Method for preparing ion imprinting polymer by virtue of ultraviolet induced polymerization at room temperature and application of ion imprinting polymer

An ion imprinting, UV-induced technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of large adsorption capacity, simple operation and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

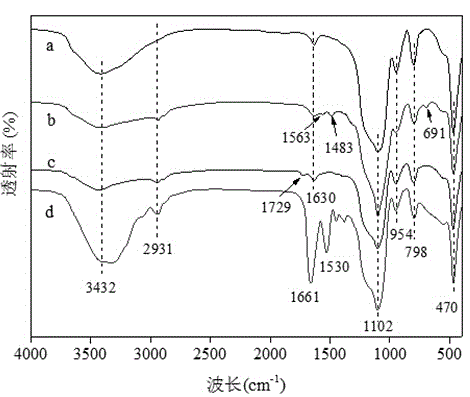

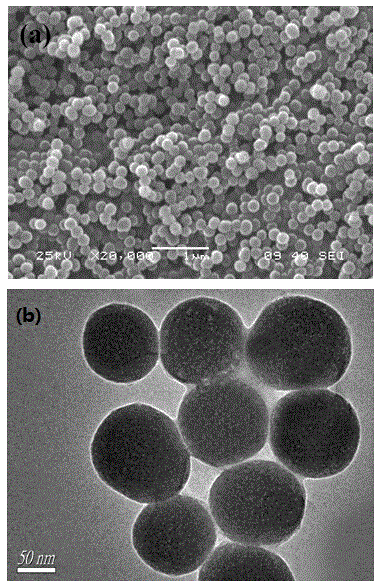

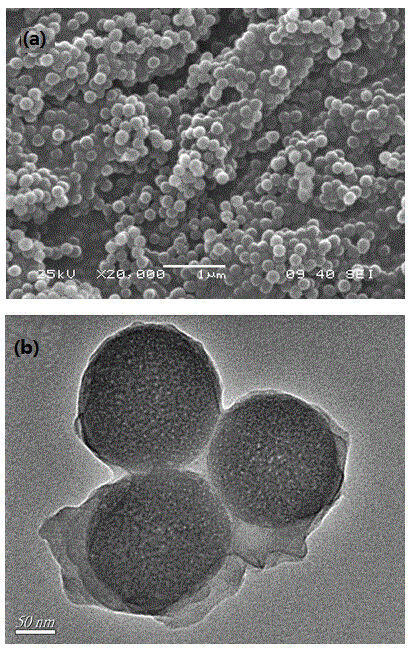

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of matrix material Silica

[0046] In a one-necked flask, add 2 mL of water, 5 mL of ammonia water (28%), and 30 mL of absolute ethanol, respectively, and stir for 10 min with a sealed magnetic force. Then take 3 mL of TEOS and place in a beaker containing 20 mL of absolute ethanol. After mixing evenly, the mixture was carefully and quickly added to a single-necked flask, and the mixture was sealed and stirred for 24 h at room temperature. After the reaction, it was separated by centrifugation, washed several times with ethanol and water until the solution was neutral, placed in a vacuum drying oven, and dried under vacuum at 50 °C for 24 h for later use.

[0047] (2) Silicon dioxide surface vinyl modification (Silica-APTS-AC)

[0048] Put 0.2 g of Silica prepared in step (1) into a round bottom flask, add 50 mL of 3 mol L -1 hydrochloric acid, refluxed for 24 h, then filtered, washed repeatedly with deionized water twice until neutral, vacuum dried a...

Embodiment 2

[0058] (1) Preparation of matrix material Silica

[0059] In a one-necked flask, add 4 mL of water, 10 mL of ammonia water (28%), and 60 mL of absolute ethanol, respectively, and stir for 10 min with a sealed magnetic force. Then take 6 mL of TEOS and place in a beaker containing 40 mL of absolute ethanol. After mixing evenly, the mixture was carefully and quickly added to a single-necked flask, and the mixture was sealed and stirred for 24 h at room temperature. After the reaction, it was separated by centrifugation, washed several times with ethanol and water until the solution was neutral, placed in a vacuum drying oven, and dried under vacuum at 50 °C for 24 h for later use.

[0060] (2) Silicon dioxide surface vinyl modification (Silica-APTS-AC)

[0061] Put 0.5 g of Silica prepared in step (1) into a round bottom flask, add 50 mL of 3 mol L -1 hydrochloric acid, refluxed for 24 h, then filtered, repeatedly washed with deionized water twice to neutrality, vacuum-dried ...

Embodiment 3

[0071] (1) Preparation of matrix material Silica

[0072] In a one-necked flask, add 6 mL of water, 15 mL of ammonia water (28%), and 90 mL of absolute ethanol, respectively, and stir for 10 min with a sealed magnetic force. Then take 9 mL of TEOS and place in a beaker containing 60 mL of absolute ethanol. After mixing evenly, the mixture was carefully and quickly added to a single-necked flask, and the mixture was sealed and stirred for 24 h at room temperature. After the reaction, it was separated by centrifugation, washed several times with ethanol and water until the solution was neutral, placed in a vacuum drying oven, and dried under vacuum at 50 °C for 24 h for later use.

[0073] (2) Silicon dioxide surface vinyl modification (Silica-APTS-AC)

[0074] Place 0.4 g of Silica prepared in step (1) in a round bottom flask, add 50 mL of 3 mol L -1 hydrochloric acid, refluxed for 24 h, then filtered, washed repeatedly with deionized water twice until neutral, vacuum dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com