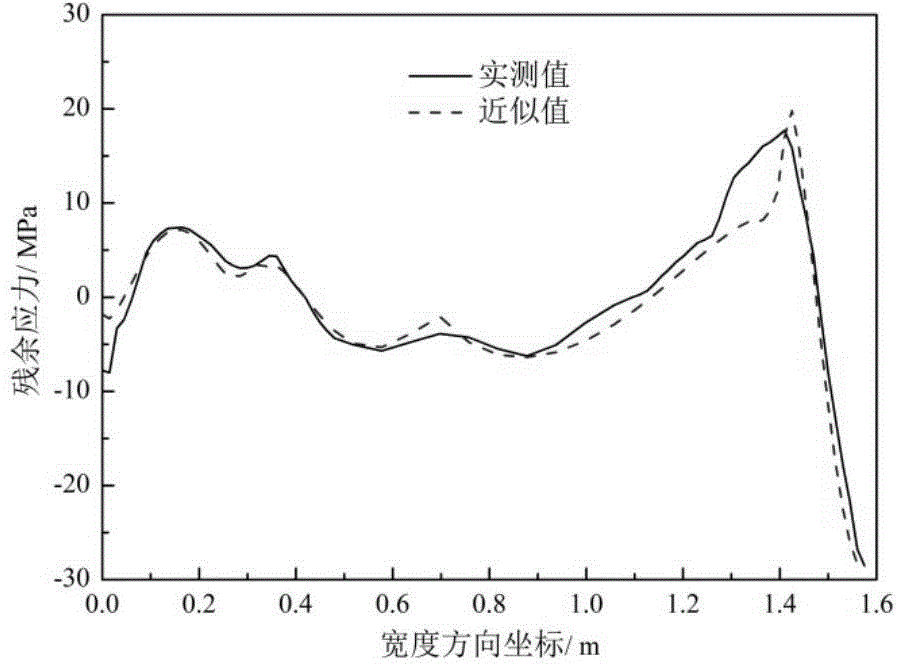

[0082] The technical solutions of the present invention will be further described below in conjunction with the embodiments. Table 1 shows the measured residual stress values of a coil of cold-rolled strip steel on a certain cross-section in a factory, including a total of 76 detection points.

[0083] Table 1 Measured value of residual stress of a coil of cold-rolled strip steel on a certain cross-section in a factory

[0084]

[0085]

[0086] Therefore there

[0087] σ=(-7.7702,-8.0203,-3.3241,...,-21.7170,-26.7423,-28.5301)

[0088] r=(0,0.0150,0.0300,…,1.5450,1.5600,1.5750)

[0089] 1. Calculate the left auxiliary vector σ left and the right auxiliary vector σ right

[0090] According to the measured residual stress value σ of cold-rolled thin strip steel, the left auxiliary vector σ is calculated by formula 1 left and the right auxiliary vector σ right , for further analysis.

[0091] σ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com