Equipment for machining core iron part of four-way reversing valve and machining technology thereof

A four-way reversing valve and processing equipment technology, applied in the direction of valve device, etc., can solve the problems of backward technology and low production efficiency, and achieve the effect of reducing labor intensity, improving production efficiency and high degree of processing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

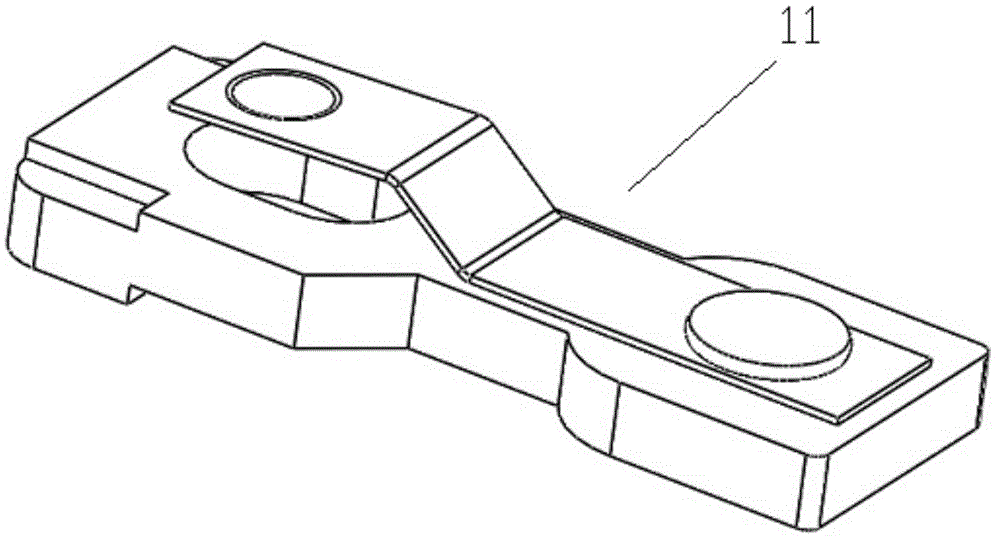

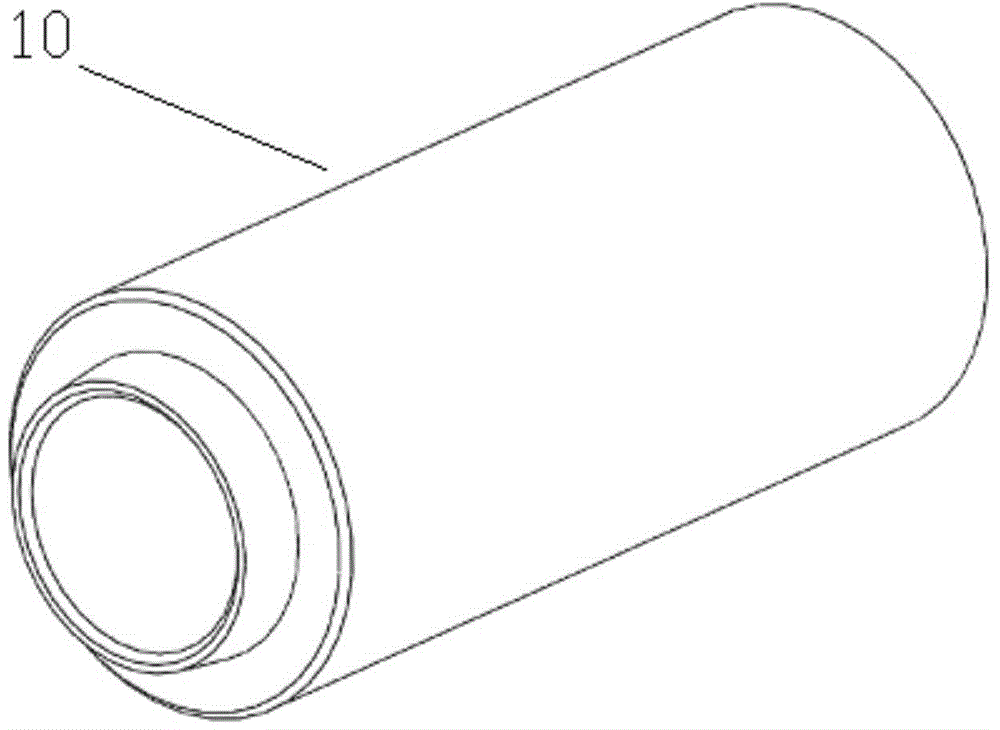

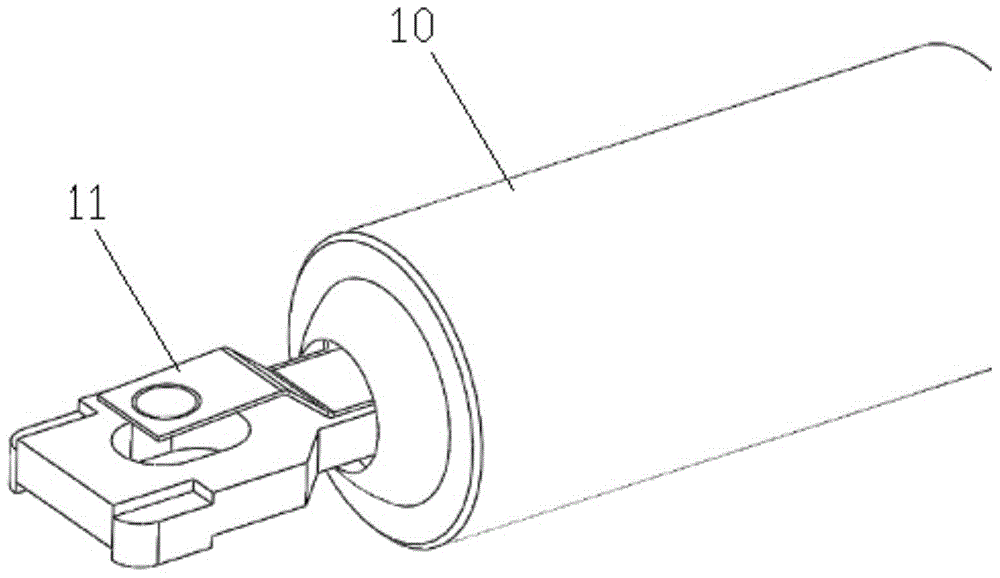

[0026] as attached Figure 4 The shown four-way reversing valve core iron parts processing equipment includes a machine base 1 with a material inlet on one side and a material outlet on the other side. The machine base 1 is provided with a connection between the material inlet and the material outlet Conveyor belt 2 for transporting workpieces, the machine base 1 is provided with a pre-assembly station, a press-fit station and a riveting station sequentially from the feed port to the discharge port. The pre-assembly station is provided with a drag frame part feeding device, a core iron feeding device and a pressing device for combining the drag frame part 11 and the core iron 10 .

[0027] Described core iron feeding device comprises the core iron feeding track 3 that is arranged in parallel with conveyor belt 2; The conveyor belt 2 is parallel to the drag frame component feeding track 5, and the drag frame component feeding track 5 is provided with a push rod 6 for pushing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com