Thread inspecting device of nut thread inspecting machine

A detection device and inspection machine technology, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve problems such as jamming, inaccurate results, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific examples.

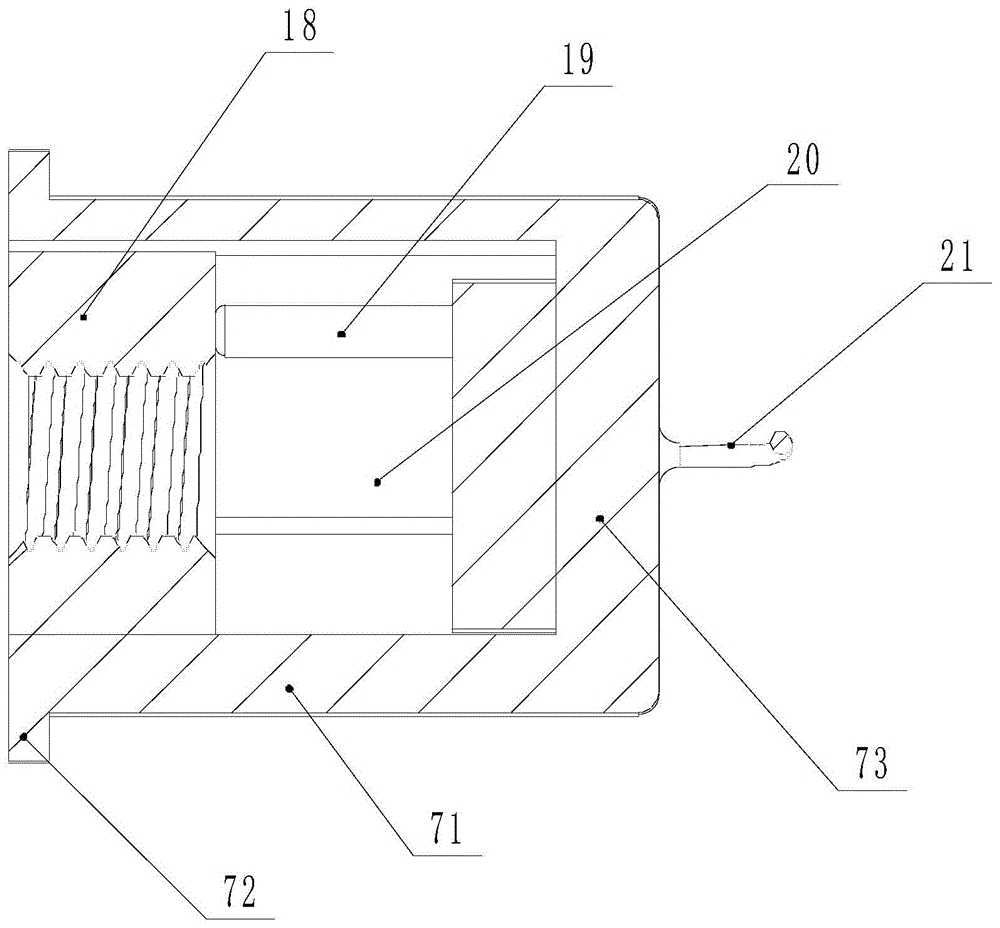

[0025] The present invention described before is determined by the running direction of the nut 18 on the output shaft 3, the forward direction is the front, and the backward direction is the rear, and for the output shaft 3 of the motor 2, one end of the output shaft 3 is a free end, Therefore, the free end of the output shaft 3 is provided with inspection threads, the end of the free end of the output shaft 3 is the head, and the corresponding position is the tail.

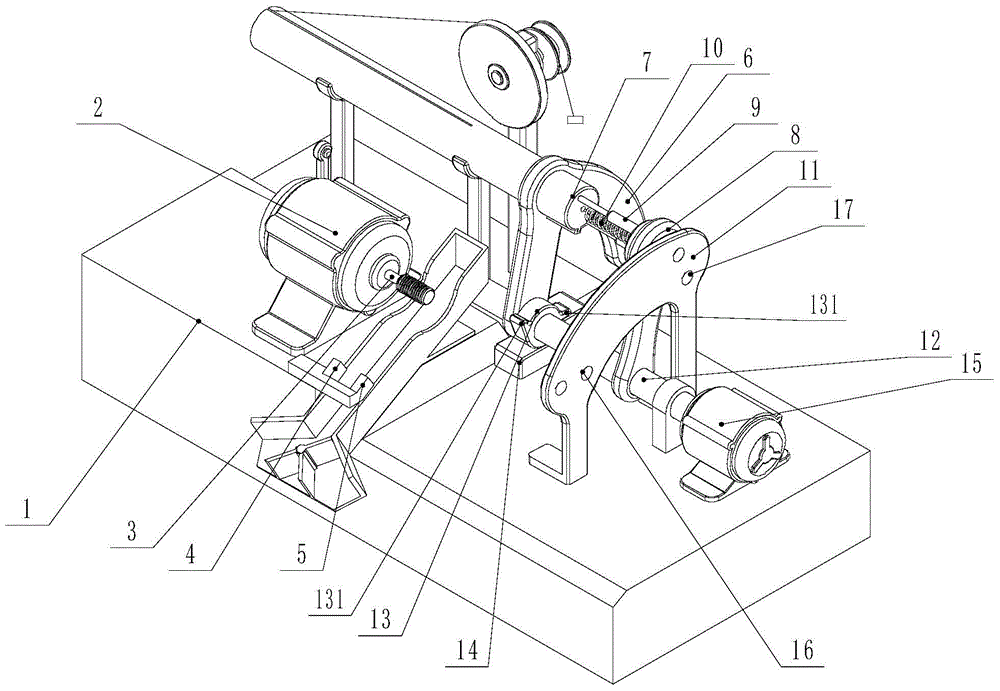

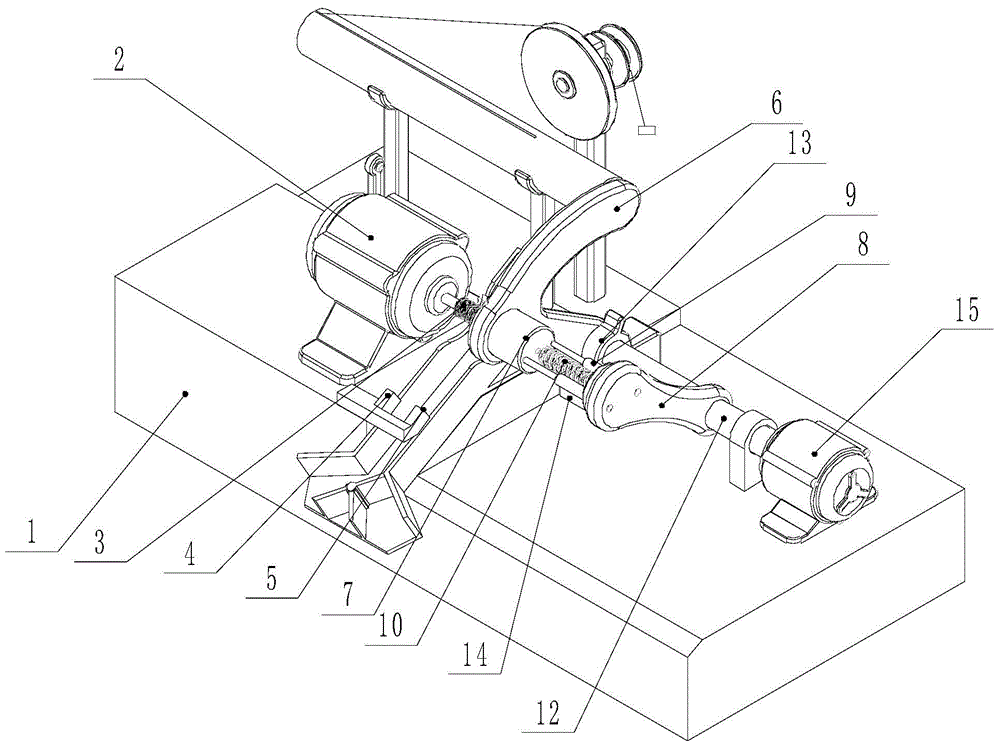

[0026] Such as figure 1 , 2 As shown, a thread detection device of a nut thread inspection machine includes a frame 1; the frame 1 is actually a plate structure; a motor 2 fixed on the frame 1, and an output shaft 3 of the motor 2 is provided with Check the screw thread, the motor 2 can be turned forward and reverse by the switch control; the station switching plate 6 and the swing shaft 12, the swing shaft 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com