Glue dipping machine for preparing hollow capsules

A hollow capsule and glue-dipping machine technology, which is used in capsule transportation, pharmaceutical formulations, and drug delivery, etc., can solve the problem of high cost of cleaning the glue tank and debugging of glue solution, small stripping and reversing of the strip, and increased fatigue. problems, to achieve the effect of saving manpower and material costs, eliminating strips and reversing strips, and improving clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

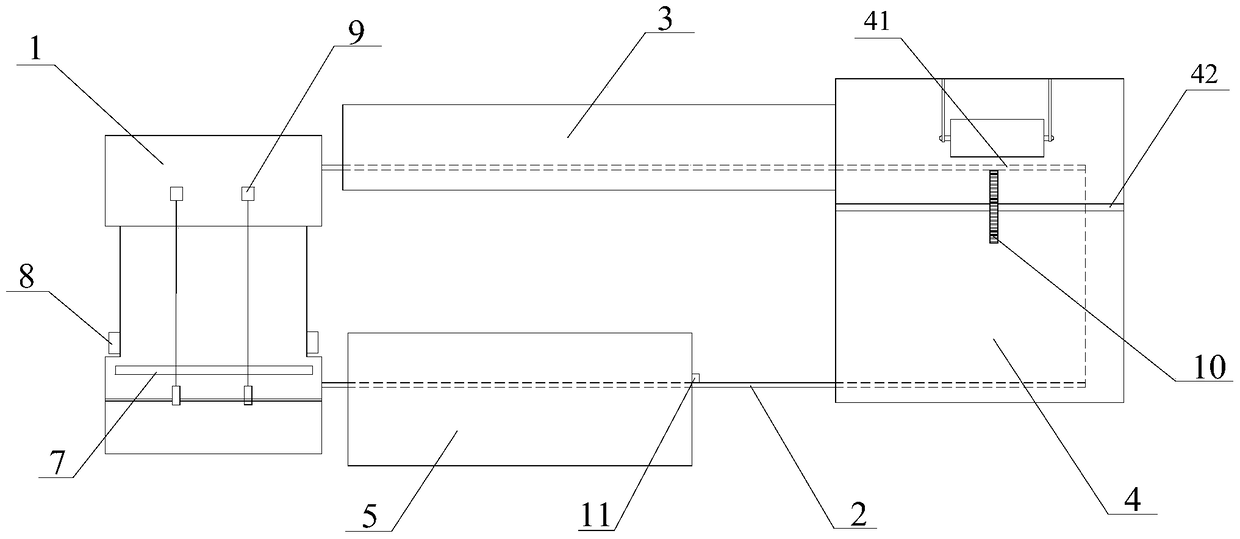

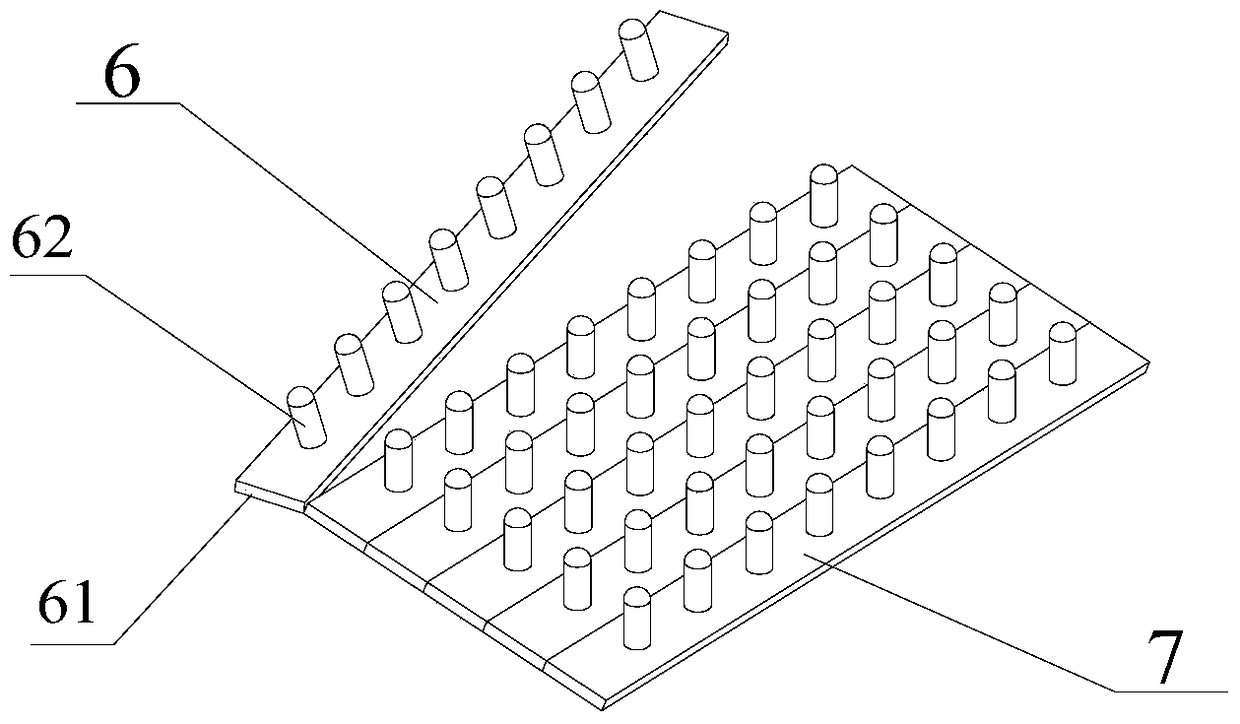

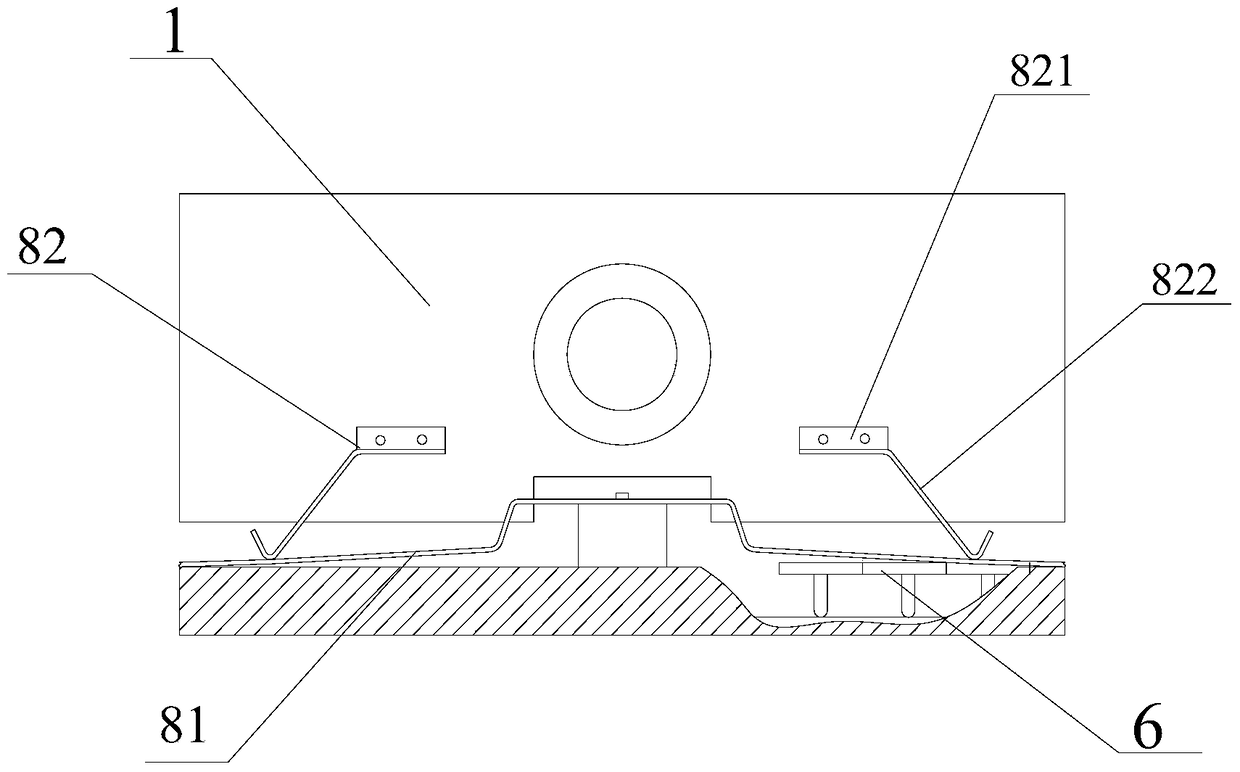

[0026] Such as Figure 1-2 As shown, a hollow capsule preparation device includes a glue dipping machine 1, a circulating template delivery track 2, a drying and cooling chamber 3, an electrostatic removal reaction chamber 4, a demoulding device 5, and a small dial 6. The circulating template The transport track 2 connects the glue dipping machine 1, the drying and cooling chamber 3, the static removal reaction chamber 4 and the demoulding device 5 in series to form a circulation system. The small dial 6 includes a base 61 and a Die head 62, the several small dial strips 6 are assembled into a large dial template 7 by splicing between bases 61 . The dipping machine 1 includes two large dial templates 7 on each side, a small dial mold retaining device 8, and a template anti-dropping device 9, and the small dial mold retaining device is arranged 8 before and after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com