a rigid circuit board

A circuit board, rigid technology, applied in the direction of printed circuit, printed circuit components, printed circuit stress/deformation reduction, etc., can solve the problems of resource waste, increase manufacturing cost, safety hazards, etc., to ensure normal use, reduce costs, The effect of enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

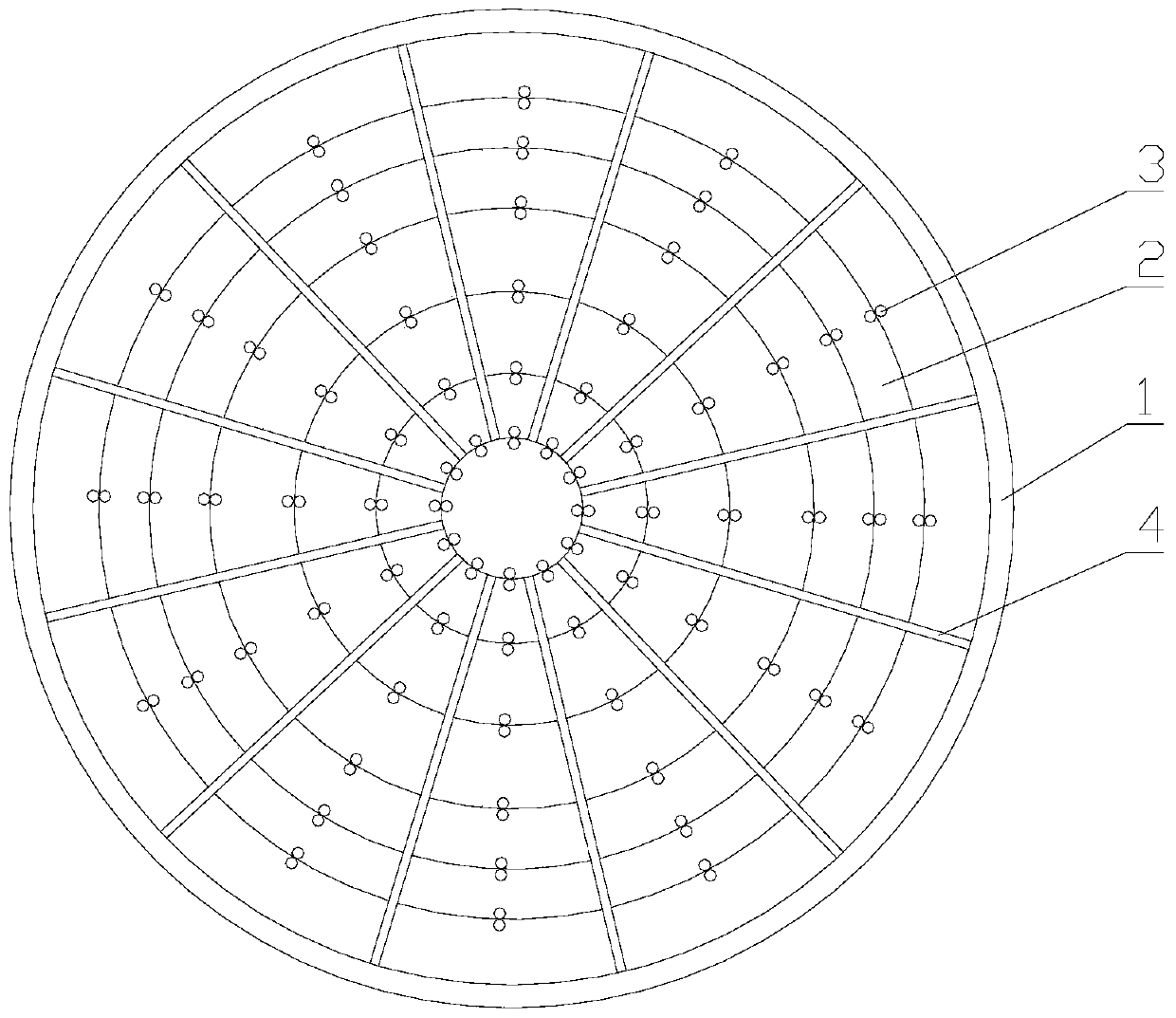

[0014] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0015] Such as figure 1 The shown rigid circuit board of the present invention has a circular substrate 1, on the upper surface of which the circular substrate 1 is uniformly provided with several circular pads 2 distributed concentrically, and the two adjacent circular pads 2 Several welding spots 3 are evenly arranged at the transition area of the pad 2 , and several radial reinforcing ribs 4 are also provided on the several circular pads 2 distributed concentrically. Each welding spot 3 described above is composed of two round spots with equal diameters and mutually circumscribed. The thickness dimension of the reinforcing rib 4 is smaller than the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com