360 degree space rotary shot blasting machine

A technology of space rotation and shot blasting machine, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of poor product quality, uniform shot blasting of turbine workpieces, etc., and achieve the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

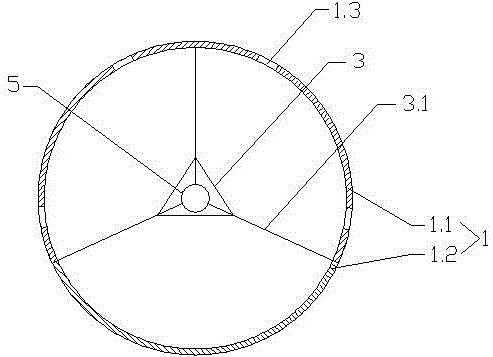

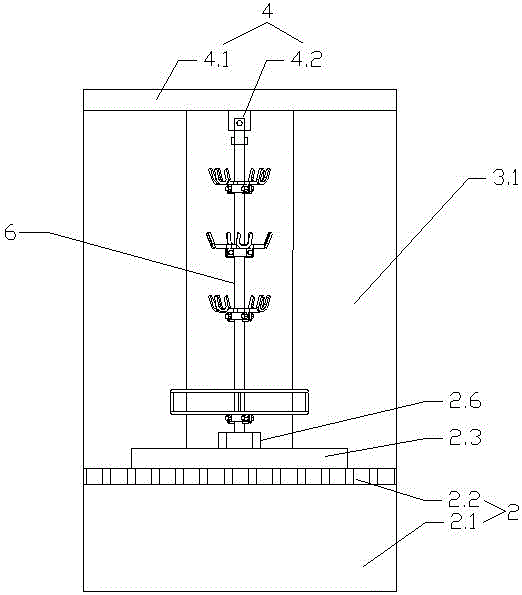

[0033] see Figure 1~Figure 10 , the present invention relates to a 360-degree space rotary shot blasting machine, which includes an outer shell 1 and an inner rotary table.

[0034] The housing 1 includes a fixed housing 1.1 at the rear and a movable housing 1.2 at the front, and the fixed housing 1.1 is provided with a plurality of uniformly arranged blasting inlets 1.3. The fixed casing 1.1 occupies 2 / 3 of the total surface of the casing 1 , and the movable casing 1.2 occupies 1 / 3 of the total surface of the casing 1 .

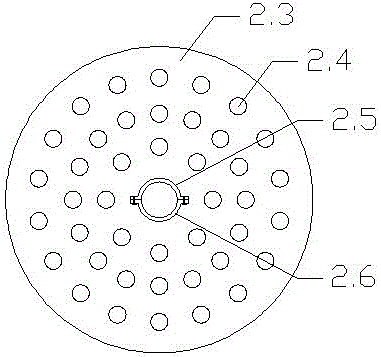

[0035] The rotary table includes a base 2, a support frame 3, a top plate 4 and a rotating shaft 5, the support frame 3 is arranged between the base 2 and the top plate 4, and the support frame 3 divides the entire rotary table into three throwing shafts. Each shot blasting area is provided with a hanging basket 6 arranged vertically.

[0036] The center of the support frame 3 is provided with a vertically arranged rotating shaft 5, the rotating shaft 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com