Reciprocating-grate biomass repeated-gasification furnace

A multiple gasification and reciprocating technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of energy waste and insufficient biomass combustion, achieve high combustion efficiency, optimize combustion effect, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

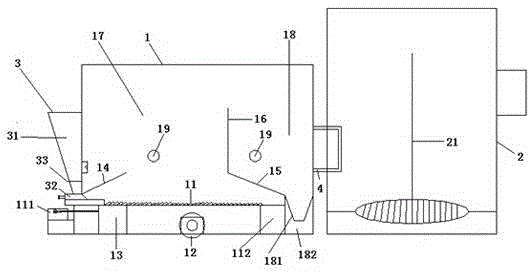

[0027] Pour the biomass particles into the feeder 31 of the feeding device 3, the feeder 31 is an inverted conical structure, and the feeder 31 sends the biomass particles from its outlet to the compression feeder 32, the A feed controller 33 is provided between the material box 31 and the compression feeder 32, which can control the feeding amount in real time and optimize the combustion effect. The compression feeder 32 compresses the biomass particles into biomass blocks and transports them to the corresponding On the reciprocating grate 11 of the connected first furnace 1, the grate drive motor 111 controls the pushing plate of the reciprocating grate 11 to slowly push the biomass blocks forward, so that the biomass blocks are evenly distributed on the reciprocating grate 11, the biomass blocks are burned on the reciprocating fire grate 11, and the air cooler 12 located under the reciprocating fire grate 11 sends the outside air to the reciprocating fire grate 11 to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com